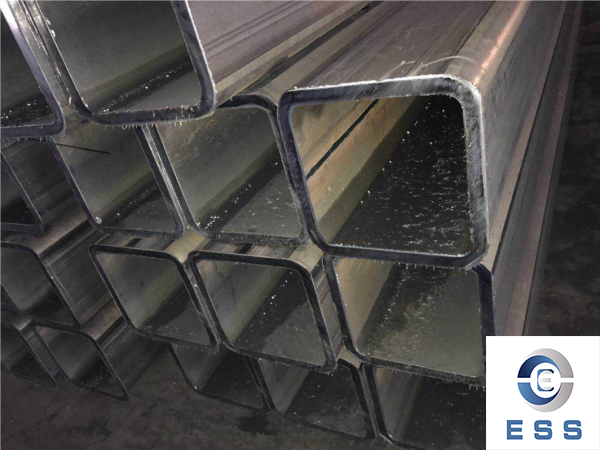

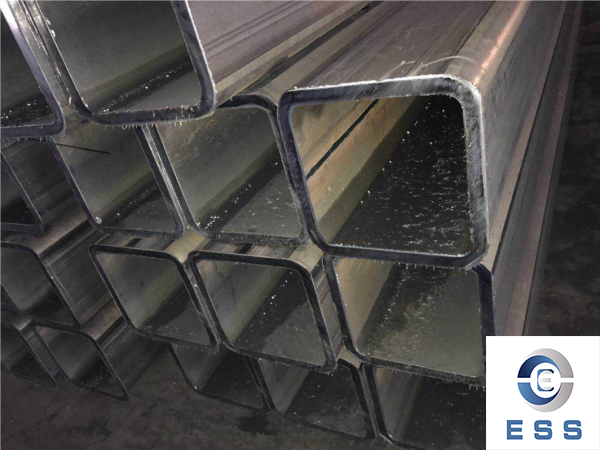

Square tubes are steel tubes with equal side lengths. It is made of strip steel rolled through process treatment. Changing to square tubes: Generally, the strip steel is unpacked, flattened, curled, and welded to form a round tube, which is then rolled into a square tube and then cut to the required length.

Square tube storage method

1. Choose a suitable site and warehouse

(1) The site or warehouse where steel pipes are stored should be located in a clean and well-drained place, away from factories and mines that produce harmful gases or dust. Weeds and all debris should be removed on the site and the steel pipes should be kept clean;

(2) Materials that are corrosive to steel pipes such as acids, alkalis, salts, cement, etc. must not be stacked together in the warehouse. Different types of steel pipes should be stacked separately to prevent confusion and contact corrosion;

(3) Large steel sections, rails, steel plates, large-diameter steel pipes, forgings, etc. can be stacked in the open air;

(4) Small and medium-sized steel, wire rods, steel bars, medium-diameter steel pipes, steel wires and steel wire ropes, etc., can be stored in well-ventilated material sheds, but they must be covered with thatch;

(5) Some small steel pipes, thin steel plates, steel strips, silicon steel sheets, small diameter or thin-walled steel pipes, various cold-rolled and cold-drawn steel pipes, and high-priced, corrosive metal products can be stored in the warehouse;

(6) The warehouse should be selected based on geographical conditions. Generally, ordinary closed warehouses are used, that is, warehouses with walls on the roof, tight doors and windows, and ventilation devices;

(7) The warehouse is required to be ventilated on sunny days, closed to prevent moisture on rainy days, and a suitable storage environment must be maintained at all times.

2. Reasonable stacking, first-in-first-out

(1) The principle requirement for stacking is to stack according to varieties and specifications under the conditions of stable stacking and ensuring safety. Materials of different types should be stacked separately to prevent confusion and mutual corrosion;

(2) It is prohibited to store items that may corrode steel pipes near stacking locations;

(3) The bottom of the stack should be elevated, solid, and flat to prevent the material from getting damp or deformed;

(4) Materials of the same type are stacked separately according to the order in which they are put into storage, so as to facilitate the implementation of the first-in-first-out principle;

(5) Sectional steel stacked in the open air must have wooden pads or strips of stone underneath, and the stacking surface should be slightly tilted to facilitate drainage. Pay attention to the straight placement of the materials to prevent bending and deformation;

(6) The stacking height shall not exceed 1.2m for manual operation, 1.5m for mechanical operation, and the stack width shall not exceed 2.5m;

(7) There should be a certain channel between stacks. The inspection channel is generally 0.5m. The access channel depends on the size of the material and the transportation machinery, and is generally 1.5~2.Om;

(8) The bottom of the stack should be raised. If the warehouse is on a sunny cement floor, the height should be 0.1m; if it is a mud floor, the height should be 0.2~0.5m. If it is an open-air site, the cement floor should be raised by 0.3~O.5m, and the sand and mud surface should be raised by 0.5~O.7m.

(9) Angle steel and channel steel should be stacked in the open air, that is, the mouth should be facing down, and the I-beam should be placed vertically. , the I groove surface of the steel pipe cannot be facing upward to avoid water accumulation and rust.

3. Packaging and protective layer of protective materials

The preservatives or other plating and packaging applied by the steel factory before leaving the factory are important measures to prevent the material from rusting. Care must be taken to protect it during transportation and loading and unloading, and it cannot be damaged, which can extend the storage period of the material;

4. Keep the warehouse clean and strengthen material maintenance

(1) Before putting materials into storage, care should be taken to prevent them from being exposed to rain or mixed with impurities. Materials that have been exposed to rain or stained should be cleaned using different methods according to their properties. For example, wire brushes can be used for high hardness, and cloth can be used for low hardness. , cotton, etc.;

(2) Materials should be inspected frequently after being put into storage. If there is any rust, the rust layer should be removed;

(3) Generally, after the surface of steel pipes is cleaned, there is no need to apply oil. However, for high-quality steel, alloy thin steel plates, thin-walled pipes, alloy steel pipes, etc., after rust removal, both the inner and outer surfaces need to be coated with anti-rust oil before storage;

(4) For steel pipes that are severely corroded, they should not be stored for a long time after rust removal and should be used as soon as possible.

Read more: What does SHS mean in steel terms? or What is the difference between square tube and rectangular tube?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.