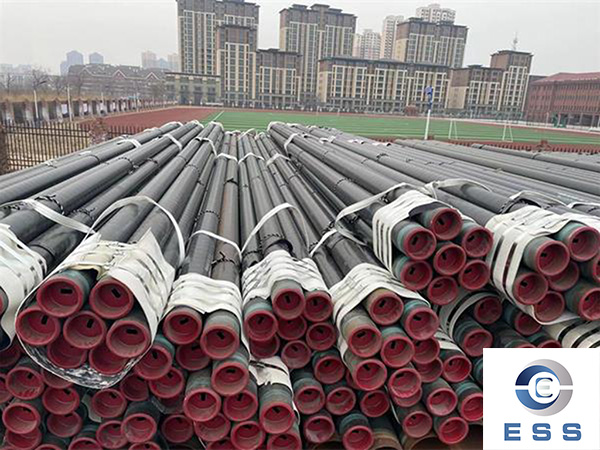

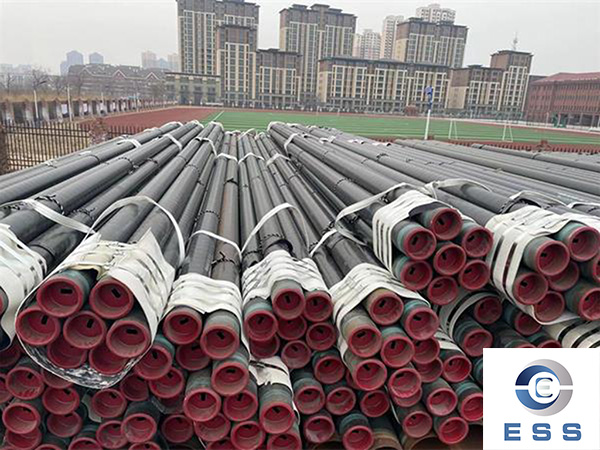

Seamless tubes are made from solid round steel "bills" that are heated and pushed and pulled over a die until the steel is formed into a hollow tube.Seamless tubes undergo various finishing operations such as straightening, inspection, hydrostatic testing and imaging. Seamless pipes are widely used in pressure piping, construction, petrochemical and oil refineries. Seamless pipe is available in the following specifications: ASTM A53, A106, A252, A333, A335, A501, A523, A589, API 5L and API 5CT. The most common seamless pipe is A106B.End finishes for seamless pipe include beveled or square-cut flat ends. Seamless carbon steel pipes are available in black, bare, galvanized or epoxy coated.

Steel pipes are typically supplied in lengths of 21 feet. It is also available in Single Random Lengths (SRLs) ranging from 17 feet to 24 feet. Double Random Length (DRL) refers to pipe that is at least 37 feet long to 44 feet long.

Seamless pipe weight calculation formula

The weight of seamless steel pipe per meter is W=0.02466*S(D-S).

Symbol meaning: D=outer diameter, S=wall thickness.

For example, for seamless steel pipes with an outer diameter of 60mm and a wall thickness of 4mm, find the weight per meter.

Solution: Weight per square meter=0.02466*4*(60-4)=5.52Kg.

The theoretical weight calculation formula of seamless steel pipe is W=0.0246615(D-S)*SW.

seamless vs welded pipe

Seamless steel pipes are made of round billets by hot rolling, cold rolling or cold drawing, and the pipe body has no joints. Welded steel pipes are manufactured from flat steel plates with welds on the pipe body. Including ERW tube, LSAW tube, SSAW tube. The difference between seamless pipe and welded pipe in raw materials, manufacturing process, performance, appearance, size, application, cost price, etc.

Seamless steel pipe:

API 5L and ASTM seamless steel pipes are made from steel ingots or solid tubes, passed through perforated tubes, which can then be formed by hot rolling, cold rolling or cold drawing. Hot-rolled seamless steel pipes are made by billet forging, piercing, rolling, shaping and other processes. For large diameter pipes, thick-walled seamless pipes usually adopt this method. Cold-drawn seamless pipe adopts cold-drawn forming technology. The material strength is relatively low, and the exterior and interior control surfaces are smooth. Small-diameter thin-walled seamless pipes are usually made by this method. Seamless steel pipes are rolled from carbon structural steel, low alloy structural steel or alloy structural steel and stainless steel. Seamless steel pipes are used in different industries: line pipes in pipelines, thermal services, machinery industry, chemical industry and other industries.

Welded steel pipe:

API 5L or ASTM welded steel pipe includes LSAW pipe, SSAW pipe and ERW pipe. These pipes are made of steel strip or steel plate. The manufacturing process first bends the steel plate and then welds it into round, square and other shapes. Welded steel pipes have the characteristics of high production efficiency, low cost and material saving. It has been widely used in aviation, aerospace, energy, electronics, automobile, light industry and other industries. Strong corrosion resistance in acidic environments.

Characteristics of seamless steel pipes

The reason why most people prefer seamless steel pipe to welded steel pipe is that seamless steel pipe can withstand extremely high pressures without breaking. But seams or welded pipes can't do this, because the solder joints are prone to cracking under high pressure. In addition, it is very easy to accurately calculate the pressure of seamless pipes. Seamless pipes are also thinner and lighter than welded pipes and have a uniform shape because they are uniformly extruded from the alloy.

Comparison of pressure strength of seamless pipe and welded steel pipe

Seamless steel pipe has better bearing capacity and strength is higher than ERW welded steel pipe. Therefore, it is widely used in high-pressure equipment, thermal power, and boiler industries. Generally, the weld of welded steel pipe is the weak point, and the quality of it affects the overall performance.

Summary of the difference between seamless steel pipe and welded steel pipe

1. Appearance difference

The seamless steel pipe is made of billet as raw material. The outer surface defects of the billet cannot be eliminated by the hot rolling process and can only be polished after the product is finished. In the process of wall reduction, defects can only be partially eliminated. For welded steel pipes made from hot-rolled coils, the surface quality of the coils is the surface quality of the pipes, which is easy to control. The surface quality of hot rolled coil is high. Therefore, the surface quality of welded steel pipe is much better than that of seamless steel pipe.

2. Differences in molding process

Seamless steel pipes are formed in one pass during the rolling process. Welded steel pipes are manufactured from steel strips or steel plates by bending and different welding processes.

3. Performance and use

Seamless steel pipe has better bearing capacity and strength is higher than ERW welded steel pipe. Therefore, it is widely used in high-pressure equipment, thermal power, and boiler industries. Generally, the weld of welded steel pipe is the weak point, and the quality of it affects the overall performance. Generally speaking, the working pressure of welded steel pipe is 20% lower than that of seamless steel pipe. This reliability is the main factor people choose seamless steel pipe. Virtually all industrial piping is seamless, simply because the pipes are subjected to extreme thermal, chemical and mechanical workloads. Aerospace, automotive, electronics and other industries have relatively low budgets, and pipe work pressures are high, and welded pipes are more preferred.

4. Available size difference

For most seamless steel pipe manufacturers in China, they produce original seamless pipes with a maximum outer diameter of 20 inches, 508 mm. Usually less than 16 inches, 406.4 mm due to equipment limitations. If the customer wants to purchase seamless steel pipes exceeding the above dimensions, thermal expansion processing is required. But usually the quality of this heat-expanded seamless steel pipe cannot be compared with the original seamless steel pipe. Conversely, welded steel pipes do not have these limitations and are available in sizes ranging from 1-1/2 inches 48.3 mm to 100 inches 2540 mm.

5. Cost and Price

Usually seamless steel pipes cost more than welded steel pipes because of raw materials, manufacturing equipment and processes. But sometimes due to market pressure, the price of welded pipe is higher, so if this happens, please do not hesitate to buy seamless steel pipe of the same size.

ERW vs seamless pipe

ERW pipe is made by rolling metal and then welding it longitudinally along its length. Seamless pipe is made by extruding metal to the desired length; therefore ERW pipe has a welded joint in its cross section, while seamless pipe does not have any joint in its cross section throughout its length. In a seamless tube, there are no welds or joints, and it is made from a solid round billet. Seamless tube sizes and wall thickness specifications range from 1/8" to 26" OD. Ideal for high pressure applications such as hydrocarbon industry and refineries, oil and gas exploration and drilling, oil and gas transportation as well as air and hydraulic cylinders, bearings, boilers, automotive and more.

ERW pipe is longitudinally welded and manufactured from strip/coil up to 24" outside diameter. ERW tube is cold formed from a strip of steel that is pulled through a series of rollers and forms a tube, which is melted by an electric charge. It is mainly used for low/medium pressure applications such as water/oil transfer.

The difference between the production technology of seamless pipe and erw steel pipe

The "CPE" technology for the production of seamless pipes and tubes with an outside diameter of up to 7 inches is a world-renowned technology. The "Plug Mill" technology is used for high diameters. Seamless steel pipes are produced from 7 inches to 14 inches and are the most reliable technology for larger diameters. part. High frequency induction welding technology for ERW pipe and tubing up to 21" OD.

How to identify seamless or ERW stainless steel pipe?

To determine if the supplied pipe is seamless or ERW, simply read the template on the side of the pipe

If it is ASTM A53, Type S is seamless.

Type F is furnace type but welded,

Type E is resistance welding.

That's how. This is the easiest way to identify if the pipe is seamless or ERW.

Read more :Quality defects and prevention of seamless steel pipe blanks

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.