Check valves and globe

valves have their own characteristics in function and structure, and each

is suitable for different application scenarios. When choosing a valve type,

you should make comprehensive considerations based on actual needs and

application scenarios, communicate and understand in detail with the valve supplier,

and choose the most suitable valve type. So what are the precautions for using

check valves and globe valves? The following will introduce you to common

precautions.

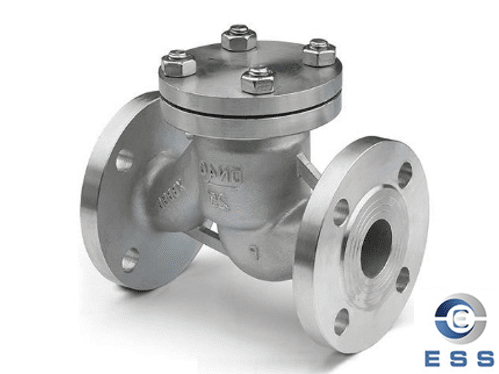

Tips for using check valves

1. Comply with operating procedures: During the operation of the check valve, the operating procedures must be strictly followed to ensure its normal operation. The structure of the check valve must not be adjusted at will to avoid affecting its performance.

2. Regular inspection and maintenance: Check the check valve in detail and maintain it regularly to ensure the normal operation of its parts. For some easily worn parts, such as gaskets, they should be replaced in time to prevent the check valve from failing.

3. Prevent reverse impact: When installing the check valve, ensure that its direction is correct to prevent the medium from being impacted by reverse impact. If the medium may flow in reverse, the corresponding guide device can be installed before and after the check valve to guide the correct flow of the medium.

4. Avoid long-term full-load operation: Try to avoid the check valve from running at full load for a long time to prevent it from overheating and damage. When designing the system, the rated flow and pressure of the check valve should be reasonably calculated to ensure that it operates within a safe range.

5. Pay attention to choosing the appropriate check valve model and material: Choose the appropriate check valve model and material to meet the needs of actual working conditions. When installing the check valve, ensure that it is firmly connected to the pipeline to prevent leakage. If you have any questions or encounter any problems, please contact professionals for technical support.

Tips for using the globe valves

1. Check for leakage: Before opening, check the globe valve in detail for leakage. At the same time, determine whether the valve has leakage problems and whether the stuffing box has leakage problems. Only after confirming that there is no problem can it be opened for operation.

2. Reasonably complete the operation of the globe valve stem: If the globe valve stem cannot be operated manually, a special F wrench can be used instead. If the F wrench still cannot complete the operation of the globe valve stem, the extension wrench cannot be used to force the opening and closing, otherwise it is easy to damage the valve. In serious cases, it may also cause safety accidents.

3. Use of medium-pressure gas pipelines: If the globe valve is used on a medium-pressure gas pipeline, then before opening the globe valve, the condensed water should be removed first, and then the steam on the pipeline should be preheated. The preheating pressure needs to be maintained between 0.2MPa and 0.3MPa, so that the seal can be effectively prevented from being damaged when the temperature or pressure changes.

In general, check valves and globe valves

are different in function and structure, applicable to different use scenarios,

it is very important to pay attention to the details that need to be paid

attention to its use.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.