What is EN10305

EN10305 is a precision seamless

steel pipe material under European standards. This steel tube is widely

used in various industrial fields due to its high precision, excellent

mechanical properties and good processing performance. Steel tubes under

EN10305 standard are usually produced by cold drawing or cold rolling process,

which ensures the dimensional accuracy and surface quality of the product. This

part of EN10305 specifies the delivery technical conditions of precision cold

drawn seamless steel tubes with circular cross-section. The ENI0305 also covers

other types of cross-sections. EN 10305 tubes are characterized by precisely

specified tolerances and specified surface roughness. Typical applications are

in automobiles, equipment and general industrial engineering.

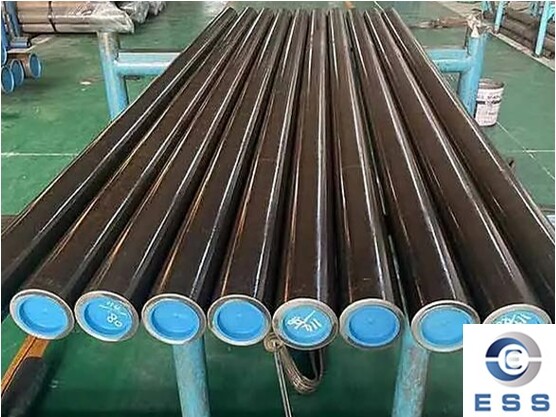

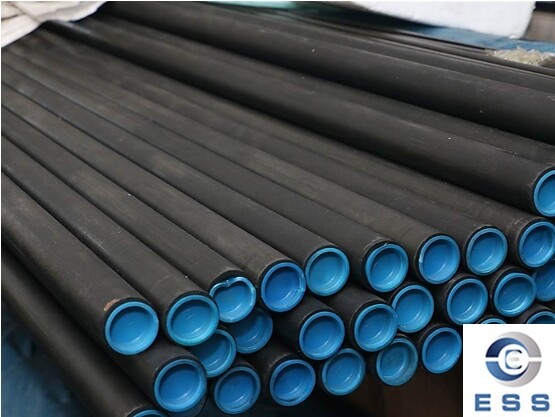

EN10305-4 precision

steel tube

EN10305-4 precision steel tube is a

high-quality seamless steel tube that meets European standards and is mainly

used in hydraulic and pneumatic systems. EN10305-4 precision steel tube

(attribute: cold-drawn precision seamless steel tube) has a series of

remarkable characteristics and performances. The following is a detailed

analysis of its attributes:

Material and process

1. Material

It is often made of high-quality carbon

steel materials such as E235 to ensure the strength and toughness of the steel

tube.

2. Manufacturing process

Cold drawing: The precision and finish of

the precision tube are improved through the cold drawing process.

Non-oxidation bright heat treatment (NBK

state): Ensure that the precision tube has no oxide layer during the

manufacturing process, improve the cleanliness and service life of the steel

tube.

Non-destructive testing: Non-destructive

testing of steel tubes to ensure that the quality of precision tubes meets the

standards.

Specifications and tolerances

1. Specifications

The outer diameter range is wide, ranging

from 4mm to larger sizes, to meet various application requirements.

2. Tolerances

For precision tubes of different outer

diameters, there are clear tolerance regulations to ensure the accuracy and consistency

of the steel tube.

Surface treatment

1. Inner wall treatment

Brushed and flushed with special equipment

to ensure good cleanliness of the inner wall.

2. Outer wall treatment

After anti-rust oil treatment, the steel

pipe is effectively prevented from rusting; the two ends are sealed and

dust-proofed to prevent pollution.

Features

1. Strong ability to withstand high

pressure

Applicable to high-pressure systems to

ensure stable operation of the system.

2. Cold bending without deformation

It has good cold bending performance and

can be used in complex environments.

3. Expanding and flattening without cracks

Various complex deformations and mechanical

processing can be performed to ensure the integrity and reliability of the

steel pipe.

Application field

Widely used in hydraulic systems,

automobile manufacturing, machinery manufacturing, petrochemicals and other

fields, industries with high requirements for precision, finish, cleanliness

and mechanical properties of precision pipes.

1. Hydraulic system

Core pipelines such as hydraulic cylinders, tubings, pump valve connectors.

2. Pneumatic system

Cylinders, air valves, control circuit

pipelines.

3. Automobile manufacturing

Precision pipelines for fuel system, brake

system, and steering system.

4. High-end machinery manufacturing

Textile machinery, printing machinery, hydraulic

piping for injection molding machines, etc.

5. Petrochemical instrumentation

Precision measurement and control

pipelines.

Delivery status

Common delivery statuses include NBK (+N),

GBK (+A), BK (+C), BKW (+LC), and BKS (+SR), etc. Choose the appropriate

delivery status according to specific needs.

1. NBK (+N): Non-oxidizing bright annealing

(most commonly used, high cleanliness, easy processing).

2. GBK (+A): Annealing.

3. BK (+C): Cold working/hardening.

4. BKW (+LC): Light drawing after cold

working.

5. BKS (+SR): Stress relief annealing after

cold working.

Summary

EN10305-4 precision steel tubes have shown

broad application prospects in hydraulic and pneumatic systems and other fields

with their high precision, high strength, high cleanliness and excellent

mechanical properties.

Read more: The difference between precision tube and seamless tube or Difference between seamless pipe and seam pipe

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.