How should seamless elbows be cleaned?

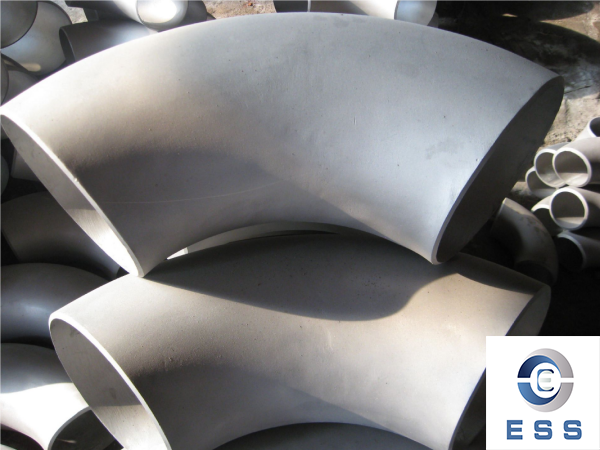

The seamless elbow is made of a whole piece of metal, and the steel pipe without seams on the surface is called a seamless elbow. According to the production method, the seamless pipe is divided into hot-rolled pipe, cold-rolled pipe, cold-drawn pipe, extruded pipe, Jacking pipe etc. Seamless elbows are divided into two types: round and special-shaped according to the cross-sectional shape, and special-shaped pipes have various complex shapes such as square, oval, triangular, hexagonal, melon-shaped, star-shaped, and finned pipes. The largest diameter is 650 mm, the smallest diameter is 0.3 mm, and there are thick-walled tubes and thin-walled tubes depending on the application. Seamless elbows are mainly used as petroleum geological drilling pipes, cracking pipes for petrochemical industry, boiler pipes, bearing pipes, and structural steel pipes with better precision for automobiles, tractors, and aviation.

How to clean the seamless elbow?

Generally speaking, seamless elbows are made of carbon-bonded steel such as 10, 20, 30, 35, 45, low-alloy structural steel such as 16Mn, 5MnV, or combined steel such as 40Cr, 30CrMnSi, 45Mn2, 40MnB, etc., 10, 20, etc. Seamless pipes made of low carbon steel are mainly used for fluid conveying pipes. Seamless tubes made of medium carbon steel, such as 45 and 40Cr, are used in the manufacture of mechanical parts, such as stressed parts of automobiles and tractors. Generally, it is necessary to determine the strength and flattening test of seamless elbows. Hot-rolled steel pipes are delivered in a hot-rolled or heat-treated state; cold-rolled steel pipes are delivered as heat-treated.

Due to the inhomogeneity of deformation during the cold drawing of seamless elbows, the degree of deformation is different from the outer surface layer to the inner surface layer, and the additional bending deformation and additional shear deformation near the outer surface layer are larger, so the total deformation degree The outer layer is larger than the inner layer, therefore, the outer grain is finer and the hardness is better, and the inner layer is the opposite. If the pipe wall is thicker, the friction coefficient is larger, the cone angle of the mold is larger, the difference in the total deformation degree of the inner and outer layers is also greater, and the unevenness of the structure and performance increases, because the deformation degree of the inner and outer layers is different, the seamless elbow After deformation, the tissue properties of the inner and outer layers are inconsistent.

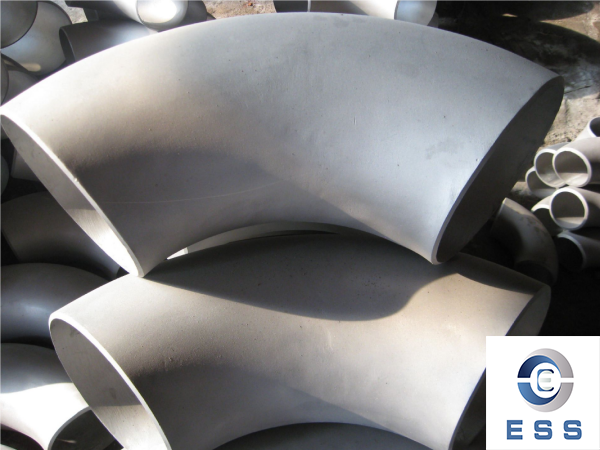

In the process of cleaning the seamless elbow, it is necessary to use its emulsion, solvent and other materials to clean the steel surface so that it can remove grease, lubricant, grease and other similar organic substances, but it cannot remove the rust and welding on the steel surface, so In production only as a secondary trick. In the process of rust removal of seamless elbows, the surface of the steel can be polished with a wire brush first, and these can be added to the processing of seamless elbows to remove loose, raised scale, welding slag and rust.

In the pickling process, the seamless elbow needs to undergo electrolysis and chemical treatment. In order to prevent corrosion of the seamless elbow, only chemical pickling is used to remove rust, old coating, scale and other substances. The chemical cleaning of the seamless elbow can make the appearance reach the necessary cleanliness and roughness, but the anchor pattern of the whole product is shallow, and it is easy to form pollution. In the process of spraying and derusting the seamless elbow, its high-power motor drives the spraying blades to rotate, which will cause abrasives such as steel shots, iron wire segments, steel sand, minerals, etc. to spray the surface of the seamless elbow under centrifugal force.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.