The API standard for seamless casing pipe is

mainly API Spec 5CT. Its main contents are as follows:

Range of application

It specifies the technical delivery

conditions for steel pipes (casing pipe, tubing and pup joints),

coupling materials and accessory materials, and establishes requirements for

three product specification levels (PSL-1, PSL-2, PSL-3). It is applicable to

seamless casing pipe with short round threaded casing pipe (STC), long round

threaded casing pipe (LC), partial trapezoidal threaded casing pipe (BC),

special clearance casing pipe (XC), flat tubing (NU), thickened tubing (EU),

integral joint tubing (IJ) and other connection forms according to API Spec 5B.

Dimension requirements

1. Outer diameter: usually ranges from

6.0mm-219.0mm.

2. Wall thickness: 1.0mm-30mm.

3. Length: maximum length 12000mm.

Steel grade and chemical composition

1. J55

C content 0.34-0.39, Si content 0.20-0.35,

Mn content 1.25-1.50, P≤0.020, S≤0.015, Cr≤0.15, Ni≤0.20,

Cu≤0.20, Als≤0.020.

2. K55

C content 0.34-0.39, Si content 0.20-0.35,

Mn content 1.25-1.50, P≤0.020, S≤0.015, Cr≤0.15, Ni≤0.20,

Cu≤0.20, Als≤0.020.

3. N80

C content 0.34-0.38, Si content 0.20-0.35,

Mn content 1.45-1.70, P≤0.020, S≤0.015, Cr≤0.15, V content 0.11-0.16, Als≤0.020.

4. L80

C content 0.15-0.22, Si≤1.00, Mn content 0.25-1.00, P≤0.020, S≤0.010, Cr content 12.0-14.0, Ni≤0.20, Cu≤0.20, Als≤0.020.

5. P110

C content 0.26-0.35, Si content 0.17-0.37,

Mn content 0.40-0.70, P≤0.020, S≤0.010, Cr content 0.80-1.10, Ni≤0.20, Cu≤0.20, Mo content 0.15-0.25, V content 0.08, Als≤0.020.

Mechanical properties

1. J55: yield strength 379-552MPa, tensile

strength ≥517MPa.

2. K55: yield strength ≥655MPa, tensile strength ≥517MPa.

3. N80: yield strength 552-758MPa, tensile

strength ≥689MPa.

4. L80: yield strength 552-655MPa, tensile

strength ≥655MPa.

5. P110: yield strength 758-965MPa, tensile

strength ≥862Mpa.

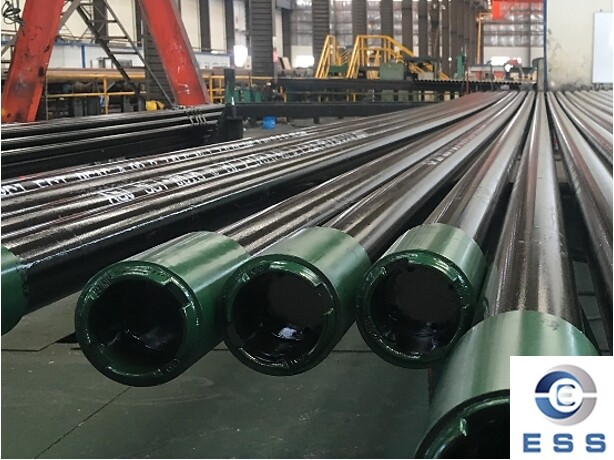

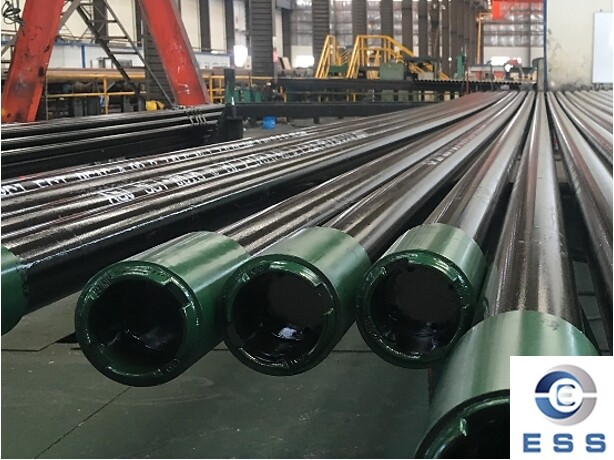

Surface requirements

1. Surface roughness: it should meet

international standards and be kept within a specific range to ensure its

sealing and lubrication properties.

2. Surface cleanliness: the surface should

be clean and free of impurities, and there should be no obvious oxide scale,

rust and stains.

3. Surface coating: if it is necessary to

apply a coating or coating on the surface of the steel pipe casing pipe, it

should meet the relevant standards and ensure the adhesion and durability of

the coating.

4. Surface hardness: the hardness of the

surface should meet customer needs and be able to resist corrosion and wear in

the external environment.

Summary

In short, the API standard guarantees the

quality and safety of seamless casing pipe and promotes industry collaboration.

Only by following it can casing pipe help various industries and promote

industrial development.

Read more: Specifications and dimensions of oil casing

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.