Seamless hydraulic tube for accuracy machinery

In the realm of accuracy machinery, where precision, effectiveness, and dependability are paramount, even the smallest elements play a pivotal role in attaining exceptional performance. Amongst these components, seamless hydraulic tubes stand out as an important backbone, enabling the flawless operation of elaborate systems that power industries varying from aerospace and vehicle to producing and robotics. In this article, we dig deep into the world of seamless hydraulic tubes, revealing their significance, making processes, applications, and the advanced improvements that continue to form the landscape of modern-day engineering.

Comprehending the Significance of seamless hydraulic tubes

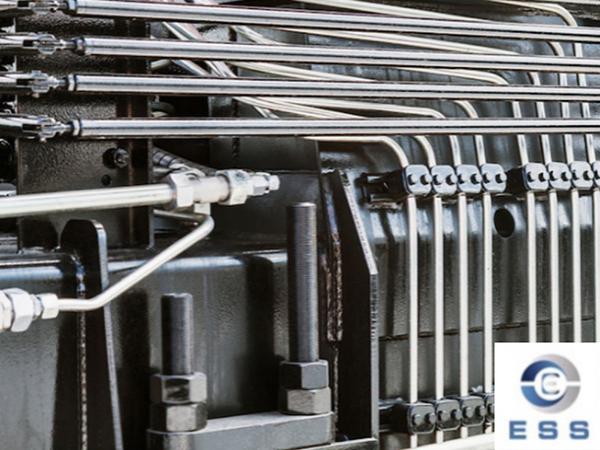

Seamless hydraulic tubes are a type of tubing created to carry hydraulic fluid within a system. Hydraulic systems, which depend on the transfer of pressurized fluid to create mechanical force and movement, form the basis of different precision machinery applications. These systems require high levels of accuracy, performance, and security. seamless hydraulic tubes play a crucial function in making sure that these demands are met.

The "seamless" element of these tubes describes their production process, which includes forming tubes with no welded joints. This particular provides numerous benefits over bonded tubes, including improved strength, enhanced uniformity, and lowered threat of leakages. These attributes are important for accuracy equipment, where even the tiniest flaw can cause catastrophic failures or diminished performance.

Manufacturing Process

The production procedure of seamless hydraulic tubes is a complex and elaborate treatment that includes multiple phases to ensure the highest quality and consistency. The procedure begins with the choice of suitable materials, which are often high-strength alloys created to withstand the pressures and forces within hydraulic systems. Common materials consist of stainless-steel, carbon steel, and different alloys.

1. Tube Development: The initial step includes piercing a solid round billet to develop a hollow tube. This process is performed through different strategies such as extrusion, rotary piercing, or the Mannesmann procedure. The result is a smooth tube with precise measurements and internal surface areas.

2. Cold Drawing: After television is pierced, it goes through a series of cold illustration procedures. This involves pulling television through a series of passes away to reduce its diameter and attain the preferred measurements. Cold drawing improves the tube's mechanical residential or commercial properties and surface finish, ensuring uniformity and strength.

3. Heat Treatment: Heat treatment is frequently applied to enhance television's mechanical homes. This action includes subjecting the tube to particular temperature level varieties and cooling processes to achieve the wanted hardness, tensile strength, and resistance to deterioration.

4. Completing and Evaluating: The final action involves ending up procedures such as cutting, straightening, and polishing to achieve the needed surface finish. Televisions are then subjected to extensive quality screening, consisting of non-destructive screening approaches like ultrasonic or eddy present screening, to determine any defects that might compromise performance.

Applications in Accuracy Equipment The applications of seamless hydraulic tubes in accuracy machinery are vast and differed. These tubes are found in systems that require exacting requirements, such as:

1. Aerospace Industry: From landing equipment systems to flight control systems, aerospace engineering relies greatly on hydraulic systems to make sure the safe and efficient operation of airplane. Seamless hydraulic tubes offer the reliability required to browse the skies.

2. Automotive Sector: In modern-day cars, hydraulic systems are accountable for functions like power steering, brake systems, and suspension. The precision and responsiveness of these systems are directly influenced by the quality of the hydraulic tubes utilized.

3. Production Equipment: In manufacturing environments, accuracy and effectiveness are critical. seamless hydraulic tubes are used in equipment used for metal forming, plastic injection molding, and other procedures that need precise control of force and motion

Conclusion

As developments in materials science, producing techniques, and clever technology continue to form the engineering landscape, seamless hydraulic tubes are progressing together with them. The combination of innovative products, precision manufacturing strategies, and innovative technologies is pressing the limits of what these simple tubes can attain, allowing even greater feats of precision and efficiency in the equipment that specifies our modern-day world.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.