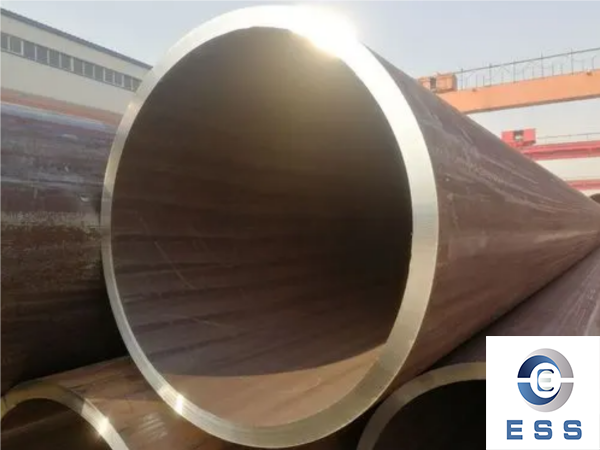

Main production process description of LSAW steel pipe

The straight seam welded pipe production line is a process that heats or pressurizes the steel plate to be welded, or both, with or without filling material, so that the material of the steel plate is bonded between atoms. Permanent connection.

The pipe obtained by straight seam welding on welding equipment is called straight seam welded pipe (such as

ERW pipe, LSAW pipe). According to different uses, there are different production processes.

Main production process description of straight seam welded pipe

1. Plate inspection: After the steel plates used to manufacture large-diameter submerged arc welded straight seam steel pipes enter the production line, the entire plate is first subjected to ultrasonic inspection;

2. Edge milling: Use an edge milling machine to perform double-sided milling on both sides of the steel plate to achieve the required plate width, plate edge parallelism and bevel shape;

3. Pre-bending: Use a pre-bending machine to pre-bend the edge of the plate so that the edge of the plate has a required curvature;

4. Forming: On the JCO forming machine, half of the pre-bent steel plate is first pressed into a "J" shape through multiple step-by-step stampings. Then use the same method to bend the other half of the steel plate and press it into a "C" shape, and finally form an open "O" shape.

5. Pre-welding: The formed straight seam welded steel pipe welds are continuously welded using gas shielded welding (MAG);

6. Internal welding: series multi-wire submerged arc welding (up to four wires) is used to weld the inside of the straight seam steel pipe;

7. External welding: series multi-wire submerged arc welding is used to weld the outside of the straight seam submerged arc welded steel pipe;

8. Ultrasonic flaw detection I: 100% flaw detection on the internal and external welds of the straight seam welded steel pipe and the base metal on both sides of the weld;

9. X-ray flaw detection I: 100% X-ray industrial TV flaw detection of internal and external welds, using an image processing system to ensure the sensitivity of flaw detection;

10. Diameter expansion: The entire length of the submerged arc welded straight seam steel pipe is expanded to improve the dimensional accuracy of the steel pipe and improve the distribution of stress within the steel pipe;

11. Hydraulic pressure test: On the hydraulic pressure testing machine, the expanded steel pipes are inspected one by one to ensure that the steel pipes meet the test pressure required by the standard. The machine has automatic recording and storage functions;

12. Chamfering: Process the pipe end of the qualified steel pipe to achieve the required pipe end bevel size;

13. Ultrasonic flaw detection 2: Carry out ultrasonic flaw detection one by one to check possible defects after diameter expansion and hydraulic pressure of the straight seam welded steel pipe;

14. X-ray flaw detection 2: Conduct X-ray industrial television flaw detection and pipe end welding seam photography on the steel pipe after diameter expansion and hydraulic pressure test;

15. Magnetic particle inspection of pipe ends: This inspection is performed to find defects at pipe ends;

16. Anti-corrosion and coating: Qualified steel pipes are anti-corrosion and coated according to user requirements.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.