A Comprehensive Introduction to Hollow Structural Section

The hollow structural section(HSS) is a versatile steel product for fabrication, building, and mechanical purposes. They have a flat and smooth surface along the edges which makes them much easier to connect to other metal sections. The most common uses of HSS are for building columns, frames and beams due to its high strength to weight ratio and the ability to handle high temperature and pressure in a harsh environment. Some other common applications of hollow structural steel are staircases, bridges, trusses, gates, platforms, storage facilities, fencing, guardrails, decking, building facades, roof purlins, protection panels, architectural designs, and many more.

Benefits of using Hollow Structural Sections (HSS)

1. High strength-to-weight ratio

Hollow Structural Sections are able to provide a high compression performance and greater weight saving as they have a high radil of gyration on both axes. This has made them become the most economical and efficient structural member.

2.Less surface area for coating

Hollow Structural Sections require less surface preparation, coating, and painting as they only possess approximately two-thirds of the surface area of the open section in a comparable capacity.

3.Closed section

The closed section of hollow structural sections provides higher cleanliness as they have a minimal surface to collect debris and dust. This has made them an ideal choice for food processing factories or other clean facilities. Closed sections are also good for torsional loads resistance.

4.Low project costs

Hollow structural sections are manufactured with lesser steel material when compared to solid steel products as HSS has an unfilled core. Their high strength-to-weight ratio also allows them to span at a greater distance than solid steel products. This has reduced the number of steel required throughout the whole project. In this case, you can enjoy a lower material cost when using hollow structural sections.

5.High aesthetic appeal

Hollow structural sections have a high aesthetic appeal and are favored architecturally due to their smooth surfaces, closed sections, and rounded corners.

6.Flexible & Highly customizable

They can be modified easily into desired shapes and manufactured in various sizes to match your requirements. The material of HSS also can be recycled easily.

7.Utilized interior space

The interior space of a hollow section can actually provide improvement to the building structure. For example, you can put components of a ventilation system inside the beams or fill the space with concrete to improve their bearing capabilities and be more fire-resistant.

Types of Hollow Structural Sections (HSS)

There are three main types of steel hollow profiles (structural steel tubes): RHS (rectangular hollow profiles), SHS (square hollow profiles) and CHS (round hollow profiles). Each type of hollow profile has its own properties and is used for a specific purpose.

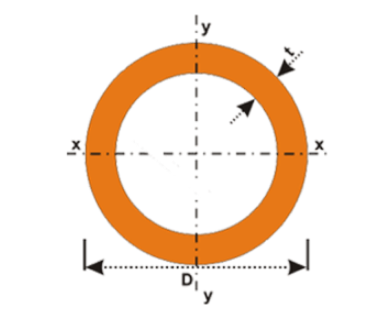

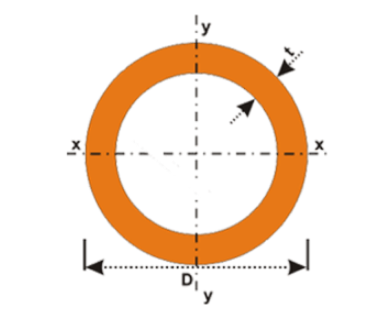

CHS – Round hollow profiles: aesthetics and strength

Circular hollow profiles (CHS), also called round steel pipes, are the first form of hollow profiles. Commonly used in a wide range of structural, mechanical and construction areas. CHS's clean, consistent lines, absence of any protruding edges, and smoothness make it a popular architectural choice for a beautiful appearance in a variety of applications.

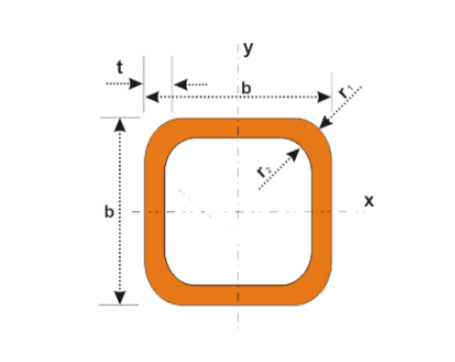

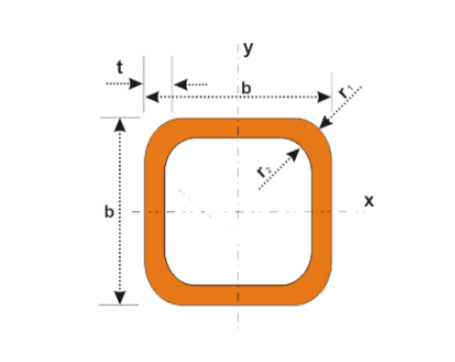

SHS – Square Hollow Section: Symmetry, balanced strength and aesthetics

Square Hollow Sections (SHS) also called square tubes are another popular type of structural steel tubes and are a middle man between RHS and CHS in terms of properties, appearance and structural performance. SHS has a flat surface, is also economical for joining and welding, and provides high cleanliness. Minimal lines and required edge processing. SHS also shares the properties of CHS with its symmetrical appearance, resulting in an equilateral square hollow profile - as opposed to a round profile. SHS offers the ideal balance of strength, functionality and aesthetic appearance for numerous applications requiring all three.

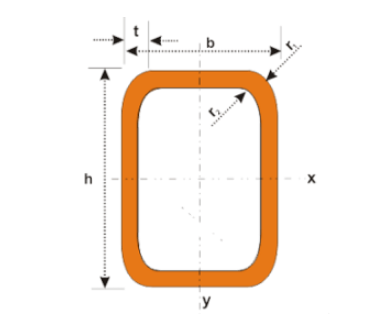

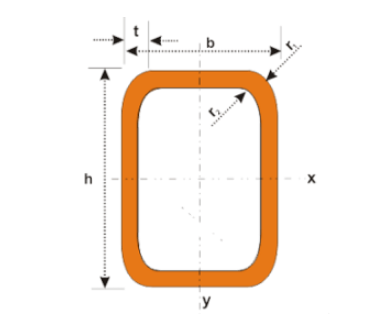

RHS – Rectangular hollow profiles: economy and strength

Rectangular hollow sections (RHS) also called

rectangular tubes are a popular choice for mechanical, structural and architectural applications. This is due to the fact that the flat surface results in a more economical structural solution for joining and various other types of fabrication work. Due to the rectangular shape of this type of hollow profile, the profile only needs to be straight cut when connecting to other flat surfaces. RHS requires minimal welding or joining edge preparation. RHS can also be used for architectural aesthetics due to its clean lines and structural strength.

RHS steel usage

RHS steel, also known as rectangular hollow structural profiles, are commonly used as standard steel frames and can be loaded from different directions in building structural applications. The uses for RHS steel are endless, as its smooth, flat surface makes construction easier.

Other uses for RHS steel include the construction of residential, industrial, agricultural or commercial structures. These include fence posts, rails, floor bearings, decks, bridges, buildings, houses and countless other construction options. RHS steel is very popular in construction and other manufacturing applications such as automotive and storage due to its strength, affordability and simplicity of use compared to other variants. Its smooth and flat surface makes construction easier.

Since minimal edge preparation is required when joining parts, and ease of joining to other parts, only straight cuts are required before welding to another flat surface. In industrial settings, they are priced based on their strength and ability to withstand heat, pressure and damaging elements.

RHS steel is available in a variety of sizes to suit the required needs and can be cut to exact specifications. They are sometimes favored in structures with exposed structural supports due to their aesthetic value, with their clean lines and flat surfaces considered pleasing to the eye compared to other shapes such as round or square variations.

They can also come in a variety of colors and finishes to enhance their aesthetic qualities and sometimes make them less susceptible to environmental factors. It has a high strength-to-weight ratio, is more cost-effective, and can be recycled and used for a variety of other uses. RHS steel has many different uses and applications due to its versatility and strength.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.