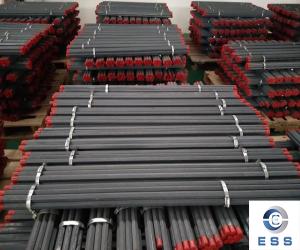

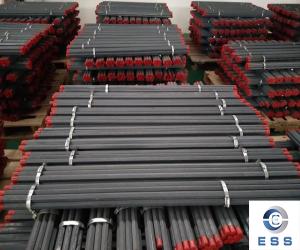

Drill pipe is an indispensable tool in oil extraction work, and it is subjected to complex working conditions such as high temperature and high pressure, strong drilling and rotation force. Therefore, the quality and safety of oil drill pipe is directly related to the stability and safety of extraction work. Casing pipe, tubing,pup joint and drill string components (drill pipe, drill collar, square drill pipe, etc.) are collectively referred to as oil well pipe (OCTG).

What is the service life of drill pipe

The service life of drill pipe refers to the life span of the drill pipe used in the drilling operation. With the increase of drilling depth and the change of formation conditions, the service life of drill pipe will also be different.

Factors affecting the service life of drill pipe

1. Drill pipe material: Drill pipe material is one of the key factors affecting the service life of drill pipe. Commonly used drill pipe materials include carbon steel, alloy steel, stainless steel, etc. The wear resistance and corrosion resistance of different materials will directly affect the service life of drill pipe.

2. Frequency of use of drill pipe: The higher the frequency of drilling operations, the more serious the damage to the drill pipe, and the service life will be shortened accordingly.

3. Formation conditions: Formation conditions are an uncontrollable factor in drilling operations. The physical properties and chemical composition of the formation deposits will have a significant impact on the service life of the drill pipe.

Calculation method of drill pipe service life

The service life of the drill pipe is related to its material, processing technology, use environment and other factors. Generally, the service life of the drill pipe can be calculated by the following two methods:

1. Calculation by time

That is, the service life of the drill pipe is estimated according to the length of time the drill pipe is used. Generally, high-quality drill pipes can be used for weeks to months, while low-quality drill pipes may only be used for a few days.

2. Calculation by number of uses

That is, the service life of the drill pipe is calculated according to the number of times the drill pipe is used. When the number of uses is equal, the service life of high-quality drill pipes is longer.

Maintenance tips for drill pipes

Proper maintenance can extend the service life of the drill pipe and reduce drilling costs. The following are some common maintenance tips:

1. Cleaning before use

The drill pipe should be carefully cleaned before use to ensure that its surface is clean and free of debris to avoid wear of the drill pipe by foreign substances.

2. Regular inspections

Inspect the surface and joints of the drill pipe regularly, and replace or repair them in time if any problems are found.

3. Avoid high-intensity impacts

During use, avoid high-intensity impacts or twisting to avoid damage to the drill pipe.

4. Avoid excessive wear

Avoid excessive wear and replace worn parts in time to avoid affecting the overall life of the drill pipe.

Effective methods to extend the life of the drill pipe

The life of the drill pipe can be effectively extended by the following methods:

1. Select high-quality drill pipe materials

Selecting high-strength, high-hardness, and corrosion-resistant drill pipe materials can effectively extend the service life of the drill pipe and reduce drilling costs.

2. Choose the right way to use

Choosing the right way to use, such as controlling the speed, avoiding excessive impact, avoiding frequent replacement of drill bits, too frequent downhole operations, etc., can reduce the degree of damage to the drill pipe and extend its service life.

3. Regular maintenance and maintenance

Regular maintenance and maintenance of the drill pipe can eliminate potential problems, discover the degree of damage to the drill pipe, and promptly handle and replace damaged parts to avoid problems from aggravating and affecting the service life of the drill pipe.

Summary

In summary, as the core component of drilling equipment, the service life of drill pipe is directly related to the efficiency and cost of drilling. The service life of drill pipe is one of the important factors to be considered in drilling projects. By selecting high-quality drill pipe materials, using drill pipe reasonably, and performing regular maintenance, the service life of drill pipe can be extended, the drilling efficiency can be improved, and the operating cost can be reduced.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.