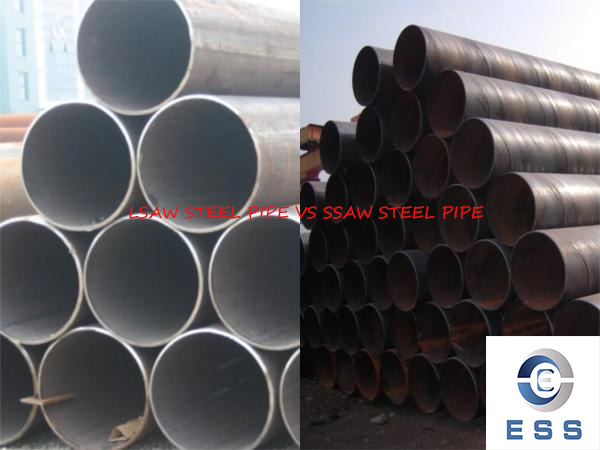

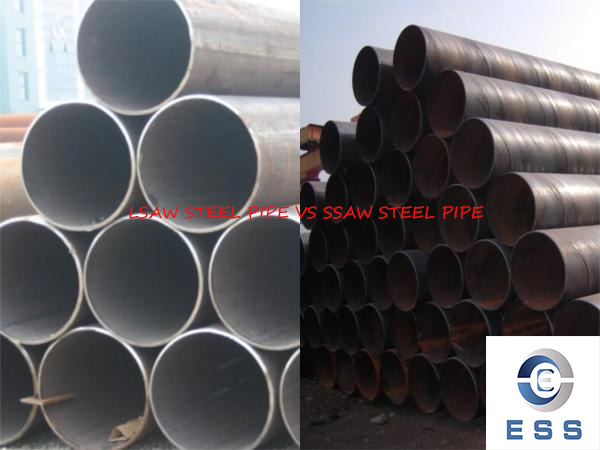

What is the biggest difference between SSAW steel pipe and LSAW steel pipe?

Spiral submerged arc welded pipes and longitudinal submerged arc welded pipes are carbon steel pipes that use submerged arc welding technology. Submerged arc welding is a welding method in which the arc burns under a layer of flux. Its inherent advantages such as stable welding quality, high welding productivity, no arc, and less smoke make it the main welding method in the production of important steel structures such as pressure vessels, pipes, box beams, and columns.

LSAW (straight seam submerged arc welding) is produced by pressing (rolling) a single medium-thick plate in a mold or forming machine and using double-sided submerged arc welding and diameter expansion. The finished product has complete specifications, has good toughness, plasticity, uniformity and density of welds, and has the advantages of large pipe diameter, thick pipe wall, high pressure resistance, low temperature resistance, and strong corrosion resistance. It is widely used in the construction of long-distance oil and gas pipelines with high strength, high toughness and high quality. According to API standards, in large oil and gas pipelines, straight seam submerged arc is the only specified pipe type when passing through Class I and Class II areas such as alpine areas, seabed, and densely populated urban areas.

SSAW steel pipe (spiral submerged arc welded steel pipe) is a pipe rolled in such a way that its forward direction forms a forming angle with the center line of the formed pipe, and is welded while forming. The weld is in a spiral shape. The advantage is that the same specification can produce steel pipes of various diameters. , the raw material has great adaptability, the weld can avoid the main stress, and the stress condition is better. The disadvantage is that the geometric dimensions are poor, the weld length is longer than that of straight seam pipes, and welding defects such as cracks, pores, slag inclusions, and welding deviations are prone to occur, and the welding stress is in a tensile stress state. Generally, the design specifications for long-distance oil and gas pipelines stipulate that spiral submerged arc welding can only be used in Category III and Category IV areas.

Main features

Main features of straight seam submerged arc welded steel pipe:

1) The steel pipe has longitudinal welds, and the internal and external welds are welded by submerged arc welding.

2) After the overall mechanical diameter expansion treatment, the internal stress of the steel pipe is small and evenly distributed, which can effectively prevent stress corrosion cracking, and has high dimensional accuracy, which facilitates on-site welding construction.

3) Using pre-welding and precision welding processes, the welding process is stable and the weld quality is high. Welds are easy to implement non-destructive testing during production and on-site during use.

4) The range of product specifications is large, and it can produce both small diameter and large wall thickness steel pipes and large diameter and large wall thickness steel pipes.

Main features of SSAW steel pipe:

1) Spiral submerged arc welded pipe equipment has low investment, simple production process, low operating cost, and has the advantages of low-cost operation.

2) When used in pressure pipeline projects, especially gas pipelines, there should be necessary hardware configurations, such as non-destructive testing and physical and chemical testing facilities. Quality assurance measures should be strengthened and supervision should be strictly carried out in accordance with the production license.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.