Well casing pipe is a critical component for maintaining the proper functioning of a

water well system. It acts as a barrier, isolating the wellbore from the

external environment, preventing contamination, and providing structural

support.

Well Casing Pipe Materials

The material of the well casing pipe

directly affects its service life, corrosion resistance, and maintenance costs.

Common casing pipe materials include:

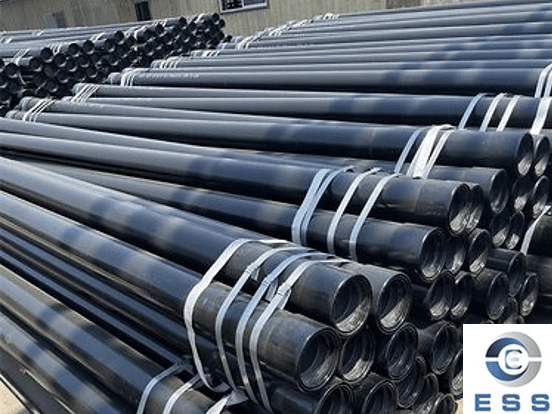

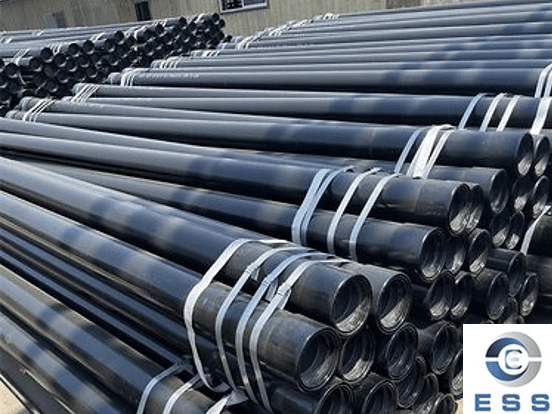

Steel casing pipe is the most traditional

and widely used type. It features high strength, good pressure resistance, and

resistance to mechanical impact.

Standard References: Common standards

include API

5CT, ASTM A53,

and ASTM

A106.

Advantages: Robust structure, suitable for

deep wells and complex geological environments.

Disadvantages: Susceptible to corrosion,

requiring regular protection and maintenance.

2. Plastic casing pipe (PVC or HDPE)

Plastic casing pipe is relatively new but

is becoming increasingly popular due to its high corrosion resistance.

Advantages: Corrosion resistant,

lightweight, and easy to install.

Disadvantages: Lower mechanical strength,

unsuitable for deep wells or areas with complex rock formations.

3. Concrete casing pipe

Rarely used in water wells today. Concrete

has high strength but is susceptible to certain types of damage.

Advantages: Low cost, resistant to chemical

corrosion.

Disadvantages: Prone to cracking, difficult

to repair, shorter service life.

Types of Well Casing Pipe

Well casing pipe comes in various types,

each with its specific purpose and suitability for different environmental

conditions. The most common types include:

1. Diverting casing pipe

This is the first layer of casing pipe

inserted into the well to prevent wellbore collapse and isolate surface water.

2. Surface casing pipe

It extends deeper underground, protecting

freshwater layers from contamination by isolating them from drilling fluid and

other deep formations.

3. Intermediate casing pipe

This type of casing pipe is used for

drilling very deep wells, especially in unstable geological formations. It

helps stabilize the wellbore and prevents any unwanted pressure interactions.

4. Production casing pipe

As the name suggests, this type of casing

pipe is installed in the production layer, the area where oil, natural gas, or

water is expected to be extracted.

5. Liner

The liner is typically used in deep wells.

It is a shorter section of casing pipe that does not extend to the surface but

is suspended from the preceding casing pipe and secured with cement.

Water Well Casing Pipe Damage

1. Corrosion

One of the most common problems with steel casing

pipe. Factors contributing to corrosion include: water pH, the presence of

certain chemicals, electric current, etc.

Corrosion weakens the casing pipe, leading

to leaks and ultimately structural damage.

2. Collapse and rupture

External pressure, such as pressure from

soil or underground movement, can cause casing pipe collapse.

Casing pipe rupture leads to water

contamination and a drop in water pressure, affecting the well's production

performance.

3. Joints and connections

Casing pipe connections are particularly

prone to problems. Over time, cracks or gaps may develop at these joints,

allowing impurities to enter and contaminate the water supply system.

Assessing the Degree of Casing Pipe

Damage

The following conditions may indicate a

problem with your well casing pipe:

1. Sediment in the water

If you notice an increase in sand, mud, or

other sediment in the water, your casing pipe may be damaged.

2. Drop in water pressure

A sudden or gradual drop in water pressure

may indicate a leak in the casing pipe.

3. Changes in water quality

Changes in the taste, odor, or color of the

water may indicate that contaminants are entering the water through a ruptured

pipe.

4. Visible damage

In some cases, you may see visible damage

to the casing pipe, such as dents, displacement, or breaks.

Well Casing Pipe Repair

Once the extent of the damage is

determined, repairs must be carried out immediately. Casing pipe repair methods

vary depending on the type and severity of the problem:

1. Corrosion mitigation

For corroded steel casing pipe, several

methods can be used to mitigate the damage:

Cathodic Protection: This technique

involves applying an electric current to the casing pipe to prevent oxidation

processes that lead to corrosion.

Coating: A special coating can be applied

to the outer surface of the casing pipe to protect it from the effects of the

external environment.

2. Repairing cracks and leaks

For cracked or leaking concrete or plastic casing

pipe, sealant compounds or patches can be used to restore the casing pipe's

integrity.

3. Reinforcement and Replacement

If the damage is severe, reinforcement or

complete replacement of part of the casing pipe may be necessary. Specialized

equipment and techniques are essential for this.

Preventive Measures for Well Casing Pipe

Damage

Taking protective measures can extend the

life of the casing pipe and reduce maintenance needs:

1. Routine inspections

Regular inspections by qualified

professionals can detect minor problems early, preventing them from escalating

into major issues that result in costly repairs or reduced well performance.

2. Water quality control

Some preventative maintenance measures

include treating well water with products designed to stabilize pH or using

sacrificial anodes to prevent corrosion.

3. Protecting joints

Regular maintenance and inspection of

joints and connections to ensure they remain strong and free of wear is highly

beneficial for protecting the well casing pipe.

4. Professional intervention

While some well-related tasks can be

performed DIY, the repair and maintenance of well casing pipe is best left to

professionals. Having experts familiar with local geology and water quality is

crucial to ensuring your well is in optimal condition.

5. Choosing the right professionals

Seek out OCTG pipe suppliers with a proven track record, necessary certifications, and an

excellent reputation. Local knowledge and experience are essential for

diagnosing specific problems in your area.

FAQ

1. How often should well casing pipe be

inspected?

Civilian wells: Inspect every 1–2 years.

Industrial or deep wells: Annually,

focusing on corrosion, current, and structural integrity.

2. What is the typical lifespan of well casing

pipe?

Steel casing pipe can last 30–50 years with proper protection;

Plastic casing pipe approximately 20–30 years;

Concrete casing pipe generally does not

exceed 20 years.

Summary

Well casing pipe is an indispensable but

often overlooked component of a well system. Understanding its structure,

common problems, and maintenance points not only ensures a long-term stable

water supply but also significantly reduces later maintenance costs.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.