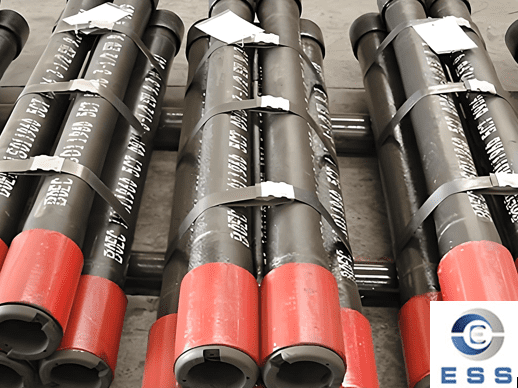

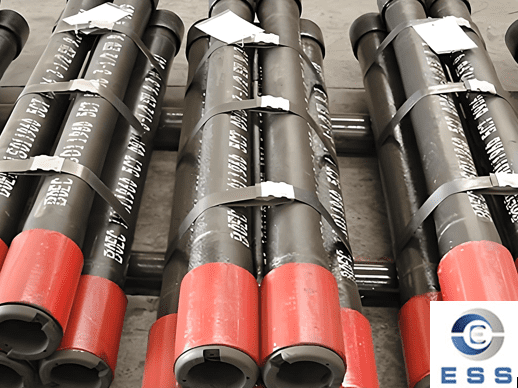

Introduction to The 27/8" L80 Tubing Pup

Joint

When assembling oil well tubing strings,

27/8-inch diameter pup joints, made of L80-grade steel, play an essential

connecting role. This often overlooked yet crucial component connects tubing to

precisely planned lengths. It ensures precise control of tubing lengths while

maintaining string stability and reliability in challenging well conditions.

What is A 27/8" L80 Tubing Pup

Joints?

The 27/8" L80 tubing pup joints are

short, 27/8-inch diameter tubing made of L80 steel. They feature threaded

connections at both ends for quick assembly with the tubing string.

1. Material characteristics of the L80 pup

joints

L80 steel has a minimum yield strength of

80,000 psi and offers high toughness, good ductility, wear resistance, and

excellent corrosion resistance.

2. Tubing pup joints thread type

Common thread types include EUE (External

Upset End) and NUE (Non-Upset End), which can be selected based on different

well conditions to ensure connection strength and sealing.

3. 27/8" pup joints length range

Common specifications include 2 ft, 3 ft, 4

ft, 6 ft, 8 ft, and 10 ft, allowing precise adjustment of tubing string length

to the wellbore configuration.

Advantages of the 27/8" L80 Tubing Pup

Joints

1. High strength

L80 steel has a minimum yield strength of

80,000 psi, capable of withstanding extremely high downhole pressures and loads

without failure.

2. Optimal toughness

L80 steel offers excellent ductility and

impact resistance, reducing the risk of cracking and failure during downhole

operations.

3. Wear resistance

The alloy composition increases hardness

and wear resistance, preventing tubing wear and leakage in abrasive well

conditions.

4. Corrosion resistance

L80 steel contains elements such as

chromium and molybdenum, making it resistant to corrosive media such as

hydrogen sulfide and carbon dioxide.

5. Durability

The combination of strength, wear

resistance, and corrosion resistance ensures the 27/8" L80 pup joint

provides reliable durability over many years of service.

6. Proven industry acceptance

After years of field experience, the

27/8" L80 pup joint has become a standard and reliable key component in

oil well construction.

Functions of the 27/8" L80 Tubing Pup

Joint

1. Connecting full-length tubing

Thread the pup joint between 30–40 feet of tubing to create a continuous tubing string that reaches

the target well depth. The pup joint can be increased or decreased in length to

achieve precise drilling.

2. Fine-tuning tubing string length

Finely adjusting the tubing string length

allows precise positioning of tubing, packers, logging tools, and other

equipment to the planned depth. This optimizes the positioning of downhole

components.

3. Compensating for thermal expansion

In high-temperature, deep wells, tubing

length can increase significantly due to thermal expansion. The 2 7/8-inch L80

tubing spool provides the necessary slight extension to maintain tubing string

integrity despite thermal effects.

4. Facilitating pulling and repair

operations

The spool piece facilitates disconnection

midway through the tubing string, allowing for quick replacement of damaged

tubing sections without removing the entire tubing string.

5. Adjusting wellhead equipment spacing

It creates precisely spaced wellheads by

connecting tubing at optimal distances between various components, such as the

tubing hanger, choke, and valves.

6. Adjustable sections available

The threaded ends on the 27/8" L80 pup

joint allow for easy assembly and disassembly of sections, allowing tubing

lengths to be adjusted as needed during initial installation and subsequent

workovers.

7. Connecting different pipe sections

They serve as connectors, connecting pipe

sections of different diameters or connection methods, creating a smooth

transition between mismatched sections.

27/8" L80 Technical Specifications

and Applications

1. Manufacturing standards

Strictly adhere to API 5CT standards, ensuring dimensional accuracy, thread quality, and mechanical

properties meet international standards.

2. Typical operating conditions

Suitable for complex environments such as

medium-depth wells, high-temperature wells, and sour wells.

FAQ

1. What are the differences between the L80

pup joint and the J55 and N80?

Compared to the J55, the L80 offers higher

strength and better corrosion resistance, making it suitable for more complex

operating conditions.

Compared to the N80, the L80 offers

superior resistance to hydrogen sulfide corrosion.

2. Are 27/8" L80 tubing pup joints

generally in stock? What is the lead time?

Most manufacturers keep standard lengths of

2–10 feet in stock. If a special length or thread type

is required, the typical lead time is 7–15 days.

3. Is the L80 pup joint suitable for sour

wells (H₂S environments)?

Yes, L80 material is specifically designed

to resist hydrogen sulfide corrosion and complies with NACE MR0175.

However, in highly corrosive or extreme

environments, a higher grade of material (such as Cr13 or P110) may be

required.

Summary

For assembling oil well tubing strings that

reach the target production zone with precise component spacing, the 27/8"

L80 tubing pup joint is the ideal choice. The 27/8" L80 tubing pup joint

is more than just an auxiliary component for connecting tubing; it is a key

factor in ensuring tubing string safety and efficient downhole operations. With

its high strength, excellent toughness, wear resistance and corrosion

resistance, it can adapt to the most complex well conditions and ensure the

safety and durability of oil well construction.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.