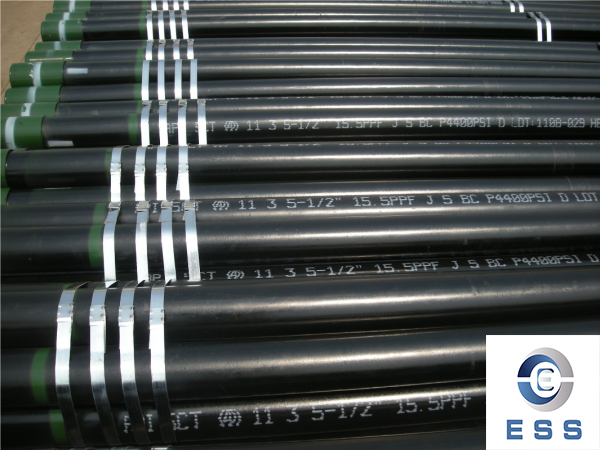

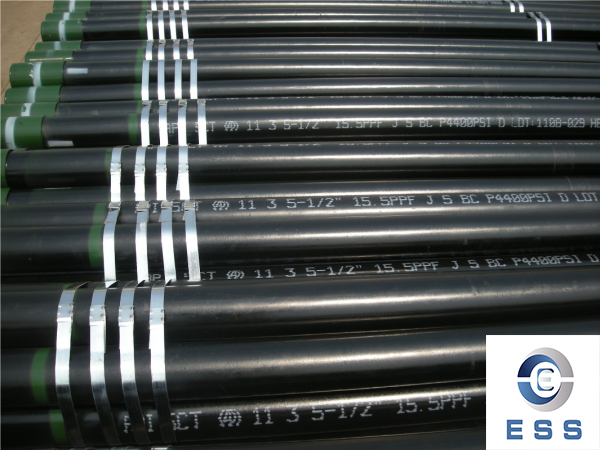

The use and detection of OCTG casing

Oil casing refers to steel pipes used in oil drilling and production and comes in a variety of sizes and specifications.

Common oil casing sizes include:

4 1/2 in. (114.3 mm): Commonly used in shallow wells or as production casing.

5 inches (127 mm): For use in shallower oil and gas wells.

5 1/2 inches (139.7 mm): For use in shallow to medium oil and gas formations.

7 inches (177.8 mm): Used for medium depth oil and gas wells and as production casing.

9 5/8 inches (244.5 mm): used in deeper oil and gas formations and can be used as anti-collapse casing.

Other sizes: There are also large-diameter oil casings such as 13 3/8 inches and 16 inches, which are used for deeper oil and gas wells and protection of water injection parts.

Oil casing plays a very important role in oil drilling and production. Specific uses include:

As a drilling pipe: first use a smaller diameter casing to contact the rock formation, and then drill through the rock formation through a larger diameter casing.

Protect the formation: Petroleum casing protects the formation through which drilling occurs, preventing deformation of the formation and changes in oil and gas reserves. Anti-collapse casing: During drilling, larger casing is installed to prevent the borehole from collapsing.

Support drilling equipment: Casing serves as a necessary part of drilling rig support equipment during the drilling process to ensure the stability of drilling.

Oil casing is an important part of oil drilling. It plays key roles in supporting the well wall, preventing well wall collapse, and controlling bottom well pressure. Therefore, quality inspection of oil casing is crucial to ensure the safety and smooth progress of drilling operations.

The quality testing methods of oil casing mainly include the following aspects:

Appearance inspection: Appearance inspection is one of the most basic quality inspection methods. By carefully observing the appearance of the oil casing, you can check whether there are cracks, deformations, corrosion and other problems. At the same time, it is also necessary to check whether the welds of the casing are complete and whether there are welding defects.

Dimensional measurement: Dimensional measurement is an important part of oil casing quality inspection. By using measuring tools, such as calipers, vernier calipers, etc., measure the diameter, wall thickness and other dimensions of the casing to ensure that it meets the design requirements.

Material testing: Material testing of oil casing is one of the key steps to ensure its quality. Commonly used material testing methods include chemical composition analysis, metallographic structure analysis, hardness testing, etc. These testing methods can check whether the composition of the casing material meets the standard requirements and whether its organizational structure is uniform and dense.

Pressure test: Oil casing needs to withstand high pressure during drilling operations, so pressure test is one of the essential quality inspection methods. By installing the casing on special testing equipment, applying a certain amount of pressure, and observing whether there are leaks, deformations, etc., the casing is ensured that it can withstand the expected working pressure.

Magnetic particle testing: Magnetic particle testing is a commonly used non-destructive testing method, used to detect cracks, defects and other problems on the surface of casing and welds. By coating magnetic powder on the surface of the casing and then applying a magnetic field, the accumulation of magnetic powder at cracks or defects can be observed to determine whether there is a problem with the casing.

Read more: The causes of OCTG casing stuck or What are the grades of OCTG casing?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.