Tubing pup joints are indispensable short-length pipe fittings for connecting oil well pipe strings. They are mainly used to adjust the length

of the tubing string and are widely used in oil and gas exploration, production

and wellhead operations. We provide high-quality tubing pup joints that meet

international standards, adapting to various engineering needs to ensure

construction efficiency and safety.

Tubing pup joints material

1. J55/K55

J55/K55 is suitable for shallow wells and

conventional pressure scenarios.

2. N80/L80

N80/L80 is suitable for medium-deep wells

and medium-pressure wells, with both high strength and corrosion resistance.

3. P110

P110 is suitable for high-pressure wells,

high temperature or sulfur-containing environments, and has super strong

pressure resistance.

Technical standards

1. API SPEC 5CT - technical specifications

for oil casing pipe and tubing.

2. API SPEC 5B - standards for threads and

couplings.

3. ISO 11960 - standards for casing pipe and

tubing for the oil and gas industry.

Length range

The length is less than the R1 standard

length (6.10m), and can be customized to any length according to customer

needs.

Thread type

1. NUE (Non-Upset End) – non-upset thread

2. EUE (External Upset End) – upset thread

3. SCC (Special Clearance Connection) – special clearance thread

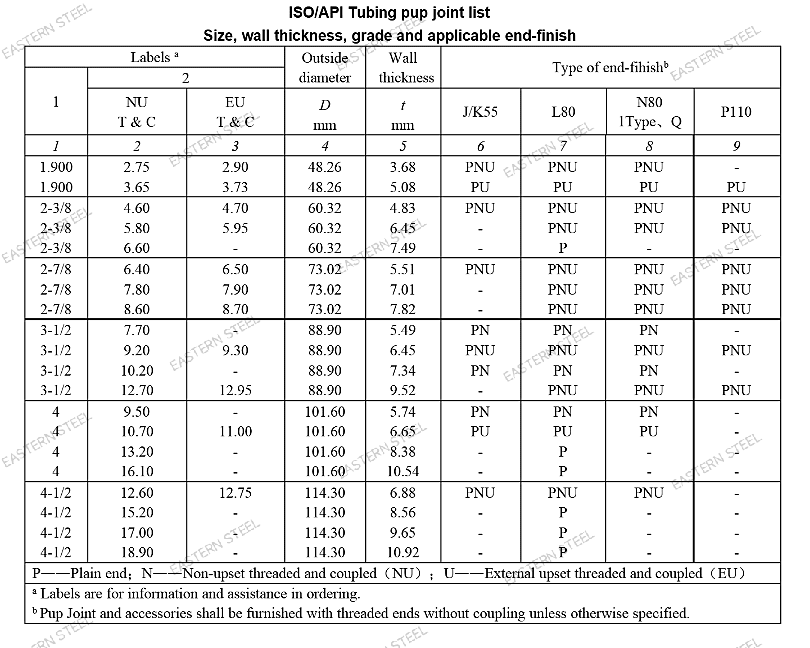

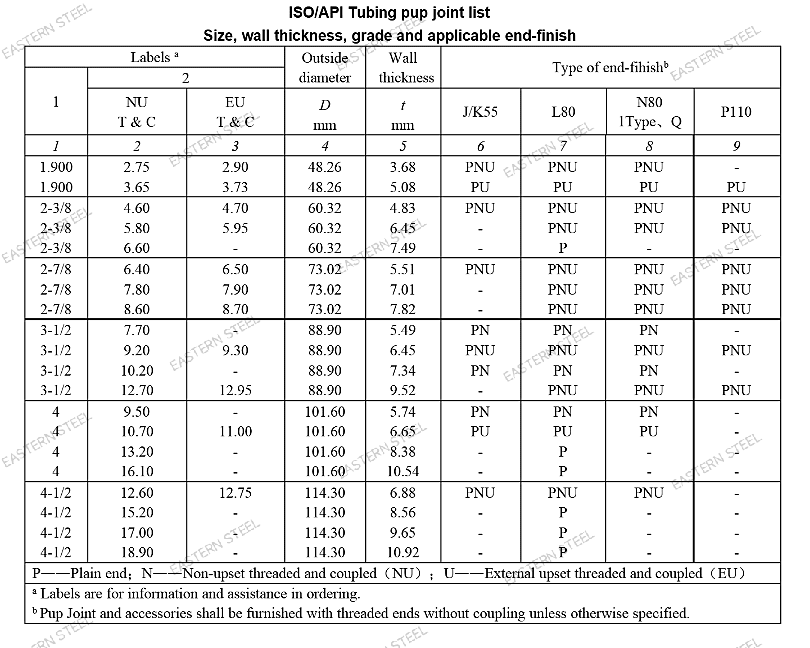

Specifications

1.9", 2-3/8", 2-7/8",

3-1/2", 4", 4-1/2"

Packaging of tubing pup joints

1. Protective treatment

Each tubing pup joint is painted or coated

with anti-rust oil to prevent corrosion during transportation and storage

2. Standard marking

Laser marking on the tubing body according

to API 5CT standard, including: steel grade, size, heat treatment information,

batch number, etc.

3. Safe packaging

Standard steel strapping, optional wooden

box or pallet packaging, suitable for export container transportation. Provide

customized packaging services (such as labeling, plastic caps, waterproof

sealing film, etc.).

Purpose of tubing pup joints

1. Fine adjustment of pipe string length

Tubing shorter than the standard length

range R1 is used for adjusting the pipe string length at the wellhead.

2. Well repair operation

Quick access when replacing damaged pipe

sections.

3. Well testing/logging

Quickly build a pup joint for testing and

measurement.

4. Wellhead emergency treatment

Solve the problem of temporary connection

at the wellhead and improve operation efficiency.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.