The Role of Seamless Pipes in Offshore Drilling

Offshore drilling is a complex process that requires high-quality materials and equipment for its operations. Seamless pipes are one of the critical components that play a vital role in offshore drilling. They are widely used for the transportation of oil and gas from the seabed to the surface. These pipes are specially designed to withstand the harsh environmental conditions of the sea, including high pressure, extreme temperatures, and corrosive substances. The following article will discuss the role of seamless pipes in offshore drilling, including their properties, applications, and benefits.

Properties of Seamless Pipes

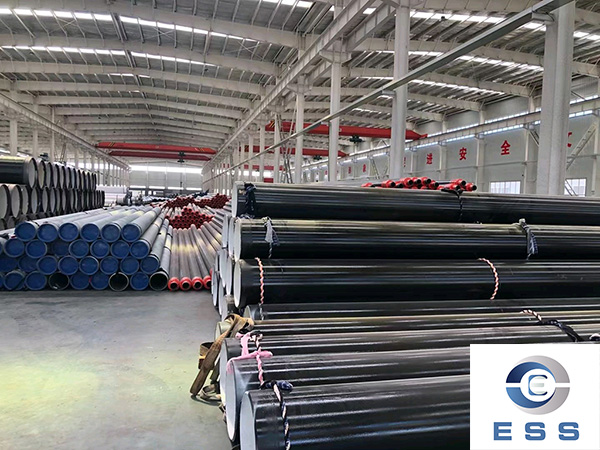

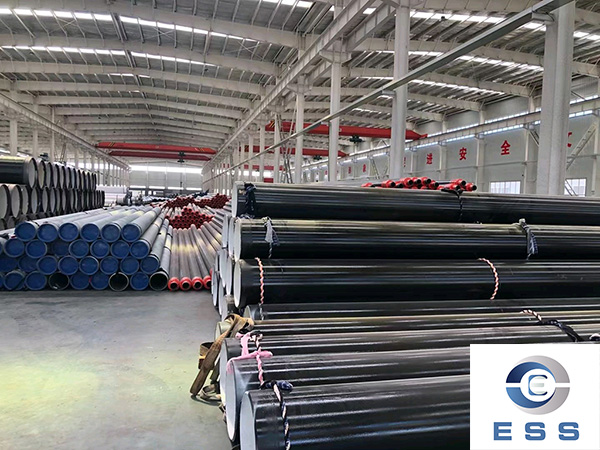

Seamless pipes are made from high-quality steel that has been heated, rolled, and shaped into cylindrical tubes without any seams or joints. The absence of welds and joints makes these pipes stronger, more durable, and less prone to leaks and failures. Seamless pipes have a uniform thickness and diameter, which ensures consistent flow rates and pressure levels. They are also resistant to corrosion, erosion, and wear, which makes them ideal for use in harsh environments.

Applications of Seamless Pipes in Offshore Drilling

Seamless pipes are used in various applications in offshore drilling, including drilling, production, and transportation. In the drilling process, seamless pipes are used as casing and tubing to line the wellbore and protect it from collapse and damage. They also help to control the flow of oil and gas during drilling operations, which improves safety and efficiency.

In the production phase, seamless pipes are used as flowlines to transport oil and gas from the wellhead to the processing plant. They are also used as risers to connect the production platform to the seabed, where the oil and gas reserves are located. Seamless pipes are essential components of the subsea infrastructure, which includes pipelines, manifolds, and control systems.

Benefits of Seamless Pipes in Offshore Drilling

Seamless pipes offer several benefits in offshore drilling, including:

1.High Strength and Durability: Seamless pipes are made from high-quality steel that has been heat-treated and rolled to provide exceptional strength and durability. They can withstand high pressure, extreme temperatures, and corrosive substances, which makes them ideal for use in offshore drilling.

2.Improved Flow Rates and Pressure Levels: Seamless pipes have a uniform thickness and diameter, which ensures consistent flow rates and pressure levels. This improves the efficiency of offshore drilling operations and reduces the risk of failure or leakage.

3.Reduced Maintenance Costs: Seamless pipes require minimal maintenance and repair, which reduces the overall costs of offshore drilling operations. They are less prone to leaks, cracks, and fractures, which reduces the need for frequent inspections and repairs.

4.Increased Safety and Reliability: Seamless pipes are less prone to failure and leakage, which improves the safety and reliability of offshore drilling operations. They also reduce the risk of environmental damage and pollution, which is a significant concern in offshore drilling.

Conclusion

Seamless pipes play a critical role in offshore drilling, providing high-quality, durable, and reliable transport solutions for oil and gas. They are used in various applications, including drilling, production, and transportation, and offer several benefits, including high strength, improved flow rates, reduced maintenance costs, and increased safety and reliability. As offshore drilling continues to grow and evolve, seamless pipes will continue to play a vital role in ensuring the safe and efficient extraction of oil and gas from the seabed.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.