Structural steel is different from ordinary

seamless steel pipes. It is a bar-shaped steel with a certain cross-sectional shape and size. It is one of the four major types of steel (plate, pipe, shape, and wire). According to the shape of the section, section steel is divided into simple section section steel and complex section section steel (special-shaped steel). The former refers to square steel, round steel, flat steel, angle steel, hexagonal steel, etc.; the latter refers to I-beam, channel steel, rail, window frame steel, curved section steel, etc.

Classification of steel

According to the quality of steel smelting, section steel is divided into ordinary section steel and high-quality section steel. Ordinary section steel is divided into large section steel, medium section steel and small section steel according to the current metal product catalogue. Ordinary section steel can be divided into I-beam, channel steel, angle steel, round steel and so on according to its cross-sectional shape.

Large-scale section steel: In large-scale section steel, I-beam, channel steel, angle steel, and flat steel are all hot-rolled, and round steel, square steel, and hexagonal steel are not only hot-rolled, but also forged and cold-drawn.

I-beams, channel steels, and angle steels are widely used in industrial buildings and metal structures, such as factory buildings, bridges, ships, agricultural machinery and vehicle manufacturing, transmission towers, and transportation machinery, and are often used together. Flat steel is used in construction sites as bridges, house frames, fences, power transmission ships, vehicles, etc. Round steel and square steel are used for various mechanical parts, agricultural machinery accessories, tools, etc.

Medium-sized steel: medium-sized steel, trough, angle, round, flat steel, the use is similar to that of large-sized steel.

Small section steel: Angle, round, square, and flat steel in small section steel, the processing and use are similar to large section steel, and small diameter round steel is often used as building reinforcement

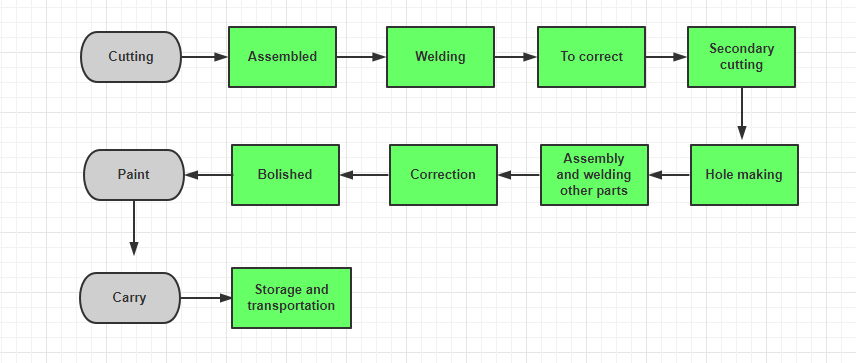

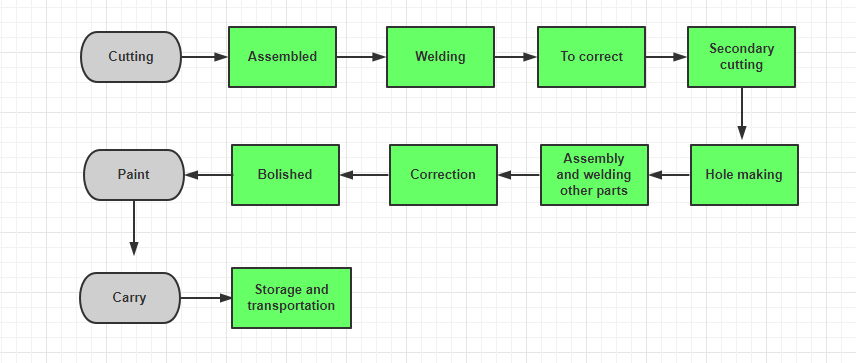

Welded H-beam processing process:

Characteristics of various types of steel

Application characteristics of H-shaped steel

The hot-rolled H-beam reasonably distributes the aspect ratio of the cross-sectional size according to different uses, and has excellent mechanical properties and superior performance.

The design style is flexible and rich. In the case of the same beam height, the bay of the steel structure can be 50% larger than the bay of the concrete structure, so that the building layout is more flexible.

The structure is light in weight. Compared with the self-weight of the concrete structure, it is lighter, and the reduction of the self-weight of the structure reduces the internal force of the structural design, which can make the foundation treatment requirements of the building structure low, the construction is simple, and the cost is reduced.

The steel structure mainly made of hot-rolled H-shaped steel has scientific and reasonable structure, good plasticity and flexibility, and high structural stability. It is suitable for building structures that withstand large vibration and impact loads. Building structures in the earthquake zone. According to statistics, in the world's devastating earthquake disasters of magnitude 7 or above, the steel structure buildings mainly made of H-shaped steel suffered the least damage.

Increase the effective use area of the structure. Compared with the concrete structure, the cross-sectional area of the steel structure column is small, which can increase the effective use area of the building. Depending on the different forms of the building, it can increase the effective use area by 4-6%. Compared with welded H-shaped steel, it can significantly save labor and materials, reduce the consumption of raw materials, energy and labor, low residual stress, and good appearance and surface quality. It is convenient for machining, structural connection and installation, and is also easy to dismantle and reuse.

The use of H-shaped steel can effectively protect the environment, which is reflected in three aspects: first, compared with concrete, dry construction can be used, which produces less noise and less dust; The destruction of land resources is small. In addition, the amount of concrete and rock excavation is greatly reduced, which is conducive to the protection of the ecological environment. Third, after the service life of the building structure expires and the structure is dismantled, the amount of solid waste generated is small, and the recycling value of scrap steel resources is high. .

The steel structure mainly made of hot-rolled H-shaped steel has a high degree of industrialization, which is convenient for mechanical manufacturing, intensive production, high precision, convenient installation, and easy quality assurance. It can be built into a real house manufacturing factory, bridge manufacturing factory, industrial plant manufacturing factory, etc. . The development of steel structures has created and driven the development of hundreds of emerging industries.

The construction speed of the project is fast, the occupied area is small, and it is suitable for all-weather construction, and is less affected by climate conditions. The construction speed of the steel structure made of hot-rolled H-shaped steel is about 2-3 times that of the concrete structure, the capital turnover rate is doubled, and the financial cost is reduced, thereby saving investment. Taking the "Jin Mao Tower" in Pudong, Shanghai, my country as an example, the structural main body with a height of nearly 400 m was completed in less than half a year, while the steel-concrete structure required a two-year construction period.

Application characteristics of angle steel

Angle steel: Commonly known as angle iron, it is a long strip of steel that is perpendicular to each other and forms an angle. There are equilateral angle steel and unequal angle steel. The two side widths of equilateral angle steel are equal, and its specification is expressed in millimeters of side width × side width × side thickness. For example, "∠30×30×3" means an equilateral angle steel with a side width of 30 mm and a side thickness of 3 mm. It can also be indicated by the model number, which is the centimeters of the side width, such as ∠3#. The model does not indicate the size of different side thicknesses in the same model, so fill in the side width and side thickness dimensions of the angle steel in the contract and other documents, and avoid using the model to indicate it alone. The specifications of hot-rolled equilateral angle steel are 2#-20#. Angle steel can be composed of various stress components according to different needs of the structure, and can also be used as a connector between components. Widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves, etc.

Application characteristics of channel steel

Channel steel is a long strip of steel with a groove-shaped cross-section. Its specifications are expressed, such as 120*53*5, which means a channel steel with a waist height of 120 mm, a leg width of 53 mm, and a waist thickness of 5 mm, or 12# channel steel. For channel steel with the same waist height, if there are several different leg widths and waist thicknesses, a b c should be added to the right of the model to distinguish them, such as 25a# 25b# 25c#, etc. Channel steel is divided into ordinary channel steel and light channel steel. The specifications of hot-rolled ordinary channel steel are 5-40#. The specifications of the hot-rolled flexible channel steel supplied by agreement between the supplier and the buyer are 6.5-30#. Channel steel is mainly used in building structures, vehicle manufacturing and other industrial structures, and channel steel is often used in conjunction with I-beams.

Application characteristics of I-beam

I-beam, also known as steel beam, is a long strip of steel with an I-shaped cross section. Its specifications are expressed in millimeters of waist height (h)*leg width (b)*waist thickness (d). 6 mm I-beam. The specifications of the I-beam can also be indicated by the model, and the model indicates the centimeters of the waist height, such as I-16#. For I-beams with the same waist height, if there are several different leg widths and waist thicknesses, you need to add a b c to the right of the model to distinguish them, such as 32a# 32b# 32c#, etc. I-beams are divided into ordinary I-beams and light I-beams, and the specifications of hot-rolled ordinary I-beams are 10-63#. The specifications of hot-rolled ordinary I-beams supplied by agreement between the supplier and the buyer are 12-55#. I-beams are widely used in various building structures, bridges, vehicles, brackets, machinery, etc.

Application characteristics of cold-formed steel

Cold-formed steel is the main material for making light-weight steel structures, and it is made of steel plates or steel strips by cold bending. Its wall thickness can not only be made very thin, but also greatly simplifies the production process and improves production efficiency. It can produce various profiles with uniform wall thickness but complex cross-sectional shapes and cold-formed steel with different materials that are difficult to produce by general hot rolling methods. In addition to being used in various building structures, cold-formed steel is also widely used in vehicle manufacturing, agricultural machinery manufacturing, etc.

Special-shaped steel includes gear ring, horseshoe steel, magnetic pole steel, presser foot plate, shallow channel steel, small channel steel, T-shaped steel, spherical flat steel, cloth feed tooth steel, hot-rolled hexagonal steel, etc. In addition, there are rivet steel, farm tool steel, and window frame steel.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.