High-pressure drilling is a very important

part of oil and gas exploration, and pup joints are an indispensable part of the drilling process. It plays an important role

in speeding up drilling speed and improving drilling efficiency.

Application of pup joints in

high-pressure drilling

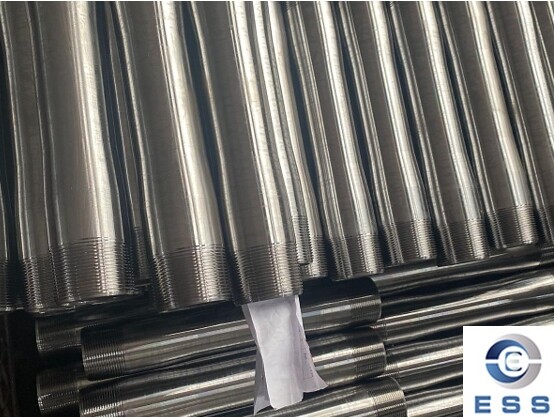

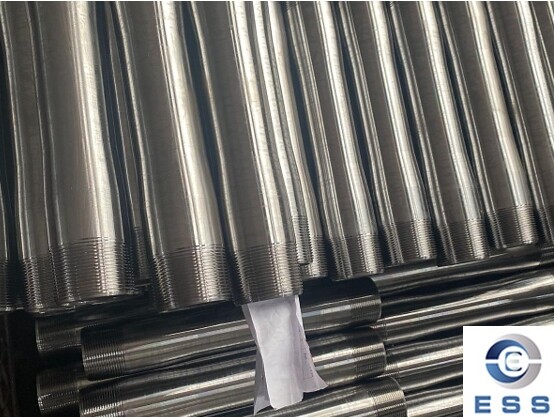

1. Increase the length of drilling tools

The most basic function of pup joints is to

increase the length of drilling tools, which can slightly increase the drilling

depth and reduce the number of drilling times. At the same time, pup joints can

also ensure that drilling tools can work smoothly without frequent replacement

of drill bits, drilling tools, etc.

2. Connecting pipes

During the drilling process, pup joints are

often used to connect drill pipe,

mud pipe, lifting pipe, etc. of the same diameter. They help ensure that the

pipeline connection is stable and the fluid will not fail due to loose pipe

interfaces or oil or gas leaks.

3. Simplify installation and maintenance

The installation of pup joints is

relatively simple, and they are often fixed by welding, threaded connections or pipe flange connections. This makes it more convenient to maintain in drilling operations

and reduces system downtime.

4. Withstand vibration and impact

During drilling operations, pipelines are

often subjected to vibration and impact, and the pup joint must be able to

withstand these impact forces to avoid loosening or rupture of the pipeline due

to long-term vibration.

Factors to consider when selecting a pup

joint

1. Material strength

Due to the harsh working environment of the

high-pressure drilling system, it is necessary to ensure that the material has

sufficient strength and corrosion resistance when selecting a pup joint.

Commonly used materials include alloy steel pipes, duplex stainless

steel pipes, etc.

2. Temperature resistance

The pup joint must be able to withstand the

high temperature environment that may occur during drilling, ensuring that it

can still maintain good sealing and strength under extreme temperatures.

3. Connection method

Different high-pressure drilling systems

may use different connection methods, such as welding, threaded connection,

etc. Choosing the right connection method is crucial to the stability of the

system.

Summary

In high-pressure drilling, it is very

important to correctly select and use the pup joint. The pup joint can increase

the length of the drill bit, connect the pipeline, withstand vibration and

impact, etc. Through reasonable drill bit selection, configuration of drilling

tools and setting of drilling procedures, the advantages of the pup joint can

be better utilized to improve drilling efficiency and reduce costs.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.