How to Choose the Right Size and Length for Your Rectangular Tube

Introduction

Rectangular tubes are a versatile and widely used structural component in various industries such as construction, manufacturing, and engineering. When it comes to choosing the right size and length for your rectangular tube, there are several factors to consider. This article aims to provide you with a comprehensive guide on selecting the appropriate dimensions for your specific application.

Understanding Rectangular Tube Dimensions

Rectangular tubes, also known as rectangular hollow sections (RHS), consist of four sides with rectangular cross-sections. The dimensions of a rectangular tube are typically specified by its height (H), width (W), and wall thickness (T). The length of the tube can vary based on the project requirements.

Analyzing Load Requirements

The first step in selecting the right size and length for your rectangular tube is to analyze the load requirements of your application. Consider the type and magnitude of the load that the tube will bear. This could include static loads (e.g., the weight of a structure) or dynamic loads (e.g., wind or seismic forces). Understanding the load requirements will help determine the necessary strength and rigidity of the rectangular tube.

Structural Considerations

The structural considerations of your project play a crucial role in determining the appropriate size and length of the rectangular tube. Factors such as the span between supports, the anticipated deflection limits, and the desired safety factor should be taken into account. Consulting with a structural engineer or an experienced professional can provide valuable insights into choosing the right dimensions.

Material Selection

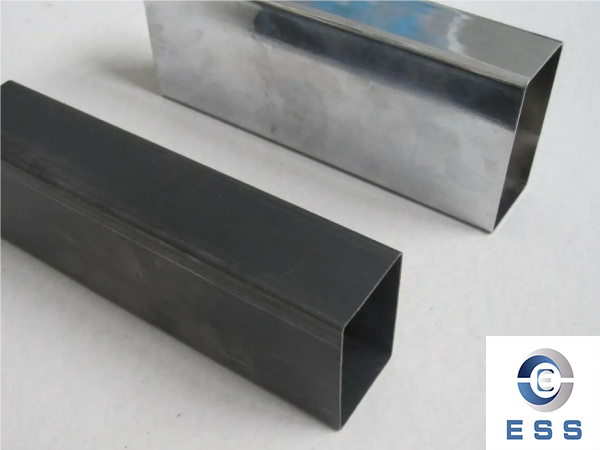

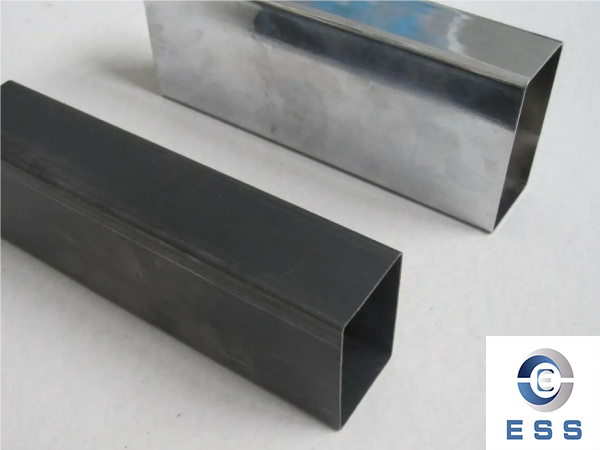

The material used in the manufacturing of rectangular tubes significantly influences their load-bearing capacity and overall performance. Common materials include steel, aluminum, and stainless steel. Each material has its own properties and characteristics, such as strength, weight, corrosion resistance, and cost. Selecting the appropriate material will contribute to the overall structural integrity and longevity of the rectangular tube.

Maximum Allowable Stress

Understanding the maximum allowable stress for the material of your rectangular tube is essential. This refers to the maximum stress the material can withstand before it deforms or fails. The maximum allowable stress is typically provided by material specifications or codes. By considering the maximum allowable stress, you can determine the appropriate wall thickness to ensure structural integrity and safety.

Buckling Considerations

Buckling is a critical failure mode for slender members such as rectangular tubes. It occurs when the compression forces in the tube exceed its capacity, causing it to buckle or collapse. To prevent buckling, the slenderness ratio (L/R) of the rectangular tube must be within acceptable limits. The slenderness ratio is the ratio of the length (L) to the radius of gyration (R). Consulting engineering codes or guidelines will provide guidance on the maximum allowable slenderness ratio for different materials and loading conditions.

Deflection and Stiffness Requirements

The deflection and stiffness requirements of your application will influence the size and length of the rectangular tube. Excessive deflection can affect the overall stability and functionality of a structure, while insufficient stiffness may lead to sagging or bending under load. Understanding the acceptable deflection limits and selecting the appropriate dimensions will ensure the desired performance of the rectangular tube.

Manufacturing Considerations

When selecting the size and length of a rectangular tube, it is crucial to consider the limitations of the manufacturing process. The availability of standard sizes and lengths may impact your options. Additionally, the cost and feasibility of manufacturing customized sizes should be evaluated. Collaborating with a reputable manufacturer or supplier can help you navigate these considerations.

Aesthetic and Design Factors

While the primary focus in selecting the right rectangular tube is its structural suitability, aesthetic and design factors may also come into play. The appearance, finish, and visual appeal of the rectangular tube can be important in architectural and decorative applications. These considerations can influence the choice of material, surface treatment, and dimensions.

Conclusion

Choosing the right size and length for your rectangular tube requires careful consideration of various factors, including load requirements, structural considerations, material selection, maximum allowable stress, buckling considerations, deflection and stiffness requirements, manufacturing limitations, and aesthetic factors. By thoroughly analyzing these aspects and seeking expert advice when necessary, you can ensure that your rectangular tube meets the desired functionality, safety, and performance criteria for your specific application.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.