The Durability of Stainless Steel Seamless Pipe

Stainless steel seamless pipes have gained immense popularity in various industries due to their exceptional durability. With their remarkable resistance to corrosion, high strength, and ability to withstand extreme conditions, stainless steel seamless pipes have become a go-to choice for critical applications. This article aims to explore the factors that contribute to the durability of stainless steel seamless pipes, including their composition, manufacturing process, and key properties that make them highly reliable and long-lasting.

1.Composition of Stainless Steel Seamless Pipes

Stainless steel is an alloy composed primarily of iron, chromium, and varying amounts of other elements such as nickel, molybdenum, and manganese. The presence of chromium, typically in concentrations of at least 10.5%, forms a protective oxide layer on the surface of the steel, known as the passive layer. This passive layer is responsible for the exceptional corrosion resistance of stainless steel, making it highly durable in various environments, including high temperatures, chemicals, and moisture.

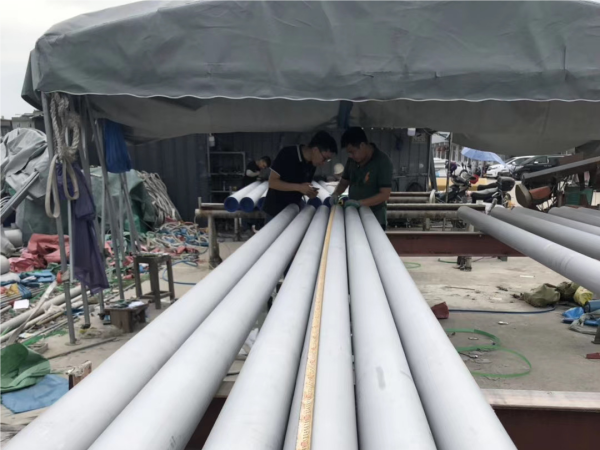

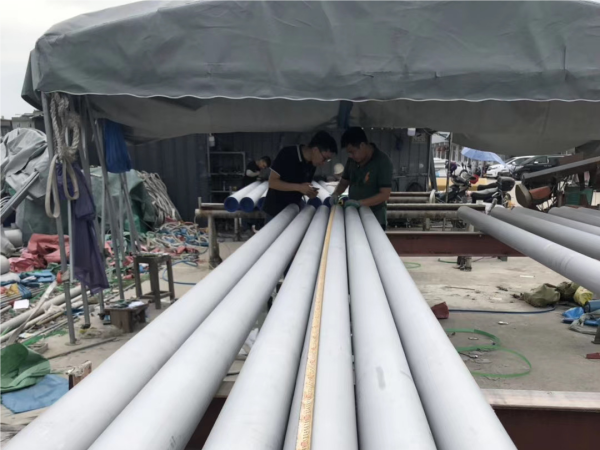

2.Manufacturing Process of Stainless Steel Seamless Pipes

Stainless steel seamless pipes are manufactured using a precise and intricate process to ensure their quality and durability. The key steps in the manufacturing process include:

2.1. Melting and Casting: The raw materials are melted in an electric arc furnace, and the molten metal is cast into molds to form billets or slabs.

2.2. Hot Rolling: The billets or slabs are heated and passed through a series of rolling mills to reduce their thickness and form seamless tubes.

2.3. Heat Treatment: The seamless tubes are subjected to heat treatment processes such as annealing, quenching, and tempering to enhance their mechanical properties and eliminate residual stresses.

2.4. Cold Drawing: The heat-treated tubes are further processed through a cold drawing process, where they are pulled through a die to reduce their diameter and achieve the desired dimensions.

2.5. Finishing Operations: The cold-drawn tubes undergo various finishing operations, including straightening, cutting, and polishing, to ensure their surface finish and dimensional accuracy.

3.Key Properties Contributing to Durability

3.1. Corrosion Resistance: Stainless steel seamless pipes exhibit remarkable resistance to corrosion, making them highly durable in challenging environments. The passive layer formed by chromium on the surface acts as a barrier, preventing the underlying steel from coming into contact with corrosive agents.

3.2. High Strength: Stainless steel seamless pipes possess excellent mechanical properties, including high tensile strength, which allows them to withstand significant internal and external pressures. This strength makes them suitable for applications where structural integrity is crucial.

3.3. Temperature Resistance: Stainless steel seamless pipes exhibit exceptional resistance to high and low temperatures, making them ideal for applications that involve extreme heat or cryogenic conditions. They maintain their mechanical properties even at elevated temperatures, ensuring long-term performance and reliability.

3.4. Fatigue Resistance: Stainless steel seamless pipes have high fatigue strength, meaning they can withstand repeated stress cycles without undergoing fatigue failure. This property is particularly important in applications where pipes are subjected to cyclic loading or vibrations.

4.Applications of Stainless Steel Seamless Pipes

The durability of stainless steel seamless pipes makes them indispensable in various industries. Some prominent applications include:

4.1. Oil and Gas Industry: Stainless steel seamless pipes are widely used in the oil and gas sector, where they transport fluids under high pressures and corrosive conditions. They are commonly used for oil and gas exploration, production, refining, and transportation.

4.2. Chemical and Petrochemical Industry: Stainless steel seamless pipes are resistant to a wide range of chemicals, acids, and alkalis, making them suitable for handling corrosive substances in chemical and petrochemical plants.

4.3. Power Generation: Stainless steel seamless pipes are utilized in power plants, both thermal and nuclear, for applications such as steam pipelines, heat exchangers, and condensers. Their ability to withstand high temperatures and pressure is critical in these settings.

4.4. Food and Beverage Industry: Stainless steel seamless pipes are preferred in food and beverage processing due to their hygienic properties, corrosion resistance, and easy maintenance. They are commonly used for conveying liquids and gases in the production and distribution of food and beverages.

4.5. Construction and Architecture: Stainless steel seamless pipes find applications in construction for structural purposes, including building frames, bridges, and infrastructure. Their durability ensures long-lasting and reliable structures.

5.Maintenance and Longevity

To ensure the longevity of stainless steel seamless pipes, proper maintenance is essential. Regular inspection, cleaning, and preventive measures against corrosion, such as applying protective coatings, can significantly extend their lifespan. Additionally, adherence to relevant industry standards and codes, along with proper installation techniques, is crucial for maximizing the durability of stainless steel seamless pipes.

Conclusion

Stainless steel seamless pipes are renowned for their exceptional durability and reliability. Their composition, manufacturing process, and key properties contribute to their resistance against corrosion, high strength, temperature resistance, and fatigue resistance. These pipes find widespread applications in industries such as oil and gas, chemical and petrochemical, power generation, and construction. With proper maintenance and adherence to industry standards, stainless steel seamless pipes can provide long-lasting and dependable performance, making them an invaluable choice for critical applications.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.