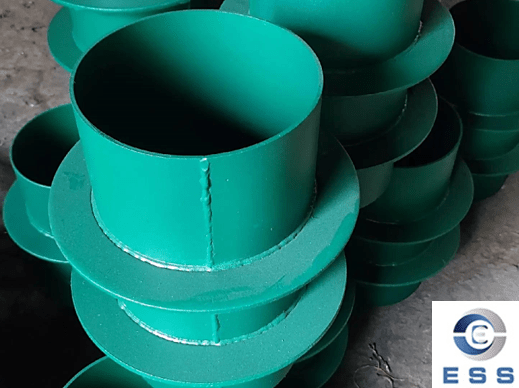

Casing Pipe Classification and Weight Summary

Casing pipe is a critical component widely

used in construction, petrochemical, power generation, and other fields. Its

weight varies depending on the material, specification, and length.

Understanding casing pipe weight is crucial for ensuring project safety,

controlling costs, and optimizing design plans.

Casing Pipe Classifications and Models

1. Oil Casing Pipe

Also known as steel

casing pipe, it can be classified as J55,

K55, N80,

and L80, depending on wall thickness and model.

2. Large-Diameter Casing Pipe

Depending on wall thickness and diameter,

it can be classified as large-diameter, extra-large-diameter, and

extra-thick-wall casing pipe.

Depending on the material and processing

method, it can be classified as standard drill pipe casing pipe and non-wear

drill pipe casing pipe.

Factors Affecting Casing Pipe Weight

1. Material

Casing pipe density varies depending on the

material, so the weight of casing pipe of the same size can vary. Common casing

pipe materials include steel, copper, and aluminum.

2. Specifications

The diameter and wall thickness of the

casing pipe are key factors affecting its weight. Generally speaking, larger

diameters and thicker walls increase the weight.

3. Length

The length of the casing pipe also affects

its weight. For the same material and specifications, longer casing pipes tend

to weigh more.

Casing Pipe Weight Summary

1. Oil Casing Pipe Weight Summary

|

Model

|

Diameter (mm)

|

Wall Thickness (mm)

|

Weight (kg/m)

|

|

J55

|

60.32

|

5.54

|

12.2

|

|

K55

|

73.02

|

5.51

|

16.13

|

|

N80

|

88.9

|

6.45

|

24.84

|

|

L80

|

88.9

|

7.62

|

29.94

|

2. Large Diameter Casing Pipe Weight

Summary

|

Model

|

Diameter (mm)

|

Wall Thickness (mm)

|

Weight (kg/m)

|

|

Large Diameter Pipe

|

177.8

|

14.78

|

71.43

|

|

Extra Large Diameter Pipe

|

244.5

|

28.58

|

188.15

|

|

Extra Thick Wall Casing Pipe

|

267

|

36.53

|

254.42

|

3. Drill Pipe Casing Pipe Weight

Summary

|

Model

|

Diameter (mm)

|

Wall Thickness (mm)

|

Weight (kg/m)

|

|

Ordinary Drill Pipe Casing Pipe

|

60.3

|

4.83

|

8.94

|

|

Non-Wear Drill Pipe Casing Pipe

|

50.3

|

6.8

|

10.09

|

Notes

1. Impact of Casing Pipe Material on Weight

Different materials have different

densities, which affect weight to varying degrees. For example, steel and

copper casing pipe of the same size can have significantly different weights.

During engineering design, casing pipe materials should be carefully selected

to meet project requirements while controlling weight.

2. Impact of Casing Pipe Size and Quantity

Casing pipe size and quantity also

significantly impact weight. Large-diameter or long-length casing pipe will

weigh more. Furthermore, the number of casing pipes should be considered, as

weight increases with the number of casing pipes. During engineering design,

casing pipe size and quantity should be determined based on actual conditions

to control weight.

3. Ensuring Calculation Accuracy

The casing

pipe weight calculation formula is theoretical, and varying degrees of

accuracy will have varying effects on the results. Therefore, calculations

should be performed with the utmost precision and error reduction to ensure

accurate results.

Casing Pipe Selection

Casing pipe is widely used in various

downhole operations, including oil and gas operations, and is an essential

industrial material. When selecting casing pipe, consider the following:

1. Model Selection

Select the appropriate casing pipe model

based on operational needs.

2. Material Selection

Different operating scenarios and

requirements require different materials.

3. Wall Thickness Selection

Select the appropriate wall thickness based

on a comprehensive consideration of factors such as well depth, wellbore, and

operating environment to ensure casing pipe strength and safety.

4. Quality Inspection

Inspect the quality of casing pipe when

purchasing to avoid purchasing low-quality casing pipe.

Summary

This article focuses on the model,

diameter, wall thickness, material, and corresponding weight data for three

types of casing pipe: oil casing pipe, large-diameter casing pipe, and drill

pipe casing pipe. Casing pipe weight is a complex issue involving multiple

factors. By understanding the parameters and factors that affect casing pipe

weight, mastering the calculation method of casing pipe weight and paying

attention to its practical application value, we can better utilize this

important engineering component to provide strong support for various projects.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.