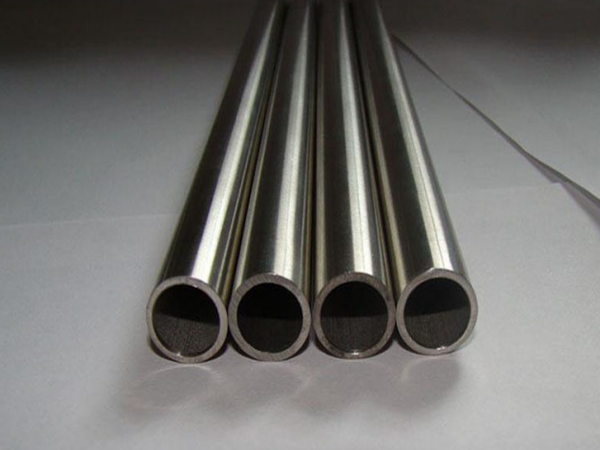

The code for stainless steel seamless

pipe is ASTM A312. This code is an international material standard for the

manufacture of stainless steel pipe, developed by the American Society for

Testing and Materials (ASTM). The ASTM A312, which covers austenitic and

ferritic stainless steel pipe, has been in existence since its first

publication in 1945.

History and Development of ASTM A312

ASTM A312 was first published in 1945 as the standard specification for the

manufacture of stainless steel seamless pipe. At that time, it only

covered austenitic and ferritic stainless steels. Since then, the scope of the ASTM

A312 has been expanded to include other stainless steel grades and types, such

as duplex, super duplex and ultra-high strength stainless steels. The latest

revision of the code includes new requirements on welding and testing and

additional classes for specific applications.

ASTM A312 stainless

steel seamless pipe: Requirements

The requirements for stainless steel seamless pipe specified in ASTM A312 are

designed to ensure that the pipes produced meet a wide variety of application

requirements. These include strength and ductility, corrosion resistance, and

maintenance requirements. In addition, ASTM A312 covers general requirements,

dimensions, dimensions tolerances, finish and testing requirements.

ASTM

A312 stainless steel seamless pipe: Material range and classification system

This

standard covers over 50 different grades of austenitic stainless steel,

primarily divided into the following series:

|

Grade

Series

|

Typical

Grades

|

Key

Properties

|

Applicable

Temperature Range

|

|

304 Series

|

TP304/TP304L/TP304H

|

General-purpose

austenitic stainless steel

|

-425°F to 1500°F

|

|

316 Series

|

TP316/TP316L/TP316H

|

Contains

molybdenum for improved corrosion resistance

|

-425°F to 1500°F

|

|

321/347

Series

|

TP321/TP347

|

Stabilized

with titanium or niobium

|

Intergranular

corrosion resistance

|

|

High-Temperature

H Series

|

TP309H/TP310H

|

High

carbon content for excellent creep resistance

|

high-temperature

service >1000°F

|

|

Special

Alloys

|

N08367/Alloy

20

|

Highly

alloyed for strong corrosion resistance

|

Extreme

corrosive environments

|

ASTM

A312 stainless steel seamless pipe: Manufacturing process and technical

requirements

1. Manufacturing

Methods

The

standard specifies three manufacturing processes: Seamless pipe (SMLS) uses a non-welding process; Welded pipe (WLD) uses an automatic welding process without the addition of

filler metal; and Heavy Cold Worked Pipe (HCW) requires cold working with a

minimum thickness reduction of 35%.

2. Heat

Treatment Requirements

All

steel pipe must be supplied in the heat-treated state. Heat treatment

temperature requirements vary by grade:

|

Material

Type

|

Heat

Treatment Temperature

|

Cooling

Method

|

Special

Requirements

|

|

Conventional

Austenitic Steel

|

≥1900°F

(1040°C)

|

Water

quench or rapid cooling

|

Prevent

carbide re-precipitation

|

|

H-Series

Grades

|

1900-2000°F

|

Water

quench or rapid cooling

|

Grain

size requirement: Grade 6-7 or coarser

|

|

Special

Alloys

|

1700-2280°F

|

Water

quench or rapid cooling

|

Adjusted

based on alloy composition

|

ASTM

A312 stainless steel seamless pipe: Key points for chemical composition control

The

standard has strict regulations on chemical composition.

Key

element control includes:

Carbon

content control: L series requires a carbon content of ≤0.035%, H series requires 0.04-0.10%

Stabilizing

elements: 321 contains titanium, 347/348 contains niobium, and Ti ≥ 5 × (C + N) or Nb ≥ 10 × C is required

Molybdenum:

316 series contains 2-3% molybdenum to improve pitting corrosion resistance

Nitrogen:

N series uses nitrogen to improve strength

ASTM

A312 stainless steel seamless pipe: Mechanical performance requirements

When

specifying ASTM A312 stainless steel pipe, it is important to consider strength

requirements. The appropriate strength requirements are stated in the ASTM A312

based on the intended application of the pipe. For instance, stainless steel

pipes used for pressure vessels should be able to withstand high pressures.

On the

other hand, stainless steel pipes used for general piping should allow for some

flexibility in order to maintain their integrity during normal operation.

Additionally, ASTM A312 requires that all pipe be ductile enough to handle

mechanical loading, thermal cycling and vibration without fracturing or losing

their integrity.

The

standard specifies tensile property requirements for different grades,

primarily divided into three strength grades:

|

Strength

Grade

|

Minimum

Tensile Strength

|

Minimum

Yield Strength

|

Typical

Grades

|

|

Standard

Strength

|

75

ksi (515 MPa)

|

30

ksi (205 MPa)

|

TP304,

TP316

|

|

High

Strength

|

80-95

ksi (550-655 MPa)

|

35-45

ksi (240-310 MPa)

|

TP304N,

S31254

|

|

Ultra-High

Strength

|

100-115

ksi (690-795 MPa)

|

50-62

ksi (345-430 MPa)

|

S31266,

S34565

|

ASTM

A312 stainless steel seamless pipe: Corrosion resistance

The ASTM A312 also specifies the corrosion resistance properties of the

stainless steel pipe. The most common corrosion resistance properties for

stainless steel pipe are chromium, nickel and molybdenum, which provide

resistance to many forms of corrosion, including pitting, crevice corrosion and

stress corrosion cracking. Additionally, the ASTM A312 specifies minimum

corrosion resistance requirements based on the intended application of the

pipe.

ASTM

A312 stainless steel seamless pipe: Testing and quality assurance

1.

Nondestructive Testing Requirements

Each

steel pipe must undergo hydrostatic testing or nondestructive electrical

testing (eddy current or ultrasonic). For pipe NPS 10 and above, the

hydrostatic testing requirement may be waived with the agreement of the

manufacturer and purchaser, but the letters "NH" must be included in

the marking.

2.

Intergranular Corrosion Testing

The

standard refers to ASTM A262 Practice E for intergranular corrosion testing.

Low-carbon and stabilized grades require testing under sensitized conditions;

other grades are tested in the as-delivered condition.

3.

Cryogenic Service Applications

The

standard specifically addresses cryogenic service applications: When the impact

test criteria are 15 ft·lbf energy absorption or 15

mils lateral expansion, certain austenitic stainless steel grades (such as

TP304, TP304L, and TP347) are accepted by the ASME Pressure Vessel Code at

temperatures as low as -425°F without impact testing.

ASTM

A312 stainless steel seamless pipe: Maintenance requirements

Maintenance requirements in the ASTM A312 are mainly related to keeping the

quality of the pipe consistent over time. This includes regular inspection and

testing so that the pipe is free from defects and remains safe and reliable in

its intended application. The ASTM A312 also recommends certain maintenance

practices, such as regular cleaning and lubrication, to ensure that the pipe

remains in good condition.

Conclusion

In

conclusion, the code for stainless steel seamless pipe is ASTM A312. This code

sets out the specifications for the manufacture of stainless steel pipe and

outlines requirements for strength and ductility, corrosion resistance and

maintenance, etc. The ASTM A312 also contains recommendations for maintenance

practices to keep the pipe in good condition over time.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.