Anti-corrosion method of OCTG casing

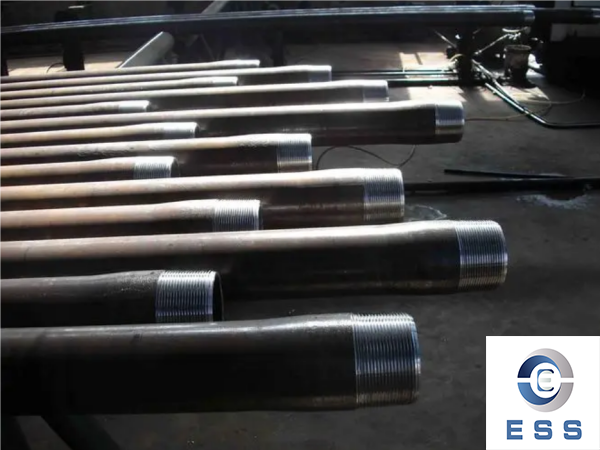

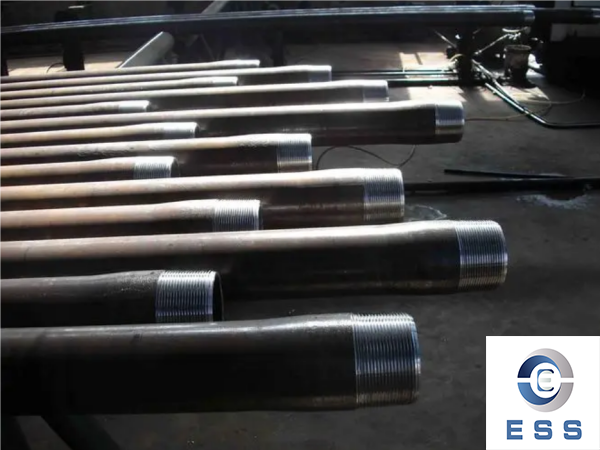

Oil casing is a large-diameter pipe that plays a role in fixing the walls or wellbore of oil and natural gas wells. The casing is inserted into the wellbore and fixed with cement to help the wellbore separate the rock formations and prevent the wellbore from collapsing, while ensuring the circulation of drilling mud to facilitate drilling and mining.

Anti-corrosion countermeasures for oil casing

1. First, ensure that water quality meets standards and strictly monitor and manage water quality. Implement separate cleaning and injection, strengthen the cleaning work of main water pipelines, ensure that the water quality in the station and at the bottom of the well meets the standards, and reduce the introduction of corrosion sources into the annular space;

2. For water injection wells that have been newly put into production, use annular protection fluid mainly for sterilization, and form a system to add it regularly;

3. In view of the acceleration effect of mechanical scratches on the corrosion of oil casing, it is recommended to add a rubber ring to the coupling of the oil pipe or a centralizer to the severe deviation of the well to prevent the oil pipe from scratching the casing and during the water injection process. One side contacts the casing;

4. In view of the severe bacterial corrosion under the scale and the slow growth and killing of SRB at high temperatures, high-temperature water or water vapor of 100 degrees Celsius can be regularly injected into the annulus to kill the SRB under the scale;

5. Before the corrosion in the water injection well casing is effectively controlled, it is not recommended to promote the use of cathodic protection and coated casing.

Packaging and storage

According to the American Petroleum Institute standard APISPEC5CT 1988 1st edition, casing steel grades are H-40, J-55, K-55, N-80, C-75, L-80, C-90, C-95, P- There are 10 types of 110 and Q-125. The casing should be supplied with threads and couplings, or in any of the following pipe end forms: plain end, round thread without or with couplings, trapezoidal thread with or without couplings, direct connection Type thread, special end processing, sealing ring structure.

Origin

(1) The main importing countries of oil casing are: Germany, Japan, Romania, the Czech Republic, Italy, the United Kingdom, Austria, Switzerland, the United States, and Argentina and Singapore also import. Import standards mostly refer to the American Petroleum Institute standards API5A, 5AX, and 5AC. Steel grades are H-40, J-55, N-80, P-110, C-75, C-95, etc. The main specifications are 139.77.72R-2, 177.89.19R-2, 244.58.94R-2, 244.510.03R-2, 244.511.05R-2, etc.

(2) API specifies three lengths: R-1 is 4.88~7.62m, R-2 is 7.62~10.36m, and R-3 is 10.36m or longer.

(3) Some imported goods are marked with LTC, which means long threaded casing.

(4) In addition to API standards, casing imported from Japan also adopts Japanese factory standards (such as Nippon Steel, Sumitomo, Kawasaki, etc.). The steel numbers are NC-55E, NC-80E, NC-L80. NC-80HE etc.

(5) In the claim cases, there have been appearance defects such as black buckles and threaded buckle damage, folding of the pipe body, broken buckles, excessive thread tightness, excessive coupling J value, and internal defects such as casing brittleness and low yield strength. quality problem.

Package

According to SY/T6194-96, domestic casing should be bundled with steel wire or steel belt. A protective ring should be screwed on the exposed portion of each casing and coupling thread to protect the thread.

Read more: What is OCTG Casing? or What are the grades of OCTG casing?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.