The smls pipe is made by perforating the whole round steel, and the steel pipe without weld seam on the surface is called smls pipe. According to the production method, smls pipes can be divided into hot-rolled smls pipes, cold-rolled smls pipes, cold-drawn smls pipes, extruded smls pipes, and pipe jacking. According to the cross-sectional shape, seamless steel tubes are divided into two types: round and special-shaped, and special-shaped tubes have various complex shapes such as square, oval, triangular, hexagonal, melon-shaped, star-shaped, and finned tubes. The maximum diameter is up to 900mm and the minimum diameter is 4mm. According to different uses, there are thick-walled smls pipes and thin-walled smls pipes. smls pipes are mainly used as petroleum geological drilling pipes, cracking pipes for petrochemical industry, boiler pipes, bearing pipes, and high-precision structural steel pipes for automobiles, tractors, and aviation.

Classification of smls pipes

A steel pipe that is seamless along the perimeter of its cross-section. According to different production methods, it is divided into hot-rolled pipe, cold-rolled pipe, cold-drawn pipe, extruded pipe, pipe jacking, etc., all of which have their own process regulations.

The materials include ordinary and high-quality carbon structural steel (Q215-A~Q275-A and No. 10~50 steel), low alloy steel (09MnV, 16Mn, etc.), alloy steel, stainless acid-resistant steel, etc.

According to the purpose, it is divided into two categories: general purpose (for water, gas pipelines and structural parts, mechanical parts) and special purpose (for boilers, geological exploration, bearings, acid resistance, etc.).

Smls pipes are widely used

1. General-purpose smls pipes are rolled from ordinary carbon structural steel, low-alloy structural steel or alloy structural steel, with the largest output, and are mainly used as pipes or structural parts for conveying fluids.

2. According to different purposes, there are three types of supply:

a. Supply according to chemical composition and mechanical properties;

b. Supply according to mechanical properties;

c. Supply according to hydraulic test. Steel pipes supplied by Types a and b, if used to withstand liquid pressure, are also subject to hydrostatic testing.

3. There are many kinds of seamless pipes for special purposes, such as seamless pipes for boilers, seamless pipes for chemical power, smls pipes for geological use and seamless pipes for petroleum.

Smls pipes have a hollow cross-section and are widely used as pipes for transporting fluids, such as pipes for transporting oil, natural gas, gas, water, and certain solid materials. Compared with solid steel such as round steel, the steel pipe is lighter in weight when the bending and torsional strength is the same, and it is an economical section steel.

Widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile drive shafts, bicycle frames, and steel scaffolds used in construction, etc. Steel pipes are used to make ring parts, which can improve material utilization, simplify manufacturing processes, and save materials and processing Man-hours have been widely used to manufacture steel pipes.

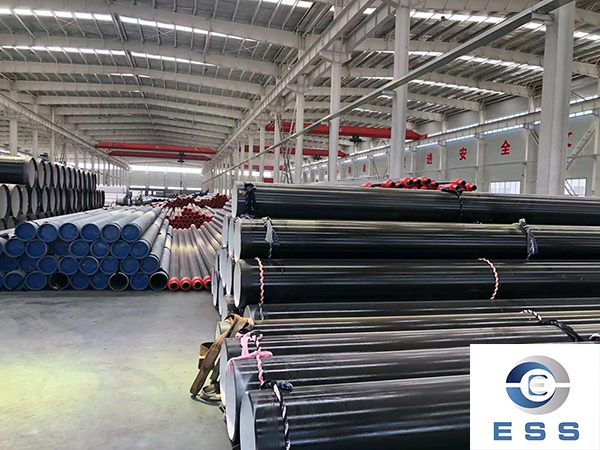

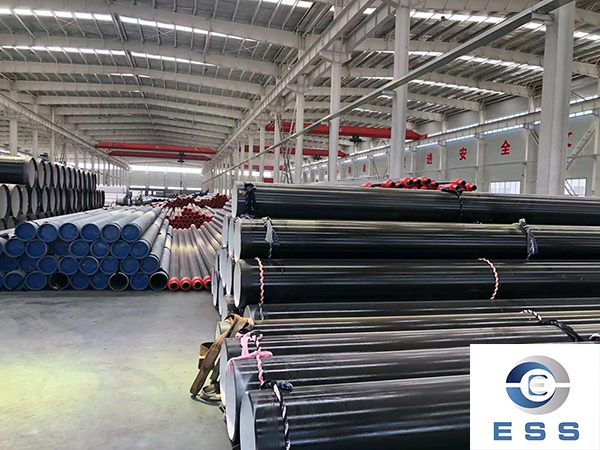

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.