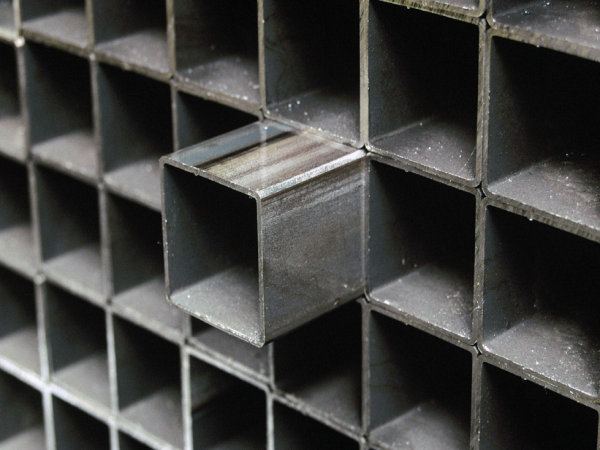

Hollow

structural sections or HSS is a type of metal

profile with a hollow tube section. They are extremely tough and durable. The

most common are circular tubes, square tubes or rectangular tubes, although other shapes are available. It can incorporate a

variety of different alloys in its design. Its versatility makes it useful in a

variety of different industries. RHS steel,

also known as rectangular tube are commonly used as standard steel frames which

can be loaded from different directions in the structural applications of

buildings. RHS Steel uses are endless as its smooth flat surfaces can make

construction easier.

Advantages of RHS Steel

1. High Cost Performance

RHS Steel is very popular in construction

and other manufacturing applications such as automotive and storage due to its

strength, economy and simplicity to use compared to the other variants. Its

smooth flat surfaces can make construction easier.

2. Easy to Connect

Due to the minimal edge preparation

required when connecting sections, and its ease in joining to other sections,

it requires only a straight cut before wielding to another flat surface. In

industrial settings, they are priced for their strength and ability to

withstand high temps, pressure and destructive elements.

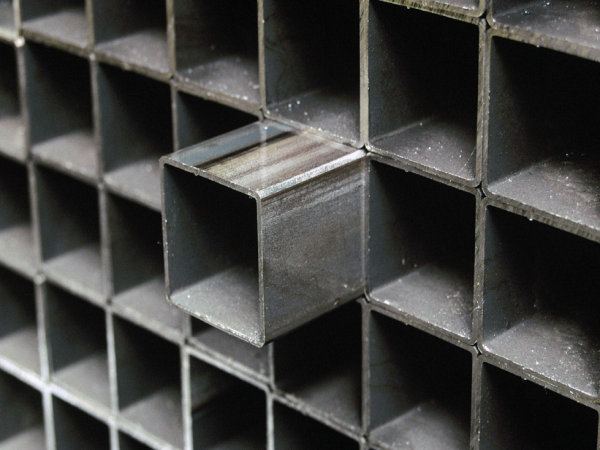

3. Wide Range of Sizes

RHS Steel comes in a broad range of sizes

to suit the required need and can be cut to exact specifications. They are

sometimes preferred in structures with exposed structural supports for their

aesthetic value, its clean lines and flat surfaces are considered pleasing to

the eye compared to the other shapes such as the circular or square variants.

4. Diverse Types

They can also come in a wide variety of

colors and finishes to enhance their aesthetic quality and are sometimes less

susceptible to environmental factors. It has a high strength to weight ratio,

can be more cost effective and is able to be recycled and used for a variety of

other roles. RHS Steel has many different uses and applications due to its

versatility and strength.

Applications of RHS Steel

Uses of RHS Steel is in the construction of

residential, industrial, agricultural or commercial structures. These include

fence posts, rails, bearings for flooring, decking, bridges, buildings, houses

and a myriad of other construction options.

1. Applications of RHS Steel in the

Construction Industry

In the construction industry, RHS steel is

primarily used in the support structures of large structures, such as bridges.

Its excellent load-bearing capacity,

stability, and ease of processing make it widely used in the construction of

high-rise buildings and long-span bridges.

2. Applications of RHS Steel in the

Machinery Manufacturing Industry

In the manufacturing of mechanical

equipment, RHS steel is ideally suited to the demands of high precision and

high rigidity.

For example, in the manufacture of

components such as machine tool bed frames, its precise dimensions and

excellent straightness ensure the stability and precision required by the

equipment.

3. Applications of RHS Steel in the

Automotive Industry

RHS steel also plays a vital role in

automotive engineering.

For example, a combination of rectangular

and round tubes is used in key areas such as vehicle body reinforcements and

frames to achieve vehicle body safety and comfort design goals.

4. Overview of Other Applications

In addition to the aforementioned

industries, RHS steel also has a wide range of applications in the manufacture

of aircraft components and other specialized applications, such as the

shipbuilding industry.

In these applications, special-sized

rectangular hollow sections made of high-strength materials are often selected

to meet the challenges posed by unique operating environments and usage

conditions.

Selection Considerations

When selecting RHS steel, it's important to

comprehensively consider the operating environment, load requirements, and

budget.

For example, stainless steel or galvanized

rectangular tubes should be preferred for outdoor or humid environments to

prevent rust.

For structures bearing heavy loads,

sufficient wall thickness is required.

A comprehensive range of specifications

doesn't mean blind selection; rather, it's important to tailor your selection

to meet your specific needs and avoid overspending. When purchasing, it's

recommended to provide suppliers with detailed specifications for more accurate

product recommendations.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.