Drill pipe is an indispensable tool in oil drilling operations. It is an important component connecting the drill bit and the drilling rig. It is an octg pipe.The manufacturing process of drill pipe mainly includes raw material preparation, processing and manufacturing, quality inspection and other links.

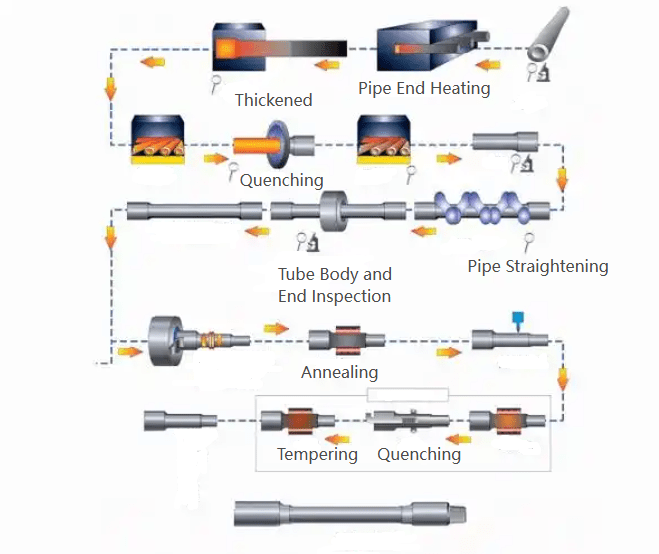

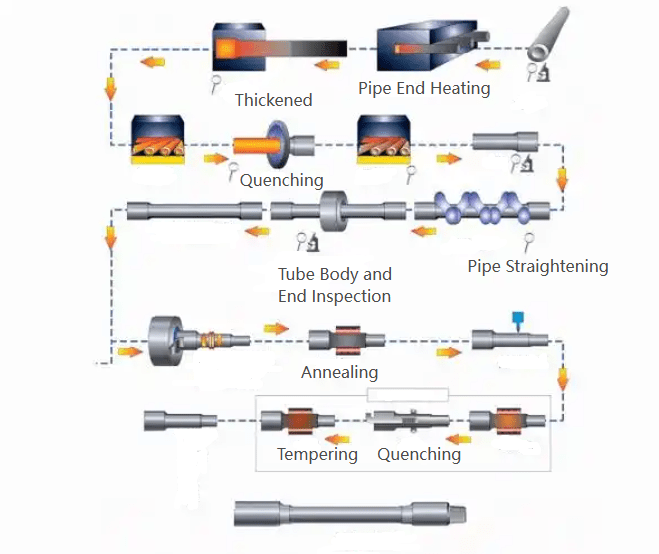

Drill pipe manufacturing process

1. Material selection

The main raw material of drill pipe is high-strength alloy steel pipe, and its material should meet the relevant standard requirements. When making drill pipe, it is necessary to use high-strength and corrosion-resistant alloy steel as raw material. Generally, G105 and S135 are commonly used. The procurement of raw materials should be strictly in accordance with the contract provisions to ensure the quality of materials, and check the information such as raw material manufacturer, batch number and material number to ensure the traceability of raw materials.

2. Cutting and chamfering

Cut the raw materials, cut the high-strength alloy steel pipe into the corresponding length and chamfer according to the design requirements. In this process, attention should be paid to the cutting accuracy and chamfer uniformity to ensure the straightness and dimensional accuracy of the drill pipe. Cutting should be carried out under heating to avoid cracks and deformation.

3. Rolling

The material is rolled and rolled into different models and specifications as needed. In this process, it is necessary to pay attention to controlling the rolling effect to provide a good foundation for subsequent processing and use.

4. Heat treatment

Heat treatment is a relatively important step in the production of drill pipes. It is mainly to improve the strength and durability of steel by adjusting the internal organization and structure of steel. According to the material and requirements, heat treatment processes such as quenching and tempering are carried out. During heat treatment, factors such as temperature, insulation time, and cooling rate need to be strictly controlled.

5. End making

End making includes two links: one is to make the end head; the other is to make the thread. Turning, milling, drilling and other processes are required on the machine tool.

6. Assembly

Assemble the two ends and the pipe body together, tighten the nuts and perform stiffness tests to ensure that the quality of the drill pipe meets the requirements.

7. Grinding

This process requires the use of high-precision processing equipment to repeatedly grind the drill pipe and control the process parameters to ensure surface finish and dimensional accuracy.

8. Quality inspection and painting

After the drill pipe is manufactured, it must be inspected and tested to ensure that its quality meets relevant standards and regulations. The main inspection items include strength, rigidity, dimensional accuracy, surface quality and other aspects; finally, spraying, anti-corrosion treatment and marking are carried out to improve the service life of the drill pipe.

Common manufacturing problems and solutions

1. Drill pipe bending

Focus on controlling the heat treatment and processing technology in production to prevent excessive deformation and stress. At the same time, the drill pipe should also be inspected, maintained and repaired regularly.

2. Drill pipe cracks

This is an important indicator of the quality of drill pipe production. It is necessary to strictly contr

ol factors such as material properties and heat treatment parameters, and conduct quality inspection and maintenance in time.

3. The surface finish of the drill pipe is not good

This problem requires focusing on the accuracy of the processing technology and equipment, and improving the processing accuracy and process control level.

Common drill pipe machining methods

1. Drilling

Drilling is one of the most common

machining methods for drill pipes. In drilling, it's crucial to select

appropriate drill bits and cutting parameters to ensure accuracy and surface

quality.

2. Turning

Turning drill pipes requires tools such as

cutting tools and lathes. To ensure the quality and accuracy of the turned

surface, it's necessary to select appropriate lathes and cutting tools, and

master suitable cutting parameters.

3. Milling

Milling drill pipes requires tools such as

milling cutters and milling machines. To ensure the quality and accuracy of the

milled surface, it's necessary to select appropriate milling machines and

cutting tools, and master suitable cutting parameters.

Drill pipe quality inspection

Drill pipe quality inspection is a crucial

step in ensuring the safe and efficient operation of projects such as oil and

gas drilling. Here are some common drill pipe quality inspection methods:

1. Visual Inspection

Carefully observe the surface of the drill

pipe, checking for obvious defects such as cracks, dents, wear, or corrosion.

These defects may reduce the strength and durability of the drill pipe, and

even lead to breakage during use.

Ensure the thread shape and dimensions

conform to standards. The thread surface should be smooth, free of burrs,

cracks, or other damage. The quality of the thread connection directly affects

the reliability of the drill pipe connection; any defects may lead to loosening

or failure.

2. Dimensional measurement

Use professional measuring tools, such as

calipers and micrometers, to measure the diameter, length, and wall thickness

of the drill pipe. Dimensional deviations should be within the specified range;

otherwise, they may affect the drill pipe's fit accuracy and performance.

3. Measure the drill pipe's curvature

Place the drill pipe on a level platform

and use a ruler or measuring instrument to check the deviation between its two

ends. Excessive curvature will affect the drill pipe's guidance and stability

during drilling, increasing drilling risks.

4. Material performance testing

Conduct chemical composition analysis to

check if the chemical composition of the steel used in the drill pipe meets

standard requirements. Different drilling environments and operating conditions

have different requirements for the material properties of the drill pipe;

ensuring the accuracy of the chemical composition guarantees stable drill pipe

performance.

Perform mechanical property tests,

including tensile tests and impact tests. Tensile testing measures the yield

strength and tensile strength of drill pipe steel, while impact testing

evaluates the drill pipe's impact resistance under harsh conditions such as low

temperatures. These performance indicators directly relate to the drill pipe's

ability to withstand tensile, torque, and impact loads during drilling.

5. Flaw detection

Ultrasonic testing is a commonly used

method for drill pipe flaw detection. It detects internal defects by observing

the propagation and reflection of ultrasonic waves within the drill pipe. The

flaw detector emits ultrasonic waves and receives the reflected signals, using

the characteristics of the signals to determine the presence of defects such as

cracks and inclusions.

Magnetic particle testing is suitable for

detecting surface and near-surface defects such as cracks in drill pipes.

Magnetic powder is applied to the drill pipe surface, and magnetization creates

a leakage magnetic field at the defect. The magnetic powder is attracted to the

defect, revealing its location and shape.

5. Pressure resistance and sealing

performance testing

For drill pipes used in special conditions

such as high-pressure drilling, pressure resistance testing is required to

ensure their safety under high-pressure environments. Connect and seal the

drill pipe. Gradually increase the pressure using a pressurizing device,

observing whether the drill pipe can withstand the specified pressure without

leakage or rupture.

The sealing performance test mainly targets

the joints of the drill pipe, checking their sealing performance to prevent

leakage of drilling fluid or other media during drilling. A sealing test device

can be used to test the sealing performance of the joints.

Conclusion

The drill pipe manufacturing process is a complex processing and manufacturing process that requires multiple steps. Controlling the quality and process parameters of each step is very important to improve the service life and performance of the drill pipe. Only after strict control and inspection can drill pipe that meet the requirements be produced. At the same time, for common production problems, corresponding solutions need to be taken to ensure the quality and use effect of the drill pipe. Manufacturers should formulate a complete quality management system, strengthen the management of each link, and improve production efficiency and quality.

Read more: Size of Drill Pipe or How Many Types of Drill Pipe Threads Are There?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.