Hydraulic

Tubes Service Life Standard

The service life standard of hydraulic tube

is based on a comprehensive consideration of multiple factors such as pipe

material, working pressure, working temperature and application environment.

The service life of hydraulic tubes is generally around 5000~10000 hours, but

it depends on whether the application environment is harsh, the quality of the

hydraulic pipes, and whether the hydraulic system is used in a standardized

manner. In the process of using hydraulic tubes, attention should be paid to the

detection and maintenance of service life, and aging hydraulic pipes should be

replaced in time to avoid damage to equipment caused by aging of hydraulic

tubes.

Factors Affecting The Service Life of Hydraulic

Tubes

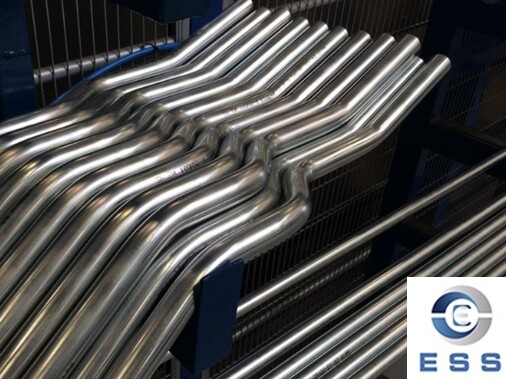

The quality of hydraulic tubes has a great

influence on their service life. Hydraulic tubes with higher quality generally

have a longer service life. However, the service life of hydraulic tubes

produced by some merchants is very short, and aging may occur after only about

1 month of use. When purchasing hydraulic tubes, you can choose according to

the quality information of hydraulic tubes and the credibility of

manufacturers.

Maintenance Methods of Hydraulic Tubes

1. When using hydraulic tubes, pay

attention to the fit of the pipe interface to avoid oil leakage in the pipe and

rust on the surface of the material.

2. Hydraulic tubes should be avoided under

abnormal temperature, pressure, etc., which will cause the pipe to age and

crack.

3. Do not bend the hydraulic tube for a

long time during use. Long-term bending will cause deformation of the pipe

wall, thinning or brittleness of the pipe.

4. Check the service life of the hydraulic

tube regularly and replace the aged hydraulic tube in time.

5. Clean the dirt and oil on the inner wall

of the hydraulic tube in time to ensure the smoothness of the sliding surface

inside the pipe.

Summary

Through the maintenance and maintenance of

the hydraulic tube, the service life of the hydraulic tube can be extended, the

working efficiency of the equipment can be improved, and the occurrence of

failures can be reduced. During use, attention should also be paid to the

cleaning of the pipeline to prevent dust and impurities from entering the

hydraulic tube and affecting the normal operation of the hydraulic system. At

the same time, the maintenance of the hydraulic system is also very important.

The hydraulic oil and filter element need to be replaced regularly to ensure

the normal operation of the hydraulic system.

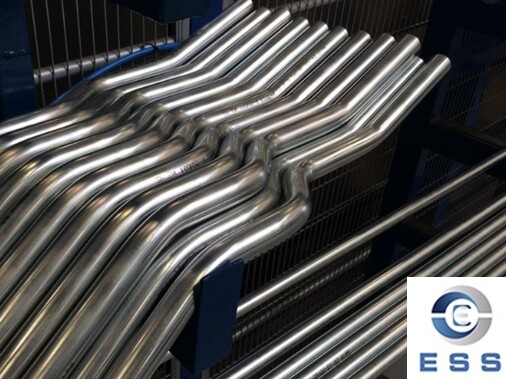

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.