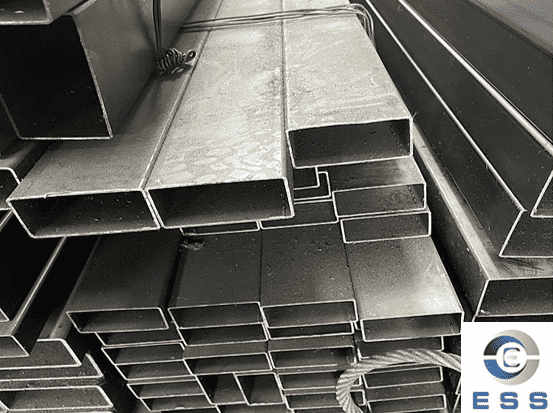

RHS steel (Rectangular tube) is a type of

hollow, long steel tube, also known as flat tube, flat square tube, or

square-flat tube. With the same bending and torsional strength, rectangular

tubes are lighter, making them widely used in the manufacture of mechanical

parts and engineering structures.

ASTM A500 is a standard developed by ASTM

International, covering cold-formed welded and seamless carbon steel structural

tubes.

ASTM A500 rectangular tube specifically

refers to hollow structural steel profiles with rectangular cross-sections

conforming to this standard. ASTM A500 Class B rectangular tubes are the most

commonly used and widely adopted standard rectangular hollow structural steel

profiles in the construction and structural engineering fields in North America

and internationally.

ASTM A500 RHS Steel Advantages

Excellent weldability;

Good machinability;

Cold working capability;

Aesthetically pleasing.

A500 RHS Steel Properties

A500 carbon steel structural tubes are

manufactured using only materials conforming to carbon steel standards. The

chemical composition of A500 is primarily iron, with added carbon, manganese,

phosphorus, sulfur, and copper.

Common Size Ranges for A500 RHS Steel

Long side: 2 inches to 20 inches or longer.

Wall thickness: 0.125 inches to 0.5 inches

or thicker.

A500 RHS Steel Grades and Mechanical

Properties

The ASTM A500 standard includes four

grades: A, B, C, and D. Each grade has different strength requirements.

Grades B and C are the most commonly used

grades for rectangular tubes.

The minimum yield strength for grade B is

46,000 psi.

Grade C has a higher yield strength of

50,000 psi.

These grades ensure that the tubing can

withstand loads, pressure, and resist deformation during use.

The excellent mechanical properties of ASTM

A500 rectangular tubing make it ideal for both static and dynamic structures.

Chemical Requirements of ASTM A500 RHS Steel

|

Element

|

Grades A, B and D

|

Grace C

|

|

|

Heat

Analysis

|

Product

Analysis

|

Heat

Analysis

|

Product

Analysis

|

|

Carbon, max

|

0.26

|

0.30

|

0.23

|

0.27

|

|

Manganese, max

|

...

|

...

|

1.35

|

1.40

|

|

Phosphorus, max

|

0.035

|

0.045

|

0.035

|

0.045

|

|

Sulfur, max

|

0.035

|

0.045

|

0.035

|

0.045

|

|

Copper, when copper steel is

specified, min

|

0.20

|

0.18

|

0.20

|

0.18

|

Tensile Requirements of ASTM A500 RHS Steel

|

|

Grade A

|

Grade B

|

Grade C

|

Grade D

|

|

Tensile strength, mn, ps (MPa)

|

45 000

(310)

|

58 000

(400)

|

62 00

(427)

|

58 000

(400)

|

|

Yield strength, mn, psi (MPa)

|

39 000

(269)

|

46 000

(317)

|

50 000

(345)

|

36 000

(250)

|

|

Elongation in 2 in. (50.8 mm), min, %A

|

25B

|

23C

|

21D

|

23C

|

A500 Outside Dimensional Tolerances for RHS

Steel

There are multiple considerations that must

be accounted for when determining the outside dimensional tolerances for RHS

steel. The chart below and the following attributes describes the exact outside

dimensional tolerances for A500 carbon steel.

|

Outside Large Flat Dimension, in. (mm)

|

Large Flat Dimension Tolerance, A plus

and minus, in. (mm)

|

|

2½ (63.5) or under

|

0.020 (0.51)

|

|

Over 2½ to 3½ (63.5 to 88.9), incl

|

0.025 (0.64)

|

|

Over 3½ to 5½, inc

|

0.030 (0.76)

|

|

Over 5½ (139.7)

|

0.01 times large flat dimension

|

Twist Tolerances for RHS Steel

|

Specified Dimension of Longest Side,

in. (mm)

|

Maximum Twist in the First 3 ft (1 m)

and in each additional 3 ft

|

|

|

in.

|

mm

|

|

1½ (38.1) and under

|

0.050

|

1.39

|

|

Over 1½ to 2½ (38.1 to 63.5),incl

|

0.062

|

1.72

|

|

Over 2½ to 4 (63.5 to 101.6), incl

|

0.075

|

2.09

|

|

Over 4 to 6 (101.6 to 152.4), incl

|

0.087

|

2.42

|

|

Over 6 to 8 (152.4 to 203.2), incl

|

0.100

|

2.78

|

|

Over 8 (203)

|

0.112

|

3.11

|

ASTM A500 vs Other Structural Tubing

Standards

ASTM A500 is often compared to the

following standards:

ASTM A513: Used for mechanical tubing, not

structural tubing.

ASTM A36: Used for structural profiles such

as I-beams, not tubing.

EN

10210: European standard for thermoformed

structural tubing.

In North America, ASTM A500 remains the

preferred standard for welded and seamless structural tubing.

Applications of ASTM A500 RHS Steel

ASTM A500 rectangular tubing is used in

numerous industries due to its high strength, good formability, and wide range

of applications:

1. Construction Industry

It is commonly found in commercial

buildings, warehouses, and residential buildings. Its hollow structure

effectively reduces weight while maintaining structural performance.

2. Infrastructure Projects

RHS steel is used in bridges, road signs,

guardrails, and urban railings. Its reliability under dynamic stress is

critical for safety.

3. Equipment Framing

This tubing is ideal for manufacturing

frames for equipment, agricultural machinery, and transportation systems.

4. Furniture and Design

Modern furniture manufacturers use ASTM

A500 tubing for both aesthetic and practical considerations. Its clean lines

and strength make it ideal for industrial design.

FAQ

1. How strong is RHS steel?

RHS steel is very strong. Due to its unique

shape, rectangular tubing distributes stress evenly when subjected to external

forces, thus improving its overall strength.

Compared to traditional CHS steel,

RHS steel has a more stable cross-sectional shape, effectively resisting

external pressure and bending forces.

2. Is RHS steel stronger than SHS

steel?

RHS steel, due to its rectangular shape, is

generally stronger than square tubes (SHS steel).

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.