Steel casing pipe is a pipe installed in a drilling wellbore. Its

primary function is to support the wellbore wall, prevent collapse, protect

fluid channels, and extend the service life of the entire system.

Common steel casing pipe materials include galvanized

steel pipe, welded

steel pipe, and seamless

steel pipe. Depending on the specific working conditions, these

materials offer advantages in strength, sealing, corrosion resistance, and

maintainability:

Welded casing pipe offers advantages such

as high strength and good sealing, but is difficult to disassemble. This type

of steel casing pipe is generally used in projects such as connecting the same

natural gas pipeline.

Seamless

casing pipe has a smooth surface, uniform inner

and outer walls, and is resistant to rust. It is generally used for connecting

tap water and natural gas pipelines.

Galvanized casing pipe offers excellent

rust resistance and is suitable for applications such as outdoor drainage, wall

penetration protection, and communication cable protection.

Steel Casing Pipe Specification

Specification: 1/2" to 24 Inches

Length: 1m, 12m, 6.4m, 6m, 13m

Equivalent: API 5CT J55/K55, N80-1

Linings & Coatings: Liquid epoxy,

Polyurethane, & FBE

International Standard: API 5CT, IS 5433, ISO

11960, SY/T6194, GB/T 9711.1

Types: BTC, EUE. NUE

Application: Oil well casing pipe, natural

gas pipeline, geothermal well, water

well casing pipe, structural protection pipe

API 5CT Spec Steel Casing Pipe Weight Chart

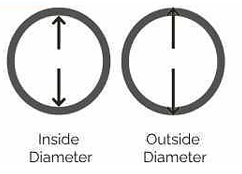

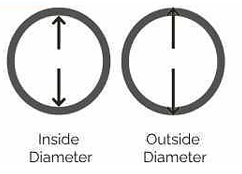

The following is a table of some steel

casing pipe weights according to API 5CT standard, covering unit weights

(lbs/ft) corresponding to different outside diameters (OD) and wall

thicknesses:

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

4 1/2

|

114.30

|

26.50

|

3.240

|

82.30

|

3.115

|

79.12

|

1.02

|

|

24.60

|

3.380

|

85.85

|

3.255

|

82.68

|

1.11

|

|

21.60

|

3.500

|

88.90

|

3.375

|

85.73

|

1.19

|

|

18.80

|

3.640

|

92.46

|

3.515

|

89.28

|

1.29

|

|

17.70

|

3.696

|

93.88

|

3.571

|

90.70

|

1.33

|

|

16.90

|

3.740

|

95.00

|

3.615

|

91.82

|

1.36

|

|

16.60

|

3.754

|

95.35

|

3.629

|

92.18

|

1.37

|

|

15.10

|

3.826

|

97.18

|

3.701

|

94.01

|

1.42

|

|

13.50

|

3.920

|

99.57

|

3.795

|

96.39

|

1.49

|

|

12.60

|

3.958

|

100.53

|

3.833

|

97.36

|

1.52

|

|

11.60

|

4.000

|

101.60

|

3.875

|

98.43

|

1.55

|

|

10.50

|

4.052

|

102.92

|

3.927

|

99.75

|

1.59

|

|

9.50

|

4.090

|

103.89

|

3.965

|

100.71

|

1.63

|

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

5

|

127.00

|

32.00

|

3.620

|

91.95

|

3.495

|

88.77

|

1.27

|

|

26.70

|

3.876

|

98.45

|

3.751

|

95.28

|

1.46

|

|

24.20

|

4.000

|

101.60

|

3.875

|

98.43

|

1.55

|

|

23.20

|

4.044

|

102.72

|

3.919

|

99.54

|

1.59

|

|

21.40

|

4.126

|

104.80

|

4.001

|

101.63

|

1.65

|

|

20.80

|

4.156

|

105.56

|

4.031

|

102.39

|

1.68

|

|

20.30

|

4.184

|

106.27

|

4.059

|

103.10

|

1.70

|

|

18.00

|

4.276

|

108.61

|

4.151

|

105.44

|

1.78

|

|

15.00

|

4.408

|

111.96

|

4.283

|

108.79

|

1.89

|

|

13.00

|

4.494

|

114.15

|

4.369

|

110.97

|

1.96

|

|

11.50

|

4.560

|

115.82

|

4.435

|

112.65

|

2.02

|

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

5 1/2

|

139.70

|

39.30

|

4.044

|

102.72

|

3.919

|

99.54

|

1.59

|

|

36.40

|

4.090

|

103.89

|

3.965

|

100.71

|

1.62

|

|

32.30

|

4.276

|

108.61

|

4.151

|

105.44

|

1.78

|

|

29.70

|

4.376

|

111.15

|

4.251

|

107.98

|

1.86

|

|

28.40

|

4.440

|

112.78

|

4.315

|

109.60

|

1.91

|

|

26.00

|

4.548

|

115.52

|

4.423

|

112.34

|

2.01

|

|

23.00

|

4.670

|

118.62

|

4.545

|

115.44

|

2.12

|

|

20.00

|

4.778

|

121.36

|

4.653

|

118.19

|

2.22

|

|

17.00

|

4.892

|

124.26

|

4.767

|

121.08

|

2.32

|

|

15.50

|

4.950

|

125.73

|

4.825

|

122.56

|

2.38

|

|

14.00

|

5.012

|

127.30

|

4.887

|

124.13

|

2.44

|

|

13.00

|

5.044

|

128.12

|

4.919

|

124.94

|

2.47

|

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

6

|

152.40

|

26.00

|

5.007

|

127.18

|

4.882

|

124.00

|

2.56

|

|

23.00

|

5.115

|

129.92

|

4.990

|

126.75

|

2.67

|

|

20.00

|

5.227

|

132.77

|

5.102

|

129.58

|

2.78

|

|

18.00

|

5.299

|

134.59

|

5.174

|

131.41

|

2.86

|

|

15.00

|

5.399

|

137.13

|

5.274

|

134.00

|

2.98

|

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

6 5/8

|

166.28

|

69.63

|

4.375

|

111.13

|

4.250

|

107.95

|

1.86

|

|

43.20

|

5.250

|

133.35

|

5.125

|

130.17

|

2.81

|

|

35.00

|

5.450

|

138.43

|

5.325

|

135.25

|

3.02

|

|

32.00

|

5.550

|

140.97

|

5.425

|

137.79

|

3.13

|

|

28.00

|

5.666

|

143.92

|

5.541

|

140.74

|

3.26

|

|

24.00

|

5.796

|

147.22

|

5.671

|

144.04

|

3.41

|

|

20.00

|

5.924

|

150.47

|

5.799

|

147.29

|

3.55

|

|

17.00

|

6.010

|

152.65

|

5.885

|

149.47

|

3.66

|

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

7

|

177.80

|

66.50

|

5.040

|

128.02

|

4.915

|

124.84

|

2.47

|

|

58.00

|

5.240

|

133.10

|

5.115

|

129.92

|

2.67

|

|

56.10

|

5.376

|

136.55

|

5.251

|

133.38

|

2.81

|

|

49.50

|

5.540

|

140.72

|

5.415

|

137.54

|

2.98

|

|

45.40

|

5.660

|

143.76

|

5.535

|

140.59

|

3.11

|

|

44.00

|

5.720

|

145.29

|

5.595

|

142.11

|

3.18

|

|

42.70

|

5.750

|

146.05

|

5.625

|

142.88

|

3.21

|

|

41.00

|

5.820

|

147.83

|

5.695

|

144.65

|

3.29

|

|

38.00

|

5.920

|

150.37

|

5.795

|

147.19

|

3.40

|

|

35.00

|

6.004

|

152.50

|

5.879

|

149.33

|

3.50

|

|

32.00

|

6.094

|

154.79

|

5.969

|

151.61

|

3.61

|

|

29.00

|

6.184

|

157.07

|

6.059

|

153.90

|

3.71

|

|

26.00

|

6.276

|

159.41

|

6.151

|

156.24

|

3.83

|

|

23.00

|

6.366

|

161.70

|

6.241

|

158.52

|

3.94

|

|

20.00

|

6.456

|

163.98

|

6.331

|

160.81

|

4.05

|

|

17.00

|

6.538

|

166.07

|

6.413

|

162.89

|

4.15

|

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

7 5/8

|

193.68

|

52.80

|

6.201

|

157.81

|

6.000

|

152.40

|

3.74

|

|

55.75

|

6.176

|

156.87

|

6.000

|

152.40

|

3.74

|

|

51.20

|

6.249

|

158.72

|

6.125

|

155.58

|

3.80

|

|

47.10

|

6.375

|

161.93

|

6.250

|

158.75

|

3.95

|

|

45.30

|

6.435

|

163.45

|

6.310

|

160.27

|

4.02

|

|

42.80

|

6.501

|

165.13

|

6.376

|

161.95

|

4.11

|

|

46.10

|

6.560

|

166.62

|

6.500

|

165.10

|

4.18

|

|

39.00

|

6.625

|

168.28

|

6.500

|

165.10

|

4.26

|

|

33.70

|

6.765

|

171.83

|

6.640

|

168.66

|

4.45

|

|

29.70

|

6.875

|

174.63

|

6.750

|

171.45

|

4.59

|

|

26.40

|

6.969

|

177.01

|

6.844

|

173.84

|

4.72

|

|

24.00

|

7.025

|

178.44

|

6.900

|

175.26

|

4.79

|

|

20.00

|

7.125

|

180.98

|

7.000

|

177.80

|

4.93

|

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

8 5/8

|

219.08

|

52.00

|

7.435

|

188.85

|

7.310

|

185.67

|

5.37

|

|

49.00

|

7.511

|

190.78

|

7.386

|

187.60

|

5.48

|

|

44.00

|

7.625

|

193.68

|

7.500

|

190.50

|

5.65

|

|

7.636

|

193.95

|

7.500

|

190.50

|

5.66

|

5.66

|

|

40.00

|

7.725

|

196.22

|

7.600

|

193.04

|

5.80

|

|

36.00

|

7.825

|

198.76

|

7.700

|

195.58

|

5.95

|

|

32.00

|

7.921

|

201.19

|

7.796

|

198.02

|

6.09

|

|

28.00

|

8.017

|

203.63

|

7.892

|

200.46

|

6.24

|

|

24.00

|

8.097

|

205.66

|

7.972

|

202.49

|

6.37

|

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

9 5/8

|

244.48

|

71.80

|

8.125

|

206.38

|

7.969

|

202.41

|

6.41

|

|

70.30

|

8.157

|

207.19

|

8.001

|

203.23

|

6.46

|

|

64.90

|

8.281

|

210.34

|

8.125

|

206.38

|

6.66

|

|

61.10

|

8.375

|

212.73

|

8.219

|

208.76

|

6.81

|

|

59.40

|

8.407

|

213.54

|

8.251

|

209.58

|

6.87

|

|

58.40

|

8.435

|

214.25

|

8.279

|

210.29

|

6.91

|

|

53.50

|

8.535

|

216.79

|

8.379

|

212.83

|

7.08

|

|

59.20

|

8.560

|

217.42

|

8.500

|

215.90

|

7.12

|

|

47.00

|

8.681

|

220.50

|

8.525

|

216.54

|

7.32

|

|

62.80

|

8.625

|

219.08

|

8.500

|

215.90

|

7.23

|

|

43.50

|

8.755

|

222.38

|

8.599

|

218.41

|

7.45

|

|

40.00

|

8.835

|

224.41

|

8.679

|

220.45

|

7.58

|

|

38.00

|

8.885

|

225.68

|

8.760

|

222.50

|

7.67

|

|

36.00

|

8.921

|

226.59

|

8.765

|

222.63

|

7.73

|

|

32.30

|

9.001

|

228.63

|

8.845

|

224.66

|

7.87

|

|

29.30

|

9.063

|

230.20

|

8.907

|

226.24

|

7.98

|

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

10 3/4

|

273.05

|

81.00

|

9.094

|

230.99

|

8.31

|

211.06

|

6.41

|

|

79.20

|

9.126

|

231.80

|

8.37

|

212.61

|

6.50

|

|

76.00

|

9.194

|

233.53

|

8.49

|

215.27

|

6.72

|

|

73.20

|

9.250

|

234.95

|

8.59

|

218.19

|

7.02

|

|

71.10

|

9.294

|

236.07

|

8.67

|

220.17

|

7.28

|

|

65.70

|

9.404

|

238.86

|

8.88

|

225.69

|

8.02

|

|

60.70

|

9.504

|

241.40

|

9.06

|

230.13

|

8.31

|

|

55.50

|

9.604

|

243.94

|

9.25

|

234.32

|

8.59

|

|

51.00

|

9.694

|

246.23

|

9.42

|

238.65

|

8.88

|

|

45.50

|

9.794

|

248.77

|

9.62

|

244.13

|

9.02

|

|

40.50

|

9.894

|

251.31

|

9.81

|

249.51

|

9.35

|

|

35.75

|

10.136

|

257.45

|

9.98

|

254.78

|

9.70

|

|

32.75

|

10.192

|

258.88

|

10.09

|

256.85

|

9.98

|

|

OD

(in)

|

OD

(mm)

|

Weight

(lbs/ft)

|

ID

(inches)

|

ID

(mm)

|

Drift

(inches)

|

Drift

(mm)

|

Capacity

(bbl/100ft)

|

|

11 3/4

|

298.45

|

95.00

|

9.968

|

253.19

|

9.812

|

249.26

|

9.96

|

|

87.20

|

10.126

|

257.20

|

9.970

|

253.19

|

10.27

|

|

83.00

|

10.212

|

259.38

|

10.056

|

255.20

|

10.44

|

|

80.50

|

10.282

|

261.16

|

10.126

|

257.20

|

10.44

|

|

79.00

|

10.344

|

262.74

|

10.188

|

258.67

|

10.58

|

|

76.00

|

10.358

|

263.09

|

10.202

|

259.03

|

10.71

|

|

75.00

|

10.376

|

263.55

|

10.220

|

259.51

|

10.74

|

|

73.60

|

10.430

|

264.92

|

10.274

|

260.82

|

10.78

|

|

71.00

|

10.526

|

267.36

|

10.370

|

263.40

|

10.89

|

|

66.70

|

10.616

|

269.65

|

10.460

|

265.66

|

11.03

|

|

65.00

|

10.724

|

272.39

|

10.568

|

268.11

|

11.08

|

|

60.00

|

10.844

|

275.44

|

10.688

|

271.39

|

11.27

|

|

54.00

|

10.880

|

276.35

|

10.724

|

272.39

|

11.50

|

|

47.00

|

11.000

|

279.40

|

10.844

|

275.44

|

11.75

|

|

71.80

|

10.711

|

272.06

|

10.625

|

269.88

|

11.00

|

|

42.00

|

11.084

|

281.53

|

10.928

|

277.57

|

11.93

|

|

38.00

|

11.150

|

283.21

|

10.994

|

279.25

|

12.08

|

Note:

The above data is a partial list of common

weights. Actual specifications depend on wall thickness and material grade.

To quickly estimate steel casing pipe

weight during selection or quotation, use the steel

casing pipe weight calculation formula.

Impact of Steel Casing Pipe Weight

1. Impact on Pressure Bearing Capacity and

Strength

Heavier steel casing pipe generally has

thicker walls, resulting in greater resistance to compression, bending, and

deformation, effectively preventing wellbore collapse.

2. Impact on Construction and Installation

Heavier steel casing pipe is more difficult

to hoist, transport, and lower into the wellbore, placing higher demands on

equipment.

Lightweight steel casing pipe is easier to

install and more efficient, making it suitable for shallow wells or temporary

projects.

3. Impact on Transportation and Cost

Heavy steel casing pipe uses more steel,

resulting in higher material and transportation costs.

Lightweight steel casing pipe is less

expensive and suitable for projects with limited budgets.

4. Impact on Service Life and Sealing

Heavier steel casing pipe has thicker

walls, better corrosion and wear resistance, longer service life, and tighter

seals at joints, preventing leaks.

Conclusion

Steel casing pipe is an indispensable

component in drilling and pipeline engineering. Its weight determines its

strength, construction difficulty, cost, and applicable scenarios.

Understanding the weight table for steel casing pipe not only helps engineers

accurately select the right type during the design phase but also effectively

manage costs and risks during construction. When selecting a type,

comprehensive considerations should be made based on the project's pressure

level, well depth, environmental conditions, and budget to achieve the optimal

balance between safety and cost effectiveness.

Read more: Steel Casing Pipe Size Chart or One-Piece vs. Split Steel Casing Pipe

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.