Storage method of hydraulic tubes

The standard of fluid pipes in hydraulic systems is close to GB3639-83 in China.

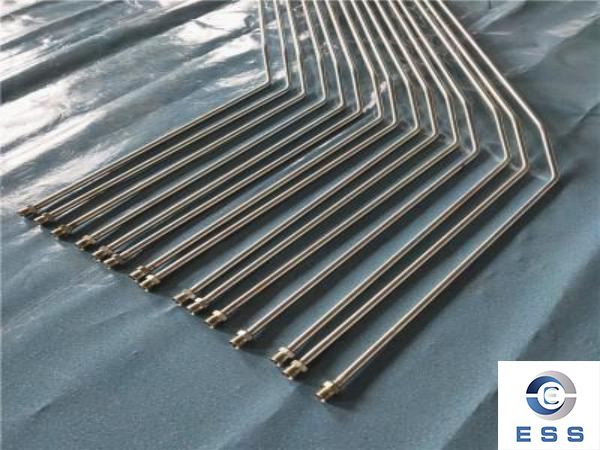

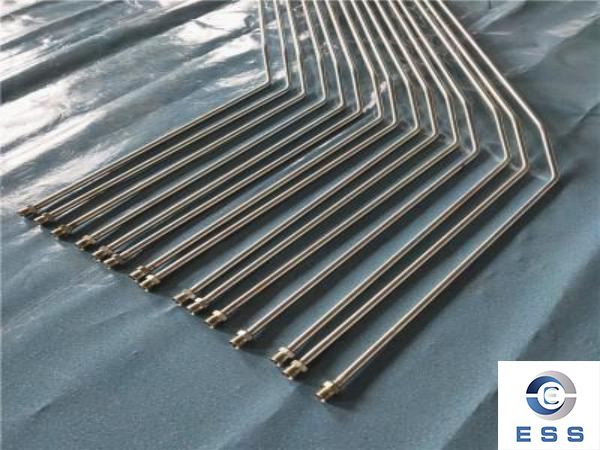

Introduction to hydraulic tubes: Cold-drawn or cold-rolled precision seamless pipes with high dimensional accuracy and good surface finish for hydraulic equipment. Precision seamless pipes are used to manufacture mechanical structures or hydraulic equipment, etc. Precision tubes are a kind of high-precision seamless pipes after cold drawing or cold rolling. Due to the advantages of no oxide layer on the inner and outer walls of precision steel pipes, no leakage under high pressure, high precision, high finish, no deformation after cold bending, no cracks after expansion and flattening, they are mainly used to produce pneumatic or hydraulic products.

Storage method of hydraulic tubes

Environmental requirements

1. The storage environment of hydraulic tubes should be kept in a dry, clean, ventilated and suitable place, and the temperature should not be too high or too low.

2. The relative humidity should be less than 80%, the humidity of the storage location should be kept between -15°C and 40°C, and the hydraulic tubes should be kept away from direct sunlight and water. For example, in summer, they can be placed in an air-conditioned room to prevent long-term high temperature exposure to avoid aging and cracking. If it is necessary to place it in the open air, sun protection and rain protection measures should be taken, and grooves should be set up to drain water in time to prevent water accumulation.

3. Hydraulic tubes placed in warehouses, storehouses, cabinets and other indoor places must be kept clean and dry to prevent dust and water vapor from entering the pipes, causing corrosion and rust.

4. Both ends of the hydraulic tube must be tightly sealed to prevent debris from entering the hydraulic pipes.

5. It must not come into contact with acids, alkalis, oils, organic solvents or other corrosive liquids or gases, and should be 1m away from heat sources.

Rust prevention methods

1. There are many rust prevention methods for hydraulic tubes, among which paint, spraying and other methods are the most common. When using these methods, it should be ensured that the surface of the hydraulic tube is cleaned and treated as necessary to ensure the rust prevention effect.

2. For hydraulic tubes stored for a long time, it is recommended to adopt a passivation protection method, that is, to plate a layer of zinc or chromium metal on the surface of the hydraulic steel tube to prevent the surface of the steel pipe from contacting with the ambient oxygen and producing an oxidation reaction, thereby achieving environmental protection.

Stacking location

1. It is strictly forbidden to stack heavy objects on the pipe body to prevent external force extrusion and damage. Avoid mechanical shock, extrusion and friction of hydraulic tubes;

2. If hydraulic tubes need to be temporarily stored in the open air, the site must be flat, the pipes must be laid flat, and the top cover must be covered. Heavy objects must not be stacked, and they must not come into contact with heat sources.

3. To prevent the hydraulic tubes from being compressed and deformed during storage, the stacking height should not be too high, and the height should not exceed 1.5mm; and the hydraulic tubes often need to be "knocked" during storage, not less than once every quarter.

4. Store in a loose state as much as possible. Generally, hydraulic tubes with an inner diameter of less than 76mm can be stored in coils.

5. Hydraulic tubes of different types and specifications are stored separately. Do not overlap or hang them to avoid confusion and misuse.

Other precautions

1. Hydraulic tubes should be carefully inspected before storage. If any defects or damage are found, they should be handled in time to prevent them from affecting the next step of use.

2. Hydraulic tubes should be handled with care during transportation and storage to avoid physical damage such as collision and falling.

3. The storage time of hydraulic tubes should not be too long, and should not exceed two years. They should be used before storage to avoid affecting the quality of the hydraulic tubes due to long storage time. Regular inspections should be carried out according to actual conditions and necessary maintenance and anti-corrosion treatment should be carried out.

Summary

Hydraulic tube is a widely used pipe material with very strict storage requirements. Only by strictly complying with the storage environment requirements, adopting necessary anti-rust methods and paying attention to storage details can the hydraulic tube be kept in good use and provide reliable support for the production and construction of various industries.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.