Inspection standard of flange

Contents of flange inspection standard

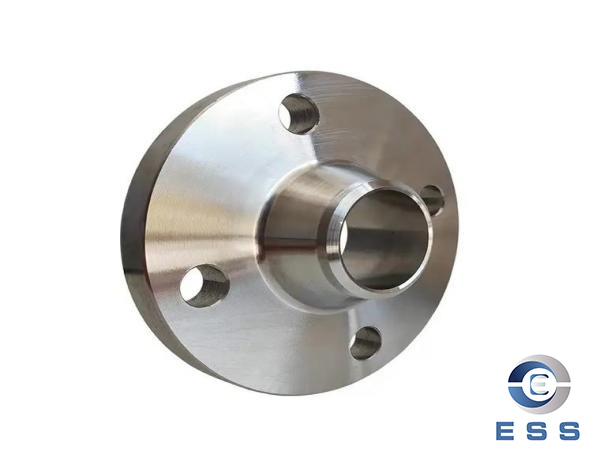

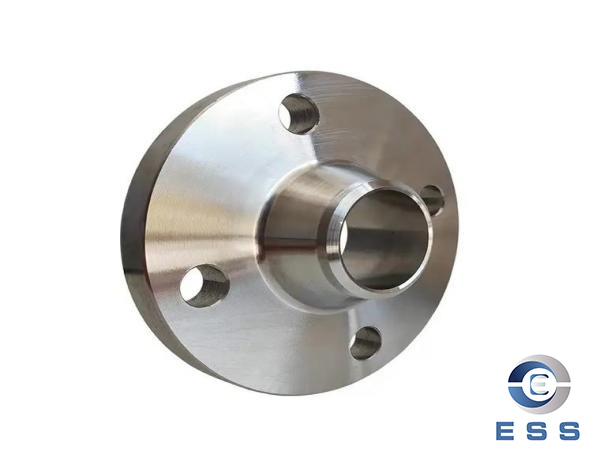

Flange is a common component for connecting pipelines, and it needs to be inspected in use to ensure its safety and reliability. Flange inspection standards mainly include the following contents:

1.Appearance inspection: Check the surface, aperture and wall thickness of the flange to ensure that its shape and size meet the requirements, the flange material should meet the requirements of relevant standards, and should have the corresponding factory inspection certificate, and the flange processing quality should meet the requirements of this technical condition; After the flange is processed, the sealing surface should be coated with antirust oil to prevent scratches and impacts.

(1) The forging surface should be smooth. No forging scars, cracks and other defects are allowed.

(2) Sticky sand and oxide scale on the forging surface should be removed, and defects (such as cracks, shrinkage cavities, slag inclusion, etc.) that affect the service performance of the casting are not allowed.

(3) The machined surface shall be free of burrs, harmful scratches and other defects that reduce the flange strength and connection reliability.

(4) The sealing of the flange on the ring connection surface shall be checked one by one, and there shall be no surface defects such as cracks, scratches and bumps caused by machining on both sides of the groove.

2. Internal inspection: check the corrosion, cracks, holes and other defects inside the flange, and eliminate potential safety hazards in use.

3. Sealing inspection: check the sealing performance of the flange, whether there is leakage, and ensure that the sealing performance of the pup joint meets the standard requirements.

There are two kinds of flanges: rectangular flange and circular flange. According to the different materials used to make flanges, flanges can be divided into ribbed flanges, cored manholes and aluminum profile flanges. Rectangular metal flange Processing Rectangular flange is composed of four profiles. It needs to be completed by drawing lines, cutting, drilling rivet holes, pressing into holes at normal pressure, leveling and aligning, drilling bolt holes and other processing procedures. Straighten the profiles before drawing lines. When drawing lines, it should be noted that the inner dimension of the welded flange should not be smaller than the outer dimension of the air duct, and the allowable deviation value should be reached.

Requirements of flange inspection standard

During flange inspection, the following requirements should be noted:

1. Operators need to have relevant professional knowledge and skills, and be familiar with the structure, use requirements and characteristics of flanges.

2. Appropriate tools and equipment shall be used during inspection to ensure the accuracy of inspection results.

3. Before the inspection, the flange needs to be cleaned and derusted to ensure the accuracy and effectiveness of the inspection. The NDT inspection of the flange is determined by the user and the flange supplier through consultation. The acceptance rules of flanges shall be determined through consultation between users and flange supplier.

4. The inspection results need to be recorded and fed back in time, and corresponding treatment measures need to be taken for the problems found.

5. The flange inspection needs to be carried out regularly to ensure the safety and reliability of the joint.

How to avoid problems in flange use

In addition to regular flange inspection, you can also pay attention to the following aspects to avoid problems in use:

1. Select flange products with reliable quality to avoid quality problems in use.

2. Comply with the use requirements of flanges, and do not overload or mix them randomly to avoid potential safety hazards.

3. Replace the aged or damaged flange parts in time to avoid problems such as leakage in use.

Conclusion

This paper introduces the contents and requirements of flange inspection standards, and how to avoid problems in flange use. For those who use flanges, knowing this knowledge can help them use flanges better and reduce the possibility of problems.

Because different industries have different requirements for flanges, it is necessary to carry out reasonable inspection to ensure the quality requirements of flanges and pay attention to relevant precautions to meet people's needs in production.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.