Heat exchange tube

The heat exchange tube is one of the elements of the heat exchanger, which is placed in the cylinder and used for heat exchange between the two media. Has high thermal conductivity and good isothermal properties. It is a device that can quickly transfer heat energy from one point to another with almost no heat loss, so it is called a heat transfer superconductor, and its thermal conductivity is thousands of times that of copper.

Form

In addition to plain tubes, heat exchangers can also use a variety of enhanced heat transfer tubes, such as finned tubes, threaded tubes, spiral grooved tubes, etc. When the heat transfer coefficient on both sides of the inner diameter of the tube has a large difference, the fins of the finned tube should be arranged on the side with the lower heat transfer coefficient.

Size

The commonly used dimensions of heat exchange tubes (outer diameter x wall thickness) are mainly Φ19mmx2mm, Φ25mmx2.5mm and Φ38mmx2.5mm seamless steel pipes and Φ25mmx2mm and Φ38mmx2.5mm stainless steel pipes. Standard pipe lengths are 1.5, 2.0, 3.0, 4.5, 6.0, 9.0m, etc. The use of small pipe diameter can increase the heat transfer area per unit volume, the structure is compact, the metal consumption is reduced, and the heat transfer coefficient is improved. It is estimated that by changing the heat exchange tube of the same diameter heat exchanger from Φ25mm to Φ19mm, the heat transfer area can be increased by about 40%, and the metal can be saved by more than 20%. However, the small diameter of the pipe has large fluid resistance, which is inconvenient to clean and easy to scale and block. Generally, large diameter pipes are used for viscous or dirty fluids, and small diameter pipes are used for cleaner fluids.

Material

Commonly used materials are carbon steel, low alloy steel, stainless steel, copper, copper-nickel alloy, aluminum alloy, titanium, etc. In addition, there are some non-metallic materials, such as graphite, ceramics, polytetrafluoroethylene, etc. In the design, appropriate materials should be selected according to the working pressure, temperature and corrosiveness of the medium.

Center distance

The arrangement of heat exchange tubes on the tube sheet mainly includes equilateral triangle, square and corner equilateral triangle and corner square. The equilateral triangle arrangement can arrange the maximum number of tubes on the same tube sheet area, so it is most commonly used, but it is not easy to clean the outside of the tube. To facilitate cleaning outside the tubes, tube bundles in a square or corner square arrangement can be used. The center distance of the heat exchange tube should ensure that the tube bridge (clearance distance between two adjacent tubes) has sufficient strength and width when the tube is connected to the tube sheet. When cleaning is required between the tubes, a channel for cleaning should also be reserved. The center distance of the heat exchange tubes should not be less than 1.25 times the outer diameter of the heat exchange tubes. The most commonly used center distances of the heat exchange tubes are as follows. Commonly used heat exchange tube center distance (mm).

|

outer diameter

|

10

|

12

|

14

|

16

|

19

|

20

|

25

|

32

|

35

|

38

|

45

|

50

|

57

|

|

center distance

|

13~14

|

16

|

19

|

22

|

25

|

26

|

32

|

40

|

44

|

48

|

57

|

64

|

72

|

How to determine the central moment of the heat exchange tube?

The central moment of the heat exchange tube is generally not less than 1.25 times the outer diameter of the heat exchange tube, which is mainly considered:During expansion, the elastic deformation ranges between the pipe holes do not intersect; when welding, leave a certain distance between the welds of each pipe section to reduce the welding stress between them. For slot welding around the tube hole on the tube sheet, the central moment of 125% of the outer diameter of the heat exchange tube is already the lower limit, and more than 132% of the outer diameter of the tube can be taken when conditions permit; this value is greater than or equal to 25mm. For heat pipes, it is convenient enough to clean the tube bundle, but for heat exchange tubes with an outer diameter of less than 25mm, in order to facilitate cleaning, the clear distance between the tubes should be 6mm.

Why can the heat exchange tube not consider the corrosion allowance?

The corrosion of the heat exchange tube definitely exists, but it is mainly concentrated in the pipe joints, and uniform corrosion is generally not the main problem; the heat exchange tube is a heat exchange element, if it is too thick, it will affect the heat exchange efficiency; the diameter of the heat exchange tube is very large. If it is small, the corresponding calculated thickness is also small, and the corrosion allowance is still there, but it is not as large as the shell, so its design service life is shorter than that of the shell; if the corrosion is serious, corrosion-resistant materials can be used. For example, some heat exchanger tubes are made of stainless steel, while the shells and heads of the shell side and tube side are all carbon steel; if the heat exchange tubes are corroded and penetrated, they can be replaced; The way to solve it, insist on using it until the next overhaul in order to replace the new heat exchanger.

What are the special requirements for heat exchange tubes?

The heat exchange tube is a pressure component. In addition to the material properties that it should have as a pressure component, the heat exchange tube itself has its own special requirements: high dimensional accuracy (outer diameter, wall thickness, length); material plasticity and toughness Good, especially for tube expansion, flanging and bending; welding performance of thin-walled tubes; low hardness value, generally lower than the hardness value of tube sheet; high test pressure.

What are the requirements for the number of multi-tube heat exchange tubes?

The number of tubes in each process of the multi-tube process should be as equal as possible, and the relative error should be controlled within 10%, and the maximum should not exceed 20%.

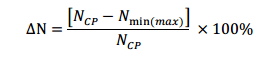

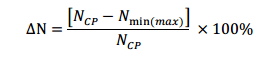

The relative error is calculated as follows:

NCP : Average tube bundles for each tube pass

Nmin(max) : Minimum (maximum) number of tubes for each scale

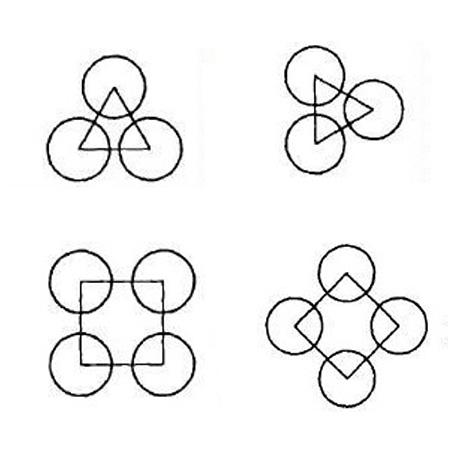

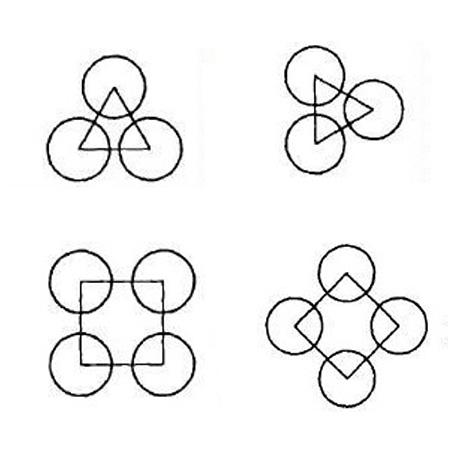

What are the arrangements of heat exchange tubes?

There are four standard arrangements of heat exchange tubes: equilateral triangle, corner equilateral triangle, square, and corner square. Its arrangement is related to the flow direction of the fluid and the direction of the baffle notch. The direction of fluid flow is perpendicular to the notch of the baffle.To convert between equilateral triangles and corner equilateral triangles, it is necessary to rotate the piping by 90". If the tube is rotated 90", the arrangement of the heat exchange tubes is an equilateral triangle arrangement; if the tube is rotated 90", the arrangement of the heat exchange tubes is an equilateral triangle. To convert between square and corner square, you need to rotate the pipe by 45" (note that 45" is not 90" here). If the tube is rotated 90", the arrangement of the heat exchange tubes is still a square, and if the tube is rotated 45", the arrangement of the heat exchange tubes is a corner square; if the tube is rotated 90", the arrangement of the heat exchange tubes is still The corners are square, and if the pipe is rotated 45", the heat exchange tubes are arranged in a square form.

Read more : The reason why heat exchanger tubes are mostly round instead of square

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.