Square tubes (SHS

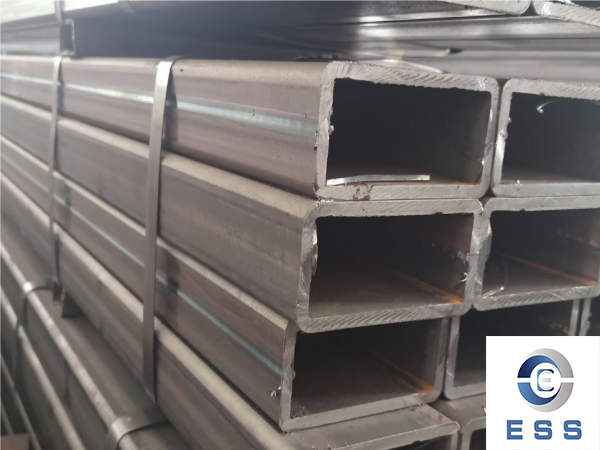

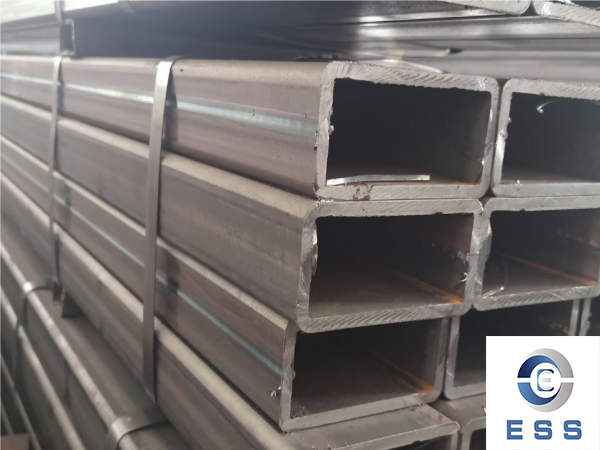

steel) and rectangular tubes

(RHS steel) are collectively referred to as Hollow

Structural Sections (HSS).

They are typically manufactured from

hot-rolled or cold-rolled strip steel through processes such as uncoiling,

flattening, rolling, welding, shaping, and cutting to length.

They can also be obtained through secondary

forming of hot-rolled seamless

steel pipes. Due to their different cross-sectional shapes, they differ

significantly in strength distribution, load-bearing capacity, applications,

and costs.

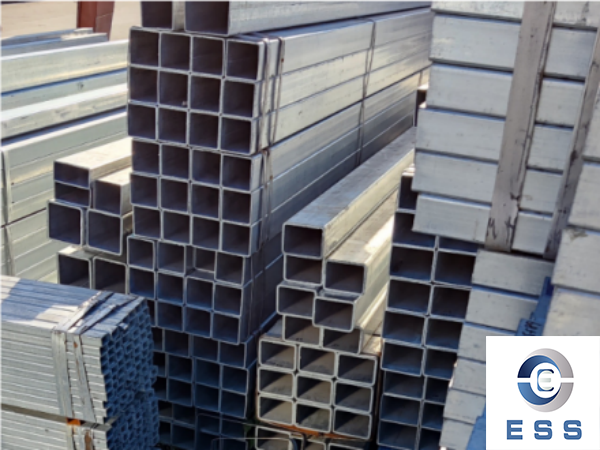

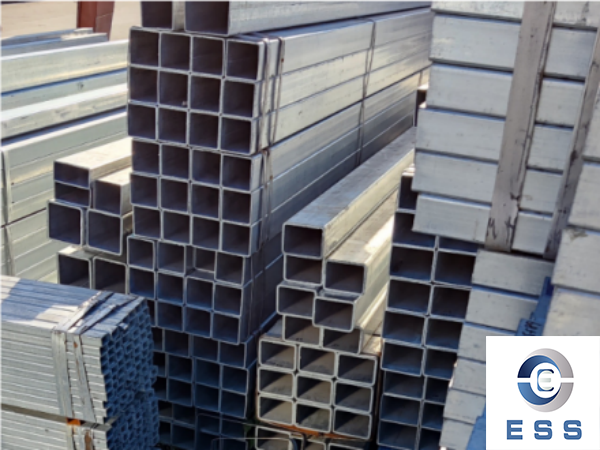

Square Tube Meaning

1. Material Structure of Square Tubes

Square tubes have a square cross-section

with four equilateral right angles.

Square tubes can be manufactured using

various processes such as hot rolling, cold rolling, cold drawing, or hot-dip

galvanizing, offering advantages such as low production costs and high

production efficiency.

3. Square Tube Sizes

Common sizes: 10×10mm,

20×20mm, 25×25mm, 40×40mm, 50×50mm, 100×100mm,

150×150mm

Wall thickness range: 0.6mm – 6.0mm

Length: Standard length 6m (customizable up

to 12m).

4. Load-Bearing Capacity of Square Tubes

Square tubes are superior in withstanding

bending loads and can withstand greater bending forces.

5. Applications of Square Tubes

Square tubes are widely used in petroleum,

chemical, power, and automotive industries, such as in automobile frames and

petrochemical oil pipelines.

Rectangular Tube Meaning

1. Material Structure of Rectangular Tubes

Rectangular tubes have a rectangular

cross-section with four right angles.

2. Manufacturing Process of Rectangular

Tubes

Rectangular tubes are generally

manufactured using hot rolling or cold rolling processes, resulting in

relatively high production costs.

Common sizes: 20×30mm,

25×50mm, 40×80mm, 50×100mm, 80×120mm, 100×200mm

Wall thickness range: 0.8mm – 8.0mm

Length: Standard 6m, custom lengths

available upon request.

4. Load-Bearing Capacity of Rectangular

Tubes

Rectangular tubes have higher strength than

square tubes for the same cross-sectional area.

5. Applications of Rectangular Tubes

Rectangular tubes are commonly used in

construction, machinery manufacturing, and other fields, such as steel frame

structures and corridor railings.

1. Choose Based on the Direction of Force

Choose square tubes (SHS steel):

When a structure needs to withstand

bending, torsion, or lateral forces from multiple directions (e.g., columns,

support frames, vehicle frames, machinery frames).

Square tubes, due to its symmetrical

cross-section, exhibits consistent strength in all directions, making it better

able to resist multi-directional stresses and torques.

Typical applications: automotive chassis,

towers, machinery frames, railings, equipment supports.

Choose rectangular tubes (RHS steel):

When the direction of force is clear (e.g.,

vertical compression or horizontal bending), rectangular tubes has stronger

bending resistance along its long side, allowing it to withstand greater loads

with the same material usage.

Typical applications: Building beams and

columns, portal frames, corridor structures, warehouse racking.

2. Selection Based on Structural Design and

Space Dimensions

Select square tubes (SHS steel):

When space is limited and a square and

symmetrical shape is required.

Square tubes has a compact cross-section,

suitable for columns, square frames, decorative structures, etc.

It also has a more harmonious appearance

and is often used in building facades, furniture, landscape railings, and other

applications requiring aesthetic appeal.

Select rectangular tubes (RHS steel):

For larger spans, material usage needs to

be optimized.

Rectangular tubes can more efficiently

distribute the moment of inertia of the material in the main force direction,

reducing weight and cost in beams, support arms, and frame beams.

3. Economic and Cost Considerations

Rectangular tubes offer superior structural

efficiency and lower costs. Square tubes offer advantages in symmetrical stress

distribution and aesthetic harmony.

4. Connection and Welding Requirements

Square tubes are easier to align during

welding, making them suitable for square nodes and symmetrical connection

structures.

Rectangular tubes require careful attention

to weld design and stress symmetry along their long and short sides during

connection.

For complex node stresses or situations

with limited weld space, square tubes are generally easier to install.

5. Quality Certification

When purchasing, ensure that the square

tubes meet relevant standards and quality certification requirements to

guarantee their reliability.

6. Price Comparison

In addition to the above factors, you

should compare the prices of square and rectangular tubes from different

suppliers or brands and make a final choice based on cost-effectiveness.

How to Identify Inferior Square Tube and

Rectangular Tubes?

1. Observe Creases and Ripples

High-quality tubes have a smooth surface,

while inferior products are prone to wrinkles or creases.

2. Check Weld Quality

Welds should be uniform and free of

porosity. Inferior pipes often exhibit weld cracks or incomplete penetration.

3. Touch and Gloss

High-quality pipes have a smooth surface

and a metallic luster; inferior pipes appear reddish or dull.

4. Measuring Wall Thickness

Use calipers to measure whether the wall

thickness matches the nominal thickness. Inferior products often misrepresent

their thickness.

5. Brand and Certification

Choose reputable manufacturers with ISO

certification and factory inspection reports.

FAQ

1. SHS Steel vs. RHS Steel: Which is Cheaper?

Prices may vary depending on:

Size and wall thickness

Steel grade and coating (galvanized or raw

steel)

Cutting and processing requirements

Generally, rectangular steel pipes (RHS)

may be slightly cheaper per meter, especially for larger spans, as it achieves

the required strength with less material. However, square steel pipes (SHS) are

generally more common in general-purpose construction.

2. Are Rectangular Tubes Recyclable?

Yes, rectangular tubes are recyclable.

It

is typically made of carbon steel, stainless steel, or aluminum, all of which

are 100% recyclable and can be used to manufacture new metal products, making

it both environmentally friendly and energy-efficient.

Summary

In summary, when choosing between square

tubs (SHS) and rectangular tubs (RHS), the direction of force, load-bearing

requirements, appearance requirements, and cost factors should be considered

comprehensively: if multi-directional load-bearing performance and aesthetic

harmony are desired, choose square tubs; if high bending resistance and

material efficiency are desired, choose rectangular tubs.

Read more: SHS Steel vs. CHS Steel: Which is Stronger?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.