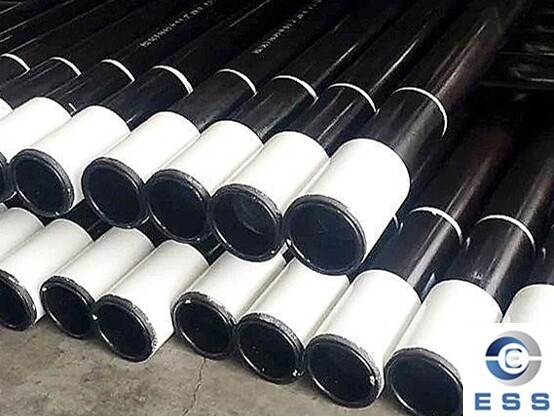

Wear-resistant tubing pup joints are generally composed of a wear-resistant layer added to the outer wall of the seamless

pipe. The wear-resistant layer is usually made of wear-resistant materials

such as polymer materials, ceramics, and silicon carbide, which can effectively

resist medium erosion and wear. In addition, the wear-resistant tubing pup

joint needs to be installed with accessories such as sealing rings and locking

devices to ensure the sealing and stability of the connection.

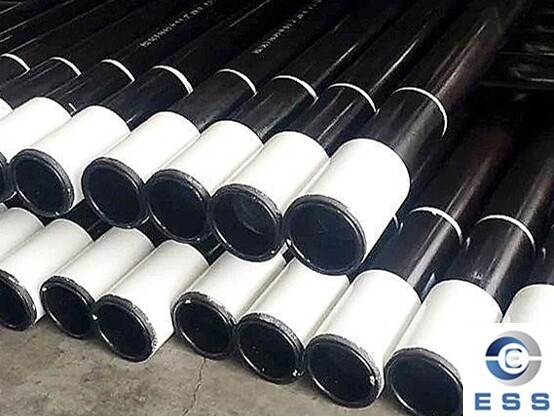

Wear-resistant tubing pup joint is a

commonly used pipeline fitting in the fields of petroleum, chemical industry,

and electric power. Its function is to connect the tubing and equipment and

protect the pipeline from damage such as wear and corrosion. So, why should we

choose wear-resistant tubing pup joint? What are the advantages of

wear-resistant tubing pup joint? What should we consider when choosing a

wear-resistant tubing pup joint?

What are the advantages of

wear-resistant tubing pup joint?

1. High wear resistance

The wear-resistant layer material has high

wear resistance and can effectively extend the service life of the pipeline.

2. Good sealing performance

The sealing ring and locking device ensure

the sealing performance of the connection and prevent the leakage of the

medium.

3. Easy installation

The wear-resistant oil pipe pup joint is

simple to install and easy to operate, which can meet the installation

requirements of different occasions.

4. Strong corrosion resistance

The materials such as the wear-resistant

layer and the sealing ring have good corrosion resistance and can resist the

erosion of various chemical media.

5. Low maintenance cost

The wear-resistant oil pipe pup joint has a

long service life, which can reduce the number of replacements and reduce

maintenance costs.

How to choose a wear-resistant oil pipe

pup joint?

1. Understand the needs

When choosing a wear-resistant oil pipe pup

joint, you must first clarify the use occasions and conditions, such as the

conveying medium, temperature, pressure and other parameters, so as to select

the appropriate model and material. If used for oil extraction, it is also

necessary to consider the compatibility with other pipeline systems such as drill pipe and casing pipe.

2. Choose suitable wear-resistant materials

The wear-resistant layer materials of the

wear-resistant oil pipe pup joint mainly include polymer materials, ceramics,

silicon carbide, etc. Different materials are suitable for different working

conditions. When purchasing, it is necessary to select the appropriate

wear-resistant layer material according to the working conditions to ensure the

durability and stability of the pup joint.

|

Material

|

Advantages

|

Disadvantages

|

Application

|

|

Polymer materials (such as polyurethane,

rubber)

|

Have good elasticity and impact

resistance, light weight, and easy installation.

|

Poor high temperature resistance,

slightly lower wear resistance than ceramics and silicon carbide.

|

Suitable for medium and low temperature

and mild wear environments, such as oil transportation.

|

|

Ceramic materials (such as alumina

ceramics)

|

High hardness, strong wear resistance,

excellent corrosion resistance.

|

High brittleness, poor impact resistance,

and high processing cost.

|

Suitable for high wear and corrosion

medium transportation, such as slurry and mortar.

|

|

Silicon carbide material

|

Extremely high hardness, second only to

diamond, high temperature resistance, wear resistance.

|

Large brittleness, high cost, and high

processing difficulty.

|

Suitable for high temperature and high

wear conditions, such as metallurgy and coal transportation.

|

3. Formal channels

It is recommended to choose formal channels

for purchase, such as large online shopping malls or physical stores. The

product quality of these channels is relatively guaranteed, and there is a

complete after-sales service system. In addition, try to choose products with

relevant certifications, such as wear-resistant tubing pup joints that meet API

(American Petroleum Institute) standards to ensure reliable quality.

4. Check product details carefully

In addition to understanding basic

parameters such as product models and specifications, you also need to pay

attention to details such as wear-resistant layer materials, thickness, sealing

ring materials, and locking methods.

Wear-resistant layer thickness: The

thickness of the wear-resistant layer directly affects the service life. Too

thin may cause premature wear and failure.

Sealing ring material: Corrosion-resistant

and high-temperature resistant sealing materials such as fluororubber or

polytetrafluoroethylene should be selected to ensure sealing performance.

Locking device: The locking method should

be firm and reliable, able to withstand working pressure, and avoid loose

connections and leakage.

What is the quality inspection method

for wear-resistant tubing pup joints?

In order to ensure the quality of

wear-resistant tubing pup joints, it is recommended to perform the following

tests before purchase or use:

1. Dimensional accuracy inspection

Use digital calipers or laser measuring

equipment to check whether the outer diameter, inner diameter, and wall

thickness of the tubing pup joints meet the standards. If it is a precision

tube or heat

exchanger tube, the accuracy requirements are higher and special attention

should be paid.

2. Pressure test

Use water pressure or air pressure testing

equipment to test the bearing capacity of the oil pipe pup joint under high

pressure to ensure that there will be no leakage or deformation.

3. Wear resistance test

Use a wear tester to test the wear

resistance of the wear-resistant layer to evaluate its service life.

4. Corrosion resistance test

Put the pup joint in a specific acid and

alkali solution to observe its corrosion and ensure that its chemical corrosion

resistance meets the use requirements.

5. Sealing test

Perform an air tightness test or a water

tightness test to check whether the sealing ring effectively prevents leakage.

6. Material composition test

Use spectral analysis technology to detect

the composition of the wear-resistant layer material to ensure that it meets

the design standards.

Summary

When selecting a wear-resistant oil pipe

pup joint, it is necessary to select suitable wear-resistant materials

according to the actual working conditions, and pay attention to product

quality and performance testing to ensure that it can operate stably under high

wear, high pressure or corrosive environments. Purchasing through formal

channels and screening in combination with detection methods can effectively

improve the service life and safety of the pipeline system.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.