Precautions for installing rectangular pipe

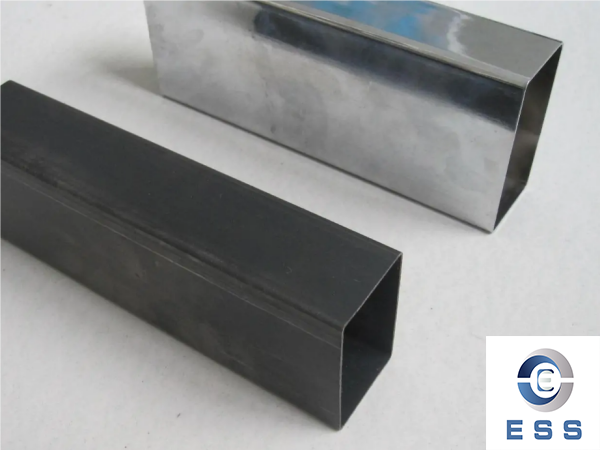

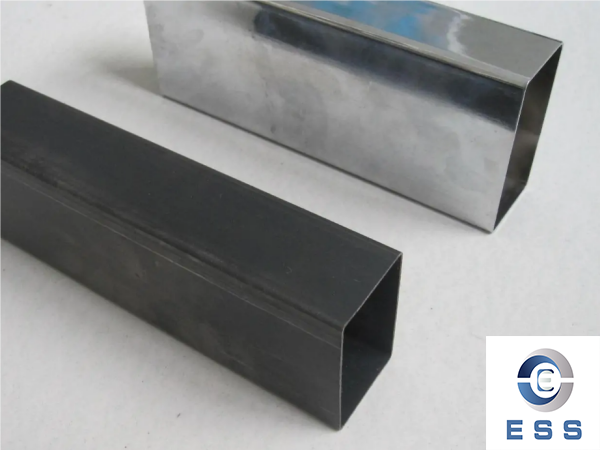

Basic concepts of rectangular tubes

Rectangular tube is a hollow square cross-section lightweight thin-walled steel tube, also known as steel cold-formed profile. It is a square section steel with a square cross-section shape and size made of Q235 hot-rolled or cold-rolled strip or coil as the base material, which is formed by cold bending and then high-frequency welding. In addition to the thickening of the wall thickness, the corner size and edge straightness of hot-rolled extra thick-walled square tubes reach or even exceed the level of resistance welded cold-formed square tubes.

Classification of rectangular tubes

Classification of rectangular pipes: Steel pipes are divided into seamless steel pipes and welded steel pipes (seamed pipes), hot-rolled seamless square pipes, cold-drawn seamless square pipes, extruded seamless square pipes, and welded square pipes.

Among them, welded square pipes are divided into:

1. According to the process - arc welded square tube, resistance welded square tube (high frequency, low frequency), gas welded square tube, furnace welded square tube;

2. According to the welding seam - straight seam welded square pipe, spiral welded square pipe.

The use of rectangular tubes

Construction, machinery manufacturing, steel construction projects, shipbuilding, solar power generation brackets, steel structure engineering, power engineering, power plants, agricultural and chemical machinery, glass curtain walls, automobile chassis, airports, etc.

Precautions for installing rectangular pipes

The usage rate of Q345 seamless rectangular pipe is very high, but generally the construction party will conduct a visual inspection of the pipes, pipe fittings, rubber rings, etc. before construction, and if any problems are found, they must abandon use.

1. Clean the Q345 seamless rectangular pipe mouth: remove and scrub all debris inside the socket.

2. Clean and apply the apron: Wipe off the adhesive on the apron, bend the apron into a "plum blossom shape" or figure 8 shape and install it into the socket groove, and press the entire apron with your hand, or Use a rubber hammer to pound firmly to ensure that all parts of the rubber ring are not warped or twisted, and are evenly stuck in the groove.

3. Apply lubricant to the outer surface of the socket and the rubber ring: Apply lubricant evenly to the inner surface of the rubber ring after the socket is installed. When applying lubricant to the outer surface of the socket, be sure to apply lubricant to the socket parts other than the socket line. Brush everything evenly.

4. Lowering the pipe: The Q345 seamless rectangular pipe should be lowered to the bottom of the tank according to the requirements of the lower pipe. The manual lowering method or the mechanical lowering method is usually used.

5. Install machinery and equipment: Install the prepared machinery and equipment in place. During installation, be careful not to contaminate the cleaned Q345 seamless rectangular pipe parts again.

6. Push up the Q345 seamless rectangular pipe to insert it into the socket: During installation, it is easier and smoother to insert the socket into the socket. First, put the socket into the socket and press the socket onto the rubber ring in the socket. Connect the wire rope and the inverted chain, and tighten the inverted chain; until the socket is fully inserted into the socket, there should be a gap of about 2mm between the socket and the socket. , and ensure that the distance from the outer edge of the socket to the rubber ring is consistent.

During the installation process, the axis lines of the fixed pipe and moving pipe must be in a straight line, otherwise the rubber ring will be easily pushed out, affecting the quality and speed of the installation. Q345 seamless rectangular pipes should be installed flat, and the Q345 seamless rectangular pipes should be in a straight line. Be careful when encountering an inclination angle. Align the interface connecting the Q345 seamless rectangular pipe with the socket. If the insertion resistance is too great, do not force the insertion to prevent the rubber ring from twisting. Vegetable oil should be used as the lubricant for the rubber ring; in cold winter, the rubber ring can be preheated with hot water to reduce the hardness and facilitate quick installation.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.