The pressure of seamless hydraulic

tubes is usually between 1000 and 8000 pounds per square inch (PSI). The

specific value depends on factors such as pipe specifications, materials, wall

thickness and use environment.

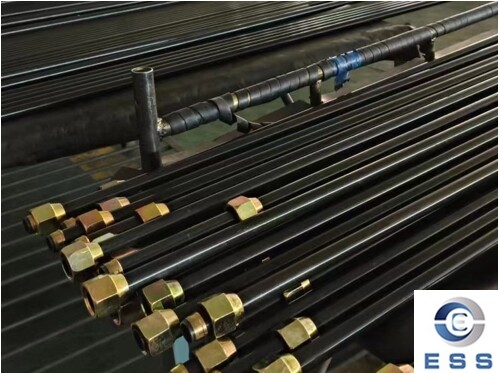

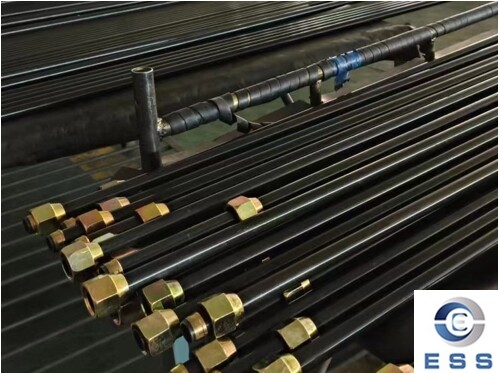

Seamless hydraulic tubes are an

indispensable part of hydraulic systems, and their ability to withstand

pressure directly affects the normal operation and safety of the system. So,

what is the pressure of hydraulic tubes? This is not a fixed value, but the

result of the influence of multiple factors.

Pressure level of hydraulic tubes

Hydraulic tubes used in hydraulic systems

need to withstand high-pressure impacts and precise fluid flow control, so the

material, wall thickness, outer diameter and other parameters of hydraulic

tubes need to be standardized. According to the different pressures of

hydraulic tubes, hydraulic tubes are generally divided into three pressure

levels: light (L), standard (S), and heavy (H).

1. Light hydraulic tubes

Light hydraulic tubes are suitable for

low-pressure hydraulic systems, and their pressure is generally 0-16Mpa.

2. Standard hydraulic tubes

Standard hydraulic tubes are suitable for

medium-pressure hydraulic systems, and their working pressure is generally

16-32Mpa.

3. Heavy-duty hydraulic tubes

Heavy-duty hydraulic tubes are suitable for

higher-pressure hydraulic systems, and their working pressure can be as high as

64Mpa or more.

Factors affecting the pressure-bearing

capacity of hydraulic tubes

1. Pipeline specifications

Seamless hydraulic tubes of different

specifications have differences in their ability to withstand pressure.

Generally speaking, the larger the pipe diameter and the thicker the wall

thickness, the stronger its ability to withstand pressure. The diameter of the

hydraulic tube is proportional to the working pressure, while the pipe length

is inversely proportional to the maximum working pressure and its stress.

2. Material selection

The material

of the seamless hydraulic tube has a decisive effect on its ability to

withstand pressure. Common materials such as carbon steel, stainless steel,

aluminum alloy, etc. each have different strengths and toughness, which affects

the pressure-bearing capacity of the pipe. The pipes and joints in the

hydraulic system also need to withstand instantaneous pressure shocks, so it is

necessary to select corrosion-resistant, wear-resistant, high-strength

water-bath heat-treated seamless

steel pipes.

3. Use environment

The use environment of the seamless

hydraulic tube will also affect its ability to withstand pressure. For example,

factors such as temperature, humidity, corrosive media, and vibration may

affect the pressure bearing capacity of the pipeline to varying degrees.

The operating speed of the hydraulic system

is also an important factor affecting the pressure of the hydraulic tube. If

the speed is too fast, the inertia of the liquid in the pipe will increase the

pressure fluctuation, resulting in pipe rupture.

The range of pressure that the hydraulic

tube can withstand

Taking the above factors into

consideration, the pressure range of seamless hydraulic tubes is usually

between 1000 and 8000 pounds per square inch (PSI). However, this does not mean

that all hydraulic tubes can work safely within this range. In fact, the

specific value needs to be determined based on the actual specifications,

materials, wall thickness, and use environment of the pipe.

How to choose the right hydraulic tube

In order to ensure the normal operation and

safety of the hydraulic system, it is very important to choose the right

hydraulic tube. In the selection process, factors such as pipe specifications,

materials, wall thickness, and use environment should be fully considered, and

choose suitable hydraulic

tubes in different pressure hydraulic systems to ensure that the selected

hydraulic tubes can withstand the working pressure required by the system.

Summary

In short, the pressure that seamless

hydraulic tubes can withstand is not a fixed value, but the result of the

combined influence of multiple factors. Understanding these influencing factors

is of great significance for the correct selection and use of hydraulic tubes,

which helps to ensure the stable operation and safety of the hydraulic system.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.