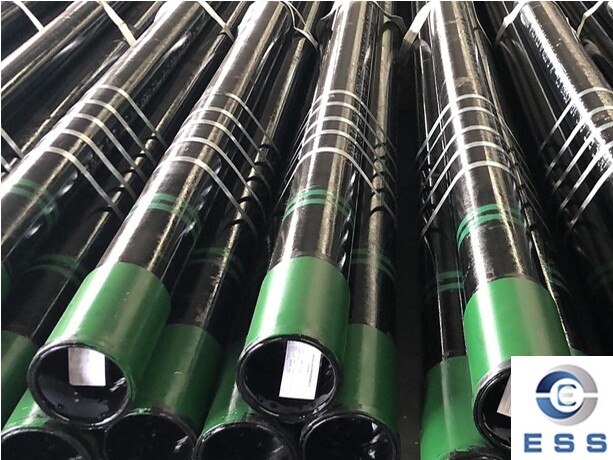

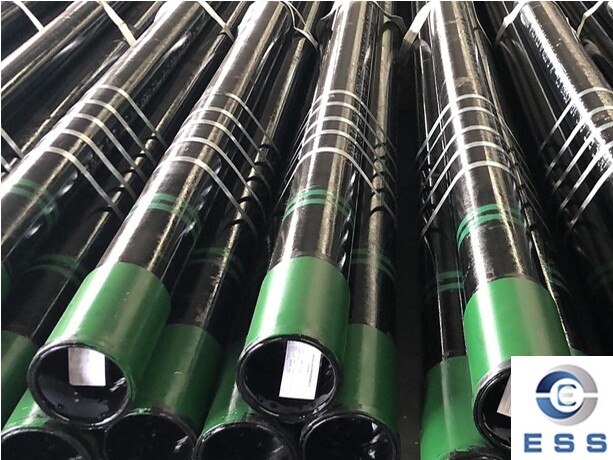

Oil pup joints,

especially API oil casing pup joints, have a wide range of application

scenarios in oil engineering. The following is a detailed summary of its

application scenarios:

Oil well drilling process

1. Providing a stable wellbore environment

During the oil drilling process, the first

short casing that is lowered into the wellbore is called a feed pup joint or

surface casing pipe.

Its main function is to provide a stable and safe wellbore environment for

subsequent drilling operations. At this time, pup joints made of seamless

pipe has become one of the common choices due to their good sealing and

anti-deformation capabilities.

2. Isolating the surface layer

Since the surface layer may contain

unstable or easily collapsed soil layers, the use of feed pup joints can

isolate these unstable layers and prevent safety accidents during drilling

operations.

3. Providing support and guidance

The feed pup joint provides a solid support

for subsequent drilling operations to prevent wellbore collapse or deformation.

At the same time, it also has a certain guiding function, which can ensure that

the drilling tools enter the ground in the correct direction.

Oil well production process

1. Oil well casing connection

API oil casing pup joints are widely used

in oil well casing connection to ensure the integrity and stability of the oil

well bore and prevent oil leakage and well bore damage.

2. Water injection pipe connection

In the water injection operation of the oil

field, the API oil casing pup joint can effectively connect the water injection

pipe and the well bore to improve the oil field's oil recovery efficiency.

3. Lifting pipe connection

API oil casing pup joints can also be used

for lifting pipe connection to ensure a tight connection between the lifting

pipe and the pump to avoid leakage and damage.

Other application scenarios

1. Oil and gas extraction

After the oil and gas wells are drilled and

cemented, oil pipes/pup joints can be placed in the oil layer casing to extract

oil and gas to the ground. Various pup joints in the OCTG pipe system, used in conjunction with oil pipes, can achieve efficient oil and gas

extraction.

2. Steam injection

In the process of heavy oil thermal

recovery, insulated tubings/pup

joints are required to input steam into the well.

3. Acidizing and fracturing

In order to increase the production of oil

and gas wells, it is necessary to carry out acidizing and fracturing operations

on the oil and gas layers. These media or solids are usually transported

through oil pipes/pup joints.

In summary, casing pup joints play a vital

role in petroleum engineering. They not only provide the necessary support and

protection for the drilling and production process, but also ensure the safe

and stable operation of the oil well. With the continuous development of

petroleum engineering and the continuous upgrading of technology, the

application scenarios and performance of casing pup joints will also be

continuously optimized and improved.

Read more: What Is The Minimum Length of Welded Pipe Pup Joints?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.