How Square Tube is Revolutionizing the Automotive Industry

The automotive industry is no stranger to innovation and technological advancements. Over the years, various components and materials have played a crucial role in shaping the industry's evolution. One such innovation that has gained significant attention is the square tube. Originally used in construction and structural engineering, square tubes have found their way into the automotive sector, revolutionizing the way vehicles are designed and manufactured. This article explores how square tubes are transforming the automotive industry, their advantages, applications, and their potential to redefine vehicle performance, safety, and sustainability.

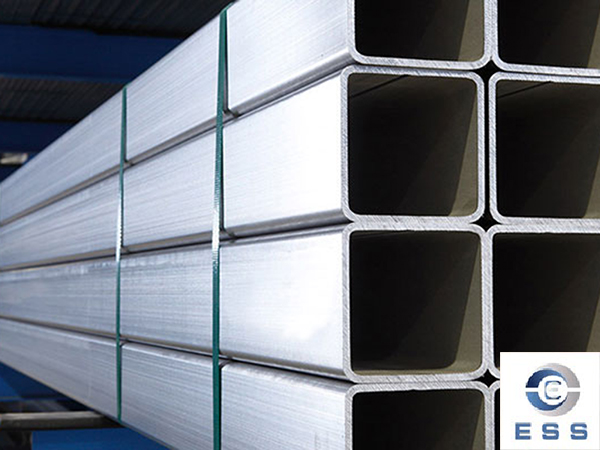

1.Understanding Square Tubes and their Composition

Square tubes are hollow, four-sided structures with equal width, height, and thickness. They are typically made of various materials, including steel, aluminum, and composite materials. The square shape provides exceptional structural stability, making them suitable for numerous applications that require strength and durability. In the automotive industry, square tubes are primarily used for chassis and frame construction, offering enhanced stability and rigidity compared to traditional round tubes.

2.Advantages of Square Tubes in the Automotive Industry

2.1. Strength and Rigidity

One of the key advantages of square tubes over other structural components is their exceptional strength and rigidity. The square shape distributes stress evenly, preventing deformation and improving the overall structural integrity of the vehicle. This enhanced strength allows automakers to reduce weight and material usage without compromising safety.

2.2. Improved Crashworthiness

Square tubes play a vital role in enhancing the crashworthiness of vehicles. The rigid structure of square tubes absorbs and distributes impact energy efficiently, minimizing the transfer of force to the vehicle occupants. By incorporating square tubes into key areas such as the chassis and door frames, automakers can improve passenger safety in the event of a collision.

2.3. Design Flexibility and Integration

The square shape of the tubes allows for better integration into vehicle designs. Square tubes can be easily joined, welded, or bolted together, facilitating efficient assembly processes. Additionally, the flat surfaces of square tubes provide ample space for mounting brackets, components, and accessories, allowing for greater design flexibility and optimizing the use of available space.

3.Applications of Square Tubes in the Automotive Industry

3.1. Chassis and Frame Construction

The chassis and frame of a vehicle are crucial for maintaining structural integrity and supporting the weight of the entire vehicle. Square tubes, with their superior strength and rigidity, have become increasingly popular for chassis and frame construction. They offer excellent torsional stiffness, minimizing flexing and ensuring precise handling and stability.

3.2. Impact Absorption Structures

Incorporating square tubes into impact absorption structures such as crumple zones can significantly improve vehicle safety during collisions. Square tubes efficiently absorb and distribute impact energy, reducing the risk of severe damage to the passenger compartment and protecting occupants.

3.3. Battery Enclosures for Electric Vehicles

As the demand for electric vehicles (EVs) continues to rise, the automotive industry faces the challenge of designing safe and efficient battery enclosures. Square tubes, with their strength and rigidity, are ideal for constructing battery enclosures that provide protection from external impacts and ensure the safety of the vehicle's high-voltage components.

3.4. Suspension Components

Square tubes can also be utilized in the design of suspension components, such as control arms. The enhanced strength and rigidity of square tubes contribute to improved handling and responsiveness, providing a more enjoyable driving experience.

4.Square Tubes and Vehicle Sustainability

Sustainability has become a driving force in the automotive industry, and square tubes offer several environmental benefits. By utilizing square tubes, automakers can reduce the weight of vehicles, resulting in improved fuel efficiency and reduced emissions. Furthermore, square tubes are recyclable, making them an eco-friendly choice for the automotive sector.

5.Challenges and Future Prospects

Despite their numerous advantages, square tubes also pose challenges to the automotive industry. The complex manufacturing processes involved in shaping square tubes can increase production costs. Additionally, the design integration of square tubes requires careful consideration to optimize weight savings without compromising safety.

Looking ahead, advancements in material science and manufacturing techniques may address these challenges. Further research and development could lead to new composite materials specifically tailored for square tubes, offering even greater weight reduction and strength. Additionally, advancements in automated manufacturing processes could streamline production and reduce costs.

Conclusion

Square tubes have emerged as a game-changing innovation in the automotive industry, revolutionizing vehicle design, performance, and safety. With their superior strength, rigidity, and crashworthiness, square tubes offer automakers new possibilities for building lighter, more efficient, and safer vehicles. As the industry continues to embrace sustainability, square tubes provide an eco-friendly solution by reducing weight and improving fuel efficiency. While challenges remain, the future prospects for square tubes in the automotive industry look promising, setting the stage for further innovation and advancements in vehicle technology.

Read more: What does SHS mean in steel terms? or What is the difference between square tube and rectangular tube?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.