Boiler tube leakage is one of the most common problems in industrial boiler operation. If not handled promptly, it can easily lead to boiler shutdown, reduced energy efficiency, and even safety accidents. This article will systematically introduce the causes, symptoms, and repair procedure and methods for boiler tube leakage to help you quickly address boiler tube leakage issues.

Causes of boiler tube leaks

1. Aging of pipelines

After the boiler has been used for a long time, the pipelines will age due to corrosion, wear and other reasons, which will cause pipeline leakage.

2. Too high temperature

The boiler temperature is too high, which will also cause the pipeline to loosen and age, resulting in leakage.

3. Installation problems

Poor installation, untightened and loose pipeline connections, etc. may also cause leakage.

4. Pipeline extrusion and deformation

Pipe extrusion or deformation will also cause cracks in the pipeline and leak.

5. Boiler water temperature is too high

The boiler water temperature is too high, which is also one of the reasons for boiler tube leakage. Excessive water temperature will increase the pressure on the pipeline and cause the pipeline to crack.

Boiler tube leaks symptoms

During boiler operation, closely monitoring

the following abnormal phenomena is crucial for timely detection of boiler tube

leaks:

1. Abnormal steam drum water level

The feedwater flow rate is abnormally

higher than the steam flow rate, and a stable water level cannot be maintained.

2. Flue gas temperature and steam

temperature changes

The flue gas temperature near the leak

point will decrease. Simultaneously, the steam temperature at the outlet of the

superheater or reheater on the corresponding side may show abnormal increases

or decreases.

3. Fluctuations in furnace negative

pressure

A sudden increase or drastic change in

furnace negative pressure may be accompanied by a significant increase in

induced draft fan current.

4. Abnormal sounds

A distinct steam jetting sound can be heard

near the leak point.

5. Abnormal instrument indications

The flue gas detector shows increased flue

gas humidity; simultaneously, the carbon content of fly ash may also increase.

6. Visual phenomena

White steam emerges from the inspection

port, manhole, etc. In severe cases, water may drip from the tail flue, and the

exhaust gas temperature continues to drop.

It is important to note that any single

abnormal symptom may not be conclusive evidence, but when multiple of the

above-mentioned symptoms appear simultaneously, it can generally be determined

that the boiler tubes are leaking.

Boiler tube repair procedure

The boiler tube repair procedure is:

1. Immediately stop boiler operation

Upon discovering a leak, immediately shut

down the boiler and cut off the fuel supply to prevent further leaks and

accidents.

2. Cut off water supply

Close the water supply valve to stop

supplying water to the boiler and reduce the leaking pressure.

3. Vent pressure

Open the vent valve on the leaking pipe to

release the pressure inside the boiler and reduce the leaking pressure.

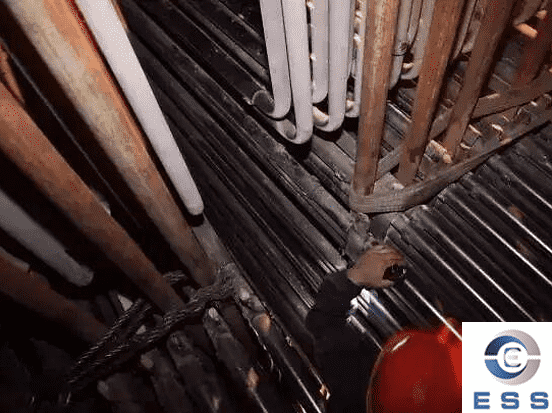

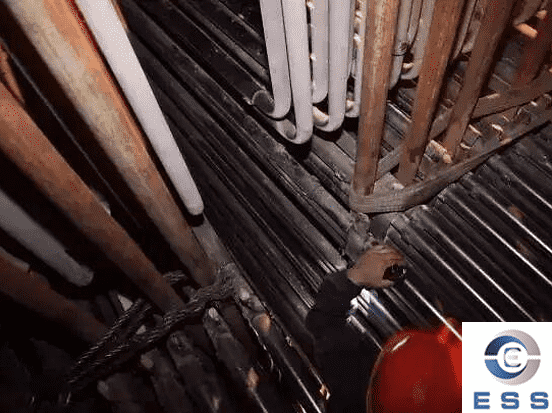

4. Inspect and repair the tube leaks area

Inspect the leaking area for severe damage

or wear. If necessary, replace or repair the fittings at the leaking point.

5. Apply sealant

If the leak is caused by a loose pipe

connection or poor sealing, use an appropriate sealant or lubricant to reseal

it.

6. Perform a pressure test on the pipeline

After repairing the leak, perform a

pressure test to ensure that the boiler tubes are completely repaired and no

longer leaking.

7. Restore water supply and start the

boiler

After confirming that the boiler tubes have

been repaired and there are no leaks, the water supply valve can be reopened to

restore water supply and the boiler can be restarted.

Emergency treatment methods of boiler tube leaks

1. In extreme emergencies, it is necessary to stop the furnace immediately for treatment, and close the water valve and gas valve in time to avoid further leakage accidents.

2. Find the location of the leak: The leak can be found based on the sound of the leak, the bubbling of the pipeline and the connector, so as to better repair it.

3. Use soil or cement to plug the leak: For small leaks, you can use soil or cement to plug the leak and cover it with dry soil to reduce the extent of the leak.

Methods for boiler tube repair

1. Replace the leakage tube

If the leak is serious, it is recommended to replace the leakage tube directly. This method is more thorough and can eradicate the leak problem, but the cost is relatively high.

2. Chemical lap repair

Chemical lap treatment is a relatively simple method, which is suitable for situations where the pipeline leak is relatively small. Use chemical lap materials to fill the leaks in the pipeline so that the leaks do not continue to expand.

3. Welding repair

Welding treatment is a relatively effective method, but you need to pay attention to some details and risks. First, you need to choose the appropriate welding materials and methods. Secondly, you need to pay attention to the temperature and environment around the pipeline to prevent safety accidents such as fire during welding. In addition, when performing welding treatment, you need to follow the specifications and conduct necessary inspections and tests to ensure that the welded pipeline can work normally.

Boiler tube welding treatment skills

When welding boiler tubes, you need to pay attention to the following aspects:

1. Cleaning of tubes

Before welding, you need to clean up the debris around the pipes to ensure that there are no impurities affecting the welding effect during welding.

2. Choose the right welding materials and methods

Choosing the right welding materials and methods can ensure the welding effect. Generally, MIG gas shielded welding or TIG argon arc welding is selected for boiler pipe welding.

3. Protection around the tube during welding

When welding, the area around the pipe needs to be protected from damage. You can use materials such as fire blankets to cover the area around the pipe.

4. Inspection and testing after welding

After welding, the weld needs to be inspected and tested to ensure that there are no cracks and water leakage at the weld of the pipe.

When welding boiler pipes, you need to pay attention to safety and skills. If the technology and conditions do not allow, it is recommended to choose other appropriate treatment methods.

Completely eliminate the cause of the boiler tube leaks

1. Update the pipeline

For aging pipelines, new pipelines need to be replaced to avoid further leakage.

2. Improve installation

For problems such as poor installation, untightened or loose pipe connections, thorough inspection and improvement are required to ensure the normal operation of the pipes.

3. Improve maintenance level

Strengthen daily inspection and maintenance work, timely discover and deal with boiler problems, and avoid escalation of problems.

Precautions

1. Don't be impatient when dealing with boiler tube leaks. Analyze calmly and take corresponding countermeasures.

2. Strictly abide by safety operating procedures to ensure the safety of personnel and equipment.

3. If you cannot judge or deal with the boiler tube leaks problem, you should contact professional technicians in time for treatment.

In short, for the boiler tube leakage problem, we must deal with it in time and take corresponding measures to solve it, avoid further expansion of the leakage problem, and ensure the safety of personnel and equipment.

Summary

In general, boiler tube leakage is not an isolated problem, but rather the result of a combination of long-term operation, improper maintenance, or abnormal operating conditions. When a leak occurs, the cause should be carefully analyzed, and appropriate repair methods should be adopted. If necessary, the boiler tube should be replaced or repaired by professionals to ensure the long-term, safe, and efficient operation of the boiler equipment.

Read more: Boiler Tube Failure Causes and Reduction or Causes and Preventive Measures for Boiler Four-tube Leakage

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.