Insufficient hardness of seamless pipe after quenching

In production, sometimes there will be insufficient hardness after quenching, which is a common defect in the heat treatment and quenching process. "Insufficient hardness" has two manifestations, one is the low hardness value of the entire workpiece, and the other is insufficient local hardness or soft spots. When the phenomenon of insufficient hardness occurs, it is necessary to analyze the "insufficient hardness" by means of hardness test or metallographic analysis, and then find the reason from the aspects of raw materials, heating process, cooling medium, cooling method and tempering temperature, etc., so as to find out the reason. Come up with a solution.

1. Raw materials

1.1 Improper selection of raw materials or delivery of wrong materials

The wrong use of low carbon steel for parts made of medium carbon steel or high carbon steel, and the wrong use of ordinary high carbon steel for parts made of alloy tool steel will result in insufficient hardness or soft spots.

Example 1: The gear made of 45 steel should be used, and its quenching hardness should be about 60HRC, but 25 steel is wrongly selected, and the result is about 380HBS.

Example 2: The mold should be made of 9Mn2V, but it is wrongly used as T8 steel. Since the sparks of 9Mn2V and T8 steel are difficult to distinguish, it is wrongly quenched according to the quenching process of 9Mn2V when quenching, and oil cooling is used. The result is that the hardness is only about 50HRC.

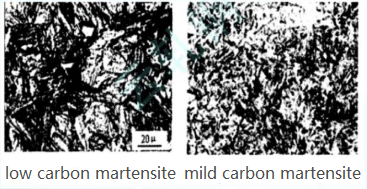

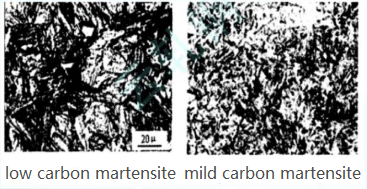

The above two cases belong to insufficient overall hardness, and hardness test or metallographic test can be used (25 steel is quenched to obtain low-carbon martensite, as shown in Figure 1, and 45 steel is quenched to obtain medium-carbon martensite, as shown in Figure 2) to judge.

Solution:

1) Appropriate materials should be selected during design;

2) To strengthen material management, chemical analysis is carried out before the materials are put into the warehouse, and then they are classified and marked, which can effectively avoid sending wrong materials;

3) The heat treatment operator should conduct spark analysis before operation to roughly identify whether the part material meets the requirements of the drawing;

4) When the workpiece section is large or the thickness of the workpiece section is very different, if tool steel is used, due to its poor hardenability, the inner hardness of the large section will be low. At this time, alloy steel with good hardenability should be used .

1.2 Insufficient local hardness or soft spots due to uneven microstructure of raw materials One of the following situations occurs in the microstructure: Carbide segregation or aggregation, such as ferrite aggregation, graphite, severe Widmansterite structure, etc. will all have insufficient hardness or softer. Solution: Perform repeated forging or preparatory heat treatment (such as normalizing or homogenizing annealing) before quenching to homogenize the structure.

2. Heating process

2.1 The quenching heating temperature is low and the holding time is insufficient

Such as hypoeutectoid steel, when the heating temperature is between Ac3 and Ac1 (for example, the quenching heating temperature of 25# steel is lower than 860°C), because the ferrite is not completely dissolved into the austenite, it cannot be uniform after quenching. Martensite, ferrite and martensite are obtained, which affect the hardness of the workpiece. Undissolved ferrite can be seen from metallographic analysis.

For high-carbon steel, especially high-alloy steel, if the heating or holding time is insufficient, pearlite cannot be transformed into austenite, and martensite cannot be obtained. In actual production, the above situation is often due to the deviation of the instrument indication (the indicated temperature is too high) or the uneven temperature of the furnace, which makes the actual temperature of the workpiece low; the estimation of the thickness of the workpiece is wrong, causing the holding time to be too short.

Solution:

1) Control the heating speed well to avoid excessive heating speed, resulting in uneven furnace temperature, and at the same time, it will cause premature heat preservation timing, so that the heat preservation time is insufficient;

2) Frequently check whether the temperature indicating instrument is intact and accurate, and avoid the phenomenon that the indicating instrument shows the reached temperature but the actual temperature is insufficient;

3) Determine the quenching heating rate and heating temperature strictly according to the material manual to prevent the quenching temperature from being too low or too high;

4) Correctly estimate the material thickness, especially for special-shaped parts.

2.2 The quenching heating temperature is too high and the holding time is too long

For tool steel (such as T8 steel), when the quenching temperature is 780°C, austenite and carbide (Fe3C) are obtained. At this time, the dissolved carbon content of austenite is slightly higher than 0.77%. body transforms into martensite. If the heating temperature is too high or the holding time is too long, a large amount of carbon in the carbide (Fe3C) will be dissolved into the austenite, resulting in a high amount of dissolved carbon in the austenite, and at the same time greatly increasing its stability, so that the austenite tends to Martensite (A-M) transforms, and the temperature begins to drop, so a large amount of retained austenite remains in the workpiece after quenching, and the obtained structure is M+A', because the retained austenite has austenite properties, that is, hardness Low, resulting in a decrease in hardness after quenching. Effect of heating temperature and tempering temperature on retained austenite content.

Solution:

1) Strictly control the quenching heating temperature and holding time to prevent excessive carbon from dissolving into austenite, and it is more important to control the heating temperature;

2) Reduce the quenching cooling rate, or adopt graded quenching, so that the supercooled austenite can fully transform into martensite;

3) Adopt cold treatment to transform the retained austenite to martensite;

4) High temperature tempering is used to reduce the residual austenite, and the hardness will increase instead.

2.3 When quenching and heating, the surface of the workpiece is decarburized

After 45# steel is quenched, through metallographic analysis, its surface is ferrite and low-carbon martensite, and after grinding off the decarburized layer on the surface, the hardness meets the requirements. This situation often occurs in box furnaces without protection Or poor protection, or heating in a salt bath with poor deoxidation, causing oxygen to react with carbon atoms in the workpiece to form CO, reducing the carbon content on the surface of the workpiece, so that the surface hardness is insufficient.

Solution:

1) Use a non-oxidizing heating furnace with a protective atmosphere, such as a protective atmosphere for cracking with alcohol or methanol;

2) Vacuum heating and quenching;

3) For general box-type furnaces, pig iron chips or charcoal can be used to pack and seal; the surface of the workpiece is coated with anti-oxidation coating: put charcoal in the furnace; the workpiece is coated with boric acid and alcohol solution and then heated.

3. Cooling process problems

3.1 Improper selection of quenching medium

The water quenching or salt bath workpiece adopts oil cooling, because the cooling capacity is insufficient and the cooling speed is too slow, during the cooling process, austenite transforms into pearlite type structure (A→P), and martensite cannot be obtained. body (M) (especially in the core of the workpiece), resulting in low hardness of the workpiece. For example, the hand hammer made of T 10 is quenched in oil, and the hardness is only about 45HRC. Through metallographic analysis, it can be seen that the obtained troostite structure rather than martensite.

Solution: The appropriate cooling medium must be selected according to the material and shape of the workpiece.

3.2 Influence of quenching medium temperature

During water quenching, a large number of parts are continuously quenched. If there is no circulating cooling system, the water temperature will rise, the cooling capacity will decrease, and the quenching will not be hardened. When the oil is cooled, due to the low temperature and poor fluidity of the oil at the beginning of quenching, the cooling capacity is not strong, resulting in hard quenching.

Solution: When water quenching, a circulating cooling system should be used, and it is advisable to keep the water temperature at about 20°C; when oil is cooled, especially at the beginning, it should be properly heated to make the temperature above 80°C. Said "cold water hot oil" truth.

3.3 The medium is too old during quenching

When the alkali (salt) bath containing more impurities or the water is too little, it is easy to produce quenching soft spots. Solution: The quenching medium should be replaced in time and the moisture in the alkali (salt) bath should be controlled.

3.4 Improper cooling time control

When carbon steel is used to manufacture parts with complex switches or large cross-sections, water quenching-oil cooling is used to prevent deformation and cracking. If the part stays in the water for too short time or stays in the air for too long after taking it out of the water and then transfers it to the oil, due to the high temperature of the part itself, especially the slow cooling rate of the core, uniform and complete martensite cannot be obtained.

Solution: Properly control the water cooling time. If you use pliers to hold the workpiece, when the hand feels no vibration, immediately transfer it to the oil; for the mold with a large cavity, the waste should be removed first, the thickness of the workpiece should be reduced, and then quenched . During step quenching, if the residence time in the salt bath is too long, bainite transformation will occur, resulting in insufficient hardness. In short, insufficient quenching often occurs, and the operator should analyze and find out the reasons according to different situations and overcome them.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.