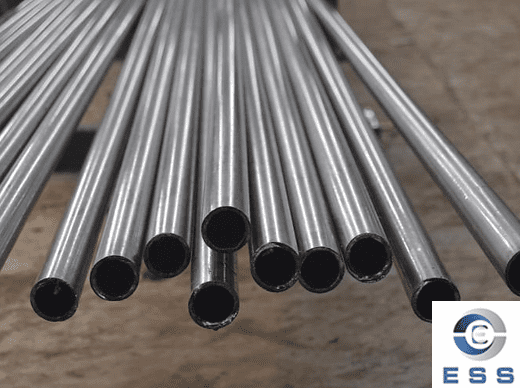

Stainless steel precision tube, with its

unique performance advantages, holds a vital position in high-end

manufacturing, precision engineering, and specialized applications. However,

this material is not without its flaws and has potential drawbacks in certain

areas. The following provides a comprehensive analysis from various

perspectives:

Advantages of Stainless Steel Precision

Tube

1. Superior Material Properties

Stainless steel precision tube contains

elements such as chromium (Cr), nickel (Ni), and titanium (Ti).

Chromium (Cr ≥ 10.5%): Significantly improves the strength, hardness, wear resistance,

oxidation resistance, and corrosion resistance of stainless steel precision

tube.

Nickel (Ni 8%-12%): Enhances strength,

maintains stainless steel's toughness, and provides high corrosion resistance

to acids and alkalis.

Molybdenum (Mo 2%-3%): Significantly

improves resistance to pitting and crevice corrosion (commonly found in

medical-grade precision tube).

Titanium (Ti): Ensures the tubing's

tightness and prevents intergranular corrosion.

2. High Dimensional Precision

Using cold

drawing/cold rolling, or mandrel-less rolling processes, we ensure

precise control of wall thickness and diameter.

Common tolerances reach ±0.01mm, and some high-end applications can even reach ±0.005mm, ensuring extremely tight tolerances.

Roundness error is less than 0.02mm, making

it ideal for precision assembly and micro-flow control.

3. Excellent Surface Quality

Inner and outer surface roughness (Ra) can

be as low as 0.2 μm, far superior to ordinary welded

steel pipes.

The inner wall is smooth and burr-free,

reducing fluid resistance and improving conveying efficiency.

The pipe body is scratch-free and has a

uniform and smooth wall thickness. The pipe ends are intact and burr-free, the

inner wall is flat, and the welds are free of leaks and pinholes.

4. Excellent Overall Performance

High strength and pressure-bearing

capacity, typically capable of withstanding high pressures of 60–100 MPa;

Can be cold-bent, flared, or flattened

without cracking or wrinkling, and can undergo various complex deformation and

machining processes;

5. Economical and Environmentally

Friendly

Stainless steel precision tubes have a long

service life and are more durable than materials such as copper and aluminum;

Low maintenance costs and corrosion

resistance reduce the need for routine maintenance;

Recyclable and reusable at over 90%, they

are both practical and environmentally friendly.

6. Wide Range of Applications

By tube size:

Small-diameter stainless steel precision

tubes (0.3mm–20mm) are used in optical scale circuits,

thermal instruments, and automation instruments;

Large-diameter stainless steel precision

tubes (20mm–200mm) are used in industrial piping,

nuclear power, power generation, and sewage treatment equipment.

By cross-sectional shape:

Round and square tubes can be used for

water dispenser outlet pipes, water purification equipment filter cartridges,

lighting components, etc.;

Special-shaped tubes can be used for

bathroom shower fixtures, faucet pipes, gas water heater heat exchange tubes,

mechanical equipment structural tubes, etc.

Disadvantages of Stainless Steel

Precision tube

1. High Cost

Stainless steel raw materials (such as

316L) are significantly more expensive than carbon steel, averaging 2–4 times higher.

Precision processing (cold drawing,

polishing, pickling and passivation, etc.) adds additional costs, resulting in

a market price generally ranging from $3,500–6,000 per

ton.

2. Poor Weldability

Precision tubes have thin walls, making

welding prone to defects such as pores, cracks, and weld nubs.

Specialized processes and equipment, such

as argon arc welding (TIG) and laser welding, are required to ensure quality.

Highly skilled construction personnel are

required, increasing the difficulty and cost of construction.

3. Susceptibility to Stress Corrosion

Stainless

steel tubes may be susceptible to stress corrosion in certain

environments (such as those containing chloride ions). This can lead to cracks

or even breakage in the pipe.

4. Difficulty in Surface Treatment

Compared to carbon

steel pipes and aluminum pipes, stainless steel precision tubes have a

higher surface hardness and higher processing costs.

High-quality polishing requires multiple

steps, otherwise the aesthetics and corrosion resistance are affected.

Mirror-grade precision tubes often require

electrolytic polishing, which is complex and expensive.

Summary

Stainless steel precision tubes, with their

high precision, high strength, excellent corrosion resistance, and wide

applicability, hold an irreplaceable position in high-end industries such as

medical, aviation, automotive, and semiconductors. However, they also have

limitations, such as high cost, difficulty in welding, and susceptibility to

chloride ion stress corrosion. In practical applications, the decision to use

them should be made based on comprehensive considerations based on the specific

situation.

Read more: What Are The Classifications of Stainless Steel Precision Tubes? or What Is A Stainless Steel Precision Tube?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.