Precautions when welding square and rectangular tubes

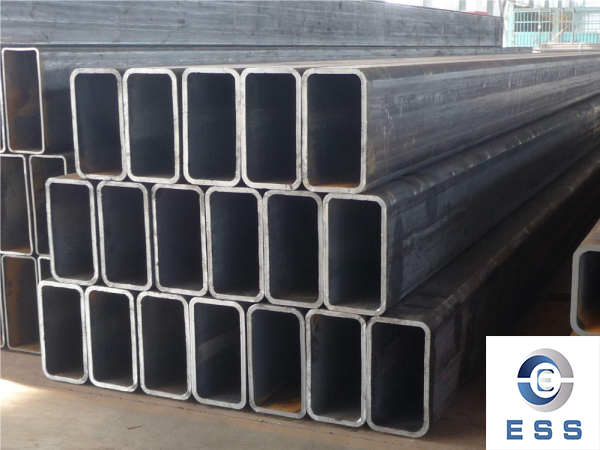

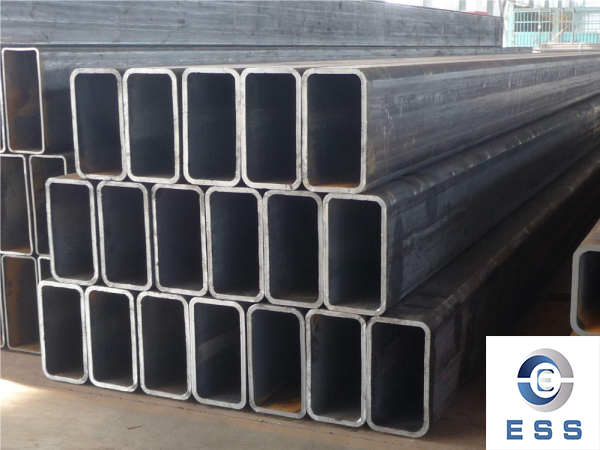

Square and rectangular tube is a name for square pipes and rectangular pipes, that is, steel pipes with equal and unequal side lengths. It is made of strip steel rolled through process treatment. Generally, the strip steel is unpacked, flattened, curled, and welded into a round tube, which is then rolled into a square tube and then cut to the required length.

Square and rectangular tubes are also known as square and rectangular cold-formed hollow sections, referred to as square tubes and rectangular tubes, and their codes are F and J respectively.

1. The allowable deviation of the wall thickness of square and rectangular pipes shall not exceed plus or minus 10% of the nominal wall thickness when the wall thickness is not greater than 10 mm. When the wall thickness is greater than 10 mm, it shall be plus or minus 8% of the wall thickness. Corner and weld areas Except wall thickness.

2. The usual delivery length of square and rectangular tubes is 4000mm-12000mm, with the majority being 6000mm and 12000mm. Square and rectangular pipes are allowed to be delivered in short length and non-fixed length products of not less than 2000mm, and can also be delivered in the form of interface pipes, but the purchaser should cut off the interface pipes when using them. The weight of short-length and non-fixed-length products shall not exceed 5% of the total delivery quantity. For square and rectangular pipes with a theoretical weight greater than 20kg/m, the weight shall not exceed 10% of the total delivery quantity.

3. The curvature of square and rectangular tubes shall not be greater than 2mm per meter, and the total curvature shall not be greater than 0.2% of the total length.

Uses of square and rectangular tubes

Application fields: Widely used in machinery manufacturing, construction industry, metallurgical industry, agricultural vehicles, agricultural greenhouses, automobile industry, railways, highway guardrails, container frames, furniture, decoration and steel structure fields.

Used in engineering construction, glass curtain walls, door and window decoration, steel structures, guardrails, machinery manufacturing, automobile manufacturing, home appliance manufacturing, shipbuilding, container manufacturing, electric power, agricultural construction, agricultural greenhouses, bicycle racks, motorcycle racks, shelves, fitness equipment, Leisure and travel products, steel furniture, various specifications of oil casing, oil pipes and pipeline pipes, water, gas, sewage, air, heating and other fluid transportation, fire protection and brackets, construction industry, etc.

When we welding square and rectangular pipes, we should pay attention to the following eight points:

1. Before igniting the welding spray gun for square and rectangular pipes, the air tightness of the air valves in all connected parts of the pipe should be checked. If there is air leakage, it must be repaired.

2. Ensure that all gas channels of the welding equipment are not contaminated with oil to prevent oxygen from burning and exploding when exposed to grease.

3. If backfire is found, the powder spray gun should immediately close the acetylene gas valve on the gun body, and the wire spray gun should immediately close the main valve, so that the backfire will be quickly extinguished in the gun. Wait a moment, then open the main valve, blow out the soot remaining in the gun, and then ignite it for use. Use a lighter when igniting, and do not use cigarette butts to ignite, otherwise it will easily burn your hands.

4. When the spray gun is out of use, it should be hung together with the hose or placed in a box to prevent dust and impurities from invading and affecting its use.

5. The injection and absorption performance of the welding equipment for square and rectangular pipes must be checked before use. During the inspection, connect the oxygen pipe, open the acetylene valve and the oxygen valve, and gently touch the acetylene inlet of the spray gun with your finger. If you feel a suction force, it means that the injection and suction are normal and you can use it. Otherwise, it is abnormal and should be inspected and repaired.

6. When welding square and rectangular pipes, it is strictly forbidden to block the spray gun nozzle with hands or other objects when the oxygen valve and acetylene valve are opened at the same time to prevent oxygen from flowing back and entering the acetylene generator.

7. It is strictly prohibited to place the burning spray gun on the ground or other objects. The nozzle must not be mated, otherwise it will easily explode or even "backfire" during use.

8. When welding square and rectangular pipes, the transmission parts should always be kept lubricated, and some thin grease of molybdenum disulfide can be added.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.