In the oil and gas industry, choosing the

right OCTG pipe supplier is crucial. The quality and performance of OCTG pipes directly affect

the safety and efficiency of oil and gas wells. This article will introduce you

to the 6 key factors to consider when evaluating OCTG pipe suppliers to help

you make a wise choice.

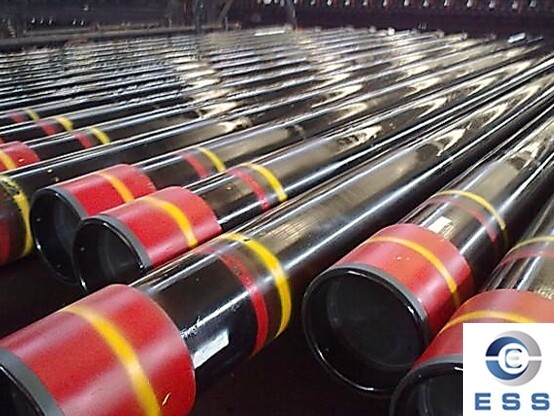

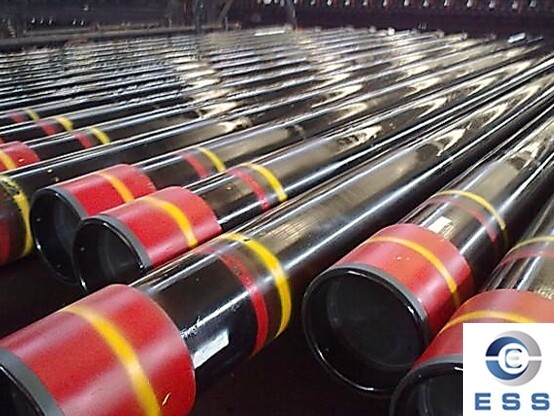

Product Quality

1. Material Selection

OCTG pipes usually use carbon

steel pipe, alloy steel pipe or stainless

steel pipe. High-quality OCTG pipes should meet international standards

such as API 5CT or ISO 11960.

2. Performance Testing

Suppliers should provide detailed test

reports, including tensile strength, yield strength, hardness, corrosion

resistance and fatigue resistance.

Production Capacity and Technology

1. Production Scale

Choosing a supplier with a larger

production scale can ensure stable supply capacity.

2. Advanced Equipment

Advanced production equipment and

technology can improve product quality and production efficiency.

Certification and Standards

1. API Certification

API certification is an authoritative

certification in the oil and gas industry, ensuring that products meet

international standards.

2. ISO certification

ISO certification indicates the supplier's

compliance with international standards in quality management and production

processes.

After-sales service

1. Technical support

Suppliers should provide professional

technical support, including product selection, technical consultation and

on-site service.

2. After-sales guarantee

A complete after-sales service system can

promptly solve problems that arise during product use.

Price and delivery time

1. Price comparison

On the premise of ensuring product quality,

compare the prices of different suppliers and choose products with high cost

performance.

2. Cost control

Suppliers should provide a reasonable price

structure to help customers control costs.

3. On-time delivery

Suppliers should have good production

planning and logistics management capabilities to ensure on-time delivery.

4. Emergency response

In an emergency, suppliers should be able

to respond quickly and provide solutions.

Reputation and cooperation attitude

1. Market reputation

Choosing a supplier with a good market

reputation can reduce cooperation risks.

2. Customer evaluation

Refer to other customers' evaluations and

feedback to understand the supplier's service quality and product reliability.

3. Value customers

Suppliers should regard customers as

important partners and actively meet their needs.

4. Joint improvement

Suppliers should actively participate in

customers' quality improvement projects and jointly improve product and service

levels

Summary

When evaluating OCTG pipe suppliers, it is

necessary to comprehensively consider 6 key factors, including product quality,

production capacity and technology, certification and standards, after-sales

service, price and delivery time, reputation and cooperative attitude. Through

comprehensive evaluation and selection of suppliers that meet the requirements,

the quality and performance of OCTG pipes can be ensured, and the safety and

efficiency of oil and gas wells can be improved.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.