Knowledge to clean seamless elbows

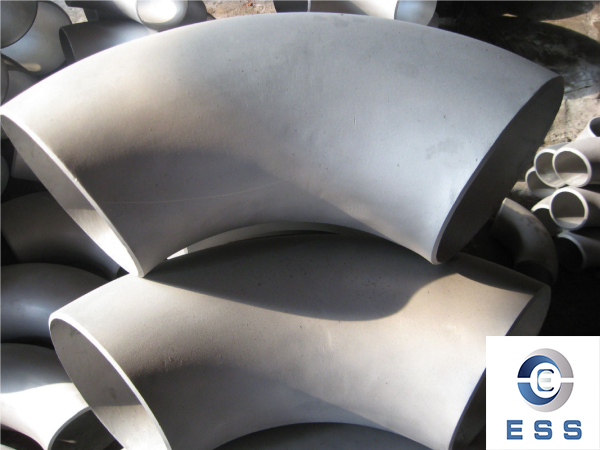

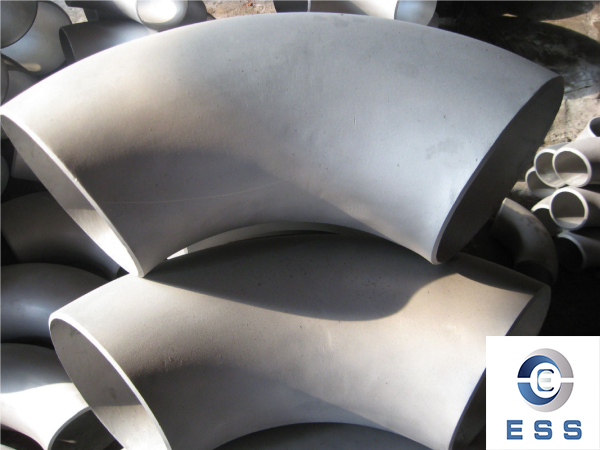

A kind of pipe fitting used in the turns of high-pressure pipelines is called seamless elbow. It accounts for a large proportion, about 80%, of all pipe fittings used in high-pressure piping systems. Generally, seamless elbows are made of high-quality cast steel, stainless steel or alloy steel, which allows the seamless elbow to withstand high pressure in various high-pressure pipelines and can withstand the corrosion of fluids in the pipeline, so the wall thickness of the seamless elbow Thicker than ordinary elbows, or the high-pressure strength of the material is higher than ordinary elbows. Pipe systems such as oil transportation pipelines, liquefied gas pipelines, water pipes, boiler pipes, etc. are the occasions where seamless elbows are used.

However, in actual use of seamless elbows, due to factors such as the transportation medium and surrounding environment (temperature, humidity, dust), the seamless elbows will become dirty and lose their previous brightness. So, in this case, how should the seamless elbow be cleaned? What should you pay attention to when cleaning seamless elbows?

1. Solvents and emulsions are used to clean elbows. Oil, grease, dust, lubricants and similar organic matter can be removed when using these two types of cleaners to clean dirt on the surface of ceramic elbows and ceramic composite elbows, but they cannot remove rust, oxide scale, solder flux, etc. on steel surfaces. Therefore, it is only used as an auxiliary material and not as a main preservative.

2. Remove rust from seamless elbows. Mainly use wire brushes to polish the steel surface, which can remove loose or warped oxide scale, rust, welding slag, etc. Manual rust removal can reach Sa2 level, and strong rust removal can reach Sa; if there is hard iron oxide scale on the steel surface, The rust is not obvious when removed with a wire brush, etc., and the depth of the anchor pattern required for anti-corrosion construction cannot be achieved.

3. For pickling of seamless elbows, under normal circumstances, two methods, chemical and electrolytic, are used for pickling. It is suitable for elbows with different pickling methods and has different effects, such as: wear-resistant elbows, used for grinding ceramic elbows, ceramic elbows and ceramic composite elbows, only chemical pickling is used for anti-corrosion, which can remove oxide scale, Rust, old coating. Sometimes, it can be used for reprocessing after sandblasting and rust removal; chemical cleaning can make the surface reach a certain degree of cleanliness and roughness, but its anchor pattern is shallow and can easily pollute the environment. When pickling seamless elbows, you must choose carefully. Don't make choices based on your own ideas. Not only will it not clean the elbow, it will also affect the performance and use of the elbow. Life expectancy will be affected. In severe cases, elbow leakage may even occur during use, causing the manufacturer to suffer economic losses and casualties.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.