Use and installation of casing pipe

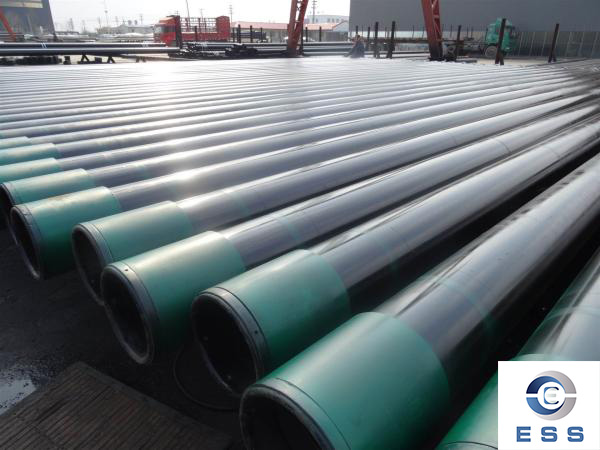

Use of casing pipe

Casing pipe is a commonly used device in engineering and construction to protect pipelines, cables and other equipment. It is widely used in industries such as oil, gas, electricity, and communications. The following are some tips for using casing pipe to help you use and install casing pipe correctly.

1. Choose the appropriate casing material and specification

The choice of casing pipe material depends on different application scenarios. Generally speaking, common casing materials include steel, plastic, aluminum, and stainless steel. You need to choose the appropriate casing material and specification based on factors such as environmental conditions, usage requirements, and financial budget. Size selection: The size of the steel pipe casing should match the diameter of the steel pipe, otherwise it will affect the protective effect of the casing.

2. Reasonable planning of casing path

Before installing the casing, you should reasonably plan the path of the casing to ensure that the casing will not suffer excessive pressure or distortion in a fixed position and length. When planning the path, try to avoid other pipelines, equipment, or narrow spaces to ensure the safety and reliability of the casing.

3. Prepare necessary equipment and tools

Before installing the casing, you need to prepare necessary equipment and tools, such as cable clamps, connectors, casing cutters, pliers, and screwdrivers. These tools and equipment will help you better install and connect the casing.

4. Ensure that the casing is firmly connected

When installing the casing, ensure that the casing is firmly and reliably connected. For threaded casing, use an appropriate wrench to tighten. For welded casing, use appropriate welding processes and equipment to ensure that the welding quality meets the standard requirements.

5. Perform necessary casing protection

The casing may be affected by the external environment and physical forces during use, so necessary casing protection is required. The casing is a moisture-proof and corrosion-resistant device, so during the installation process, pay attention to the humidity and temperature conditions, and do not let the casing be affected by moisture, acid and alkali. For example, on the casing exposed to harsh environments, anti-corrosion treatment should be performed to extend the service life of the casing. On the casing that is susceptible to mechanical or pressure effects, anti-collision protection devices or mounting brackets should be used to ensure that the casing is not damaged.

6. Regularly inspect and maintain the casing

The casing will be affected by wear, aging, and damage after a period of use. Therefore, regular inspection and maintenance of the casing is essential. You should regularly check the appearance and connection status of the casing, as well as wash and clean the impurities and contaminants inside the casing. If the casing is found to be damaged or loose, it should be replaced in time. If any problems are found, repair measures should be taken in time to ensure the normal operation of the casing.

7. Pay attention to the safe use of the casing

When using the casing, you should pay attention to safety issues. First, make sure that the load and working pressure of the casing do not exceed its rated value. Secondly, during the installation and removal of the casing, appropriate tools and methods should be used to prevent accidents caused by operating errors. In addition, you should strictly abide by the relevant safety operating procedures and standards, pay attention to prevent safety problems that may be caused by scratches, cutting, etc., to ensure the safe use of the casing.

(1) Remove dirt: Use tools such as wire brushes to remove dirt on the surface of the steel pipe.

(2) Spray primer: Apply a layer of primer on the clean surface of the steel pipe to enhance adhesion and prevent the steel pipe from rusting.

(3) Casing installation: Put the steel pipe on the surface of the steel pipe and evenly clamp it on the steel pipe. Special tools can be used to compact the air between the casing and the surface of the steel pipe to enhance the protection effect.

8. Use environment

Under different environmental conditions, choose steel pipe casing of suitable materials and models to ensure the service life and protection effect of the casing.

Installation of the casing pipe

The installation method of the casing mainly includes the following steps

1. Determine the installation location:

The area and specific location where the casing needs to be installed need to be determined according to the project needs. This includes considering the type of casing (such as rigid casing, flexible waterproof casing, etc.) and their specific uses.

(1) Confirm the model and size of the casing to ensure that it matches the cables and pipelines to be protected, and select high-quality casing that meets national standards.

(2) Clean the installation location to ensure that the installation location is clean and tidy, without obstacles such as garbage and debris, so as to facilitate the normal installation of the casing.

(3) Prepare the required tools and materials, such as wrenches, scissors, steel wire, steel bars, etc., to ensure that the equipment and tools required during the installation process are complete.

2. Measurement and marking: Determine the size and installation location of the casing according to the construction drawings and specifications. Use a ruler to measure and mark the location where the hole needs to be drilled.

3. Drilling: Use a drilling tool to drill holes at the marked location. The hole diameter and depth must match the size of the casing.Cleaning the hole: Use a rag or compressed air to remove dust and debris in the hole to ensure the cleanliness of the installation surface.

4. Assemble the casing: hoist the casing to the installation location, or directly place the casing in the installation location by hand, and ensure that the casing is straight. Assemble the casing with the pipe to ensure that the assembly is firm and tight. For flexible waterproof casing, it is also necessary to check whether the bolt holes of the flange are unobstructed to prevent concrete clogging.

5. Check the sealing: apply an appropriate amount of water or other sealing materials on the assembled casing, check the sealing between it and the pipe, and ensure that there is no leakage. At the casing connection, use special scissors to regularize the size of the casing and use sealant to seal it to prevent rainwater from seeping in.

6. Install the fixings: select suitable fixings such as nuts, bolts, etc. according to the model and specifications of the casing. Install the fixings on the casing to ensure that it is firm and stable.

7. Connect the pipeline: use a special wrench to align the thread of the casing with the pipe mouth at a 45-degree angle, and rotate the thread to the left so that the casing is tightly connected to the pipe mouth. Connect the casing with the pipeline to ensure that the connection is firm and tight to avoid gaps or leakage.

8. Adjust the position: Check whether the position of the casing and the seamless pipe connection is correct. If necessary, use the adjustment piece to adjust it.

9. Fix the casing: According to the actual situation or requirements, use the fixing piece/wire to firmly fix the sleeve on the pipe to ensure that it will not loosen or fall off and is firmly installed.

10. Check the fixing effect: Check the fixing effect of the sleeve to ensure that it is firmly fixed on the pipe to avoid leakage.

Precautions for casing installation

1. Before installation, check the environment and use conditions, evaluate the installation difficulty and safety risks, and take necessary safety protection measures.

2. Choose high-quality casing that meet national standards and technical standards to prevent the use of inferior products.

3. During the installation process, pay attention to the tightness of the casing joint to avoid looseness and water leakage.

4. Avoid corners or bends at the joints of the casing to ensure the smoothness and ventilation of the casing.

5. After installing the sleeve, check and maintain the casing in time, and carry out necessary cleaning and repairs in time.

Summary

The use skills of casing include selecting appropriate casing materials and specifications, rationally planning casing paths, preparing necessary equipment and tools, ensuring that the connection of casing is firm and reliable, performing necessary casing protection, regularly inspecting and maintaining casing, and paying attention to the safe use of casing. By using and installing casing according to the correct use skills, the service life and reliability of casing can be improved, and the effect and safety of engineering and construction can be ensured.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.