Non-metallic inclusions in square tubes

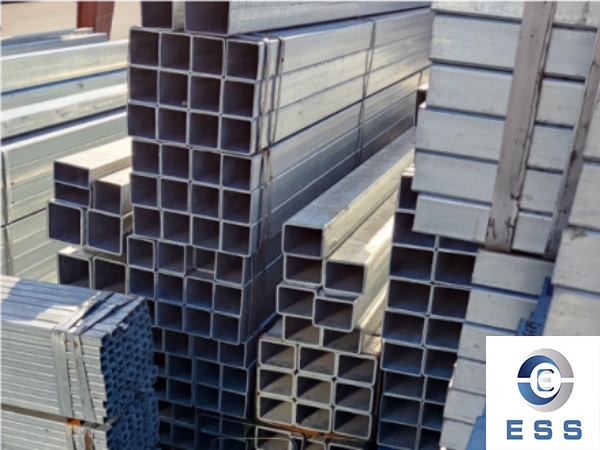

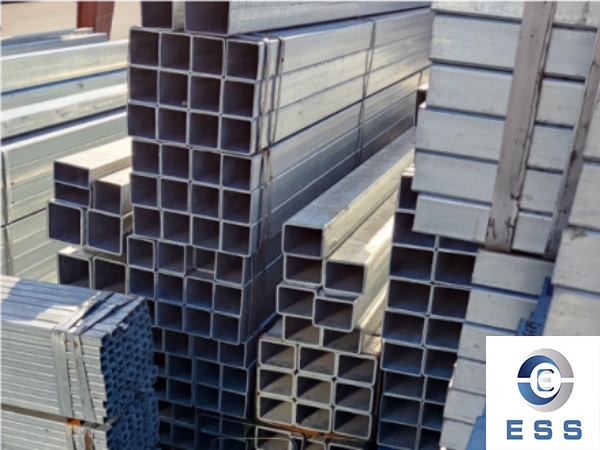

What is a square tube?

Square pipe is a welded structural grade pipe available in Type A513 or A500 Grade B depending on its size and wall thickness. Either grade is ideal for all structural applications, general fabrication, fabrication and repair. Square tubes are widely used in industrial maintenance, farm implements, transportation equipment, truck beds, trailers, frames, etc. Its box configuration provides greater strength and rigidity compared to angles or channels. This steel shape is easy to weld, cut, form and machine with the proper equipment and knowledge.

Determine the characteristics of non-metallic inclusions in square tubes

Although the content of non-metallic inclusions in square pipes is small, it has a great impact on the performance of the pipe, so the detection of non-metallic inclusions has become one of the important items in the production process. A correct understanding of the source, composition, form, hazard principle, distribution and microscopic characteristics of inclusions is of great significance for controlling or reducing the content of inclusions in square and rectangular pipes and improving quality.

To determine the type of non-metallic inclusions in square tubes, you can refer to the following characteristics:

1.Aluminum oxide: Most of them are undeformed, angular, small black or bluish particles, arranged in a row along the rolling direction, with at least three particles.

2.Spherical oxides: undeformed, angular or rounded, small black or bluish in shape, irregularly distributed particles.

3.Single-particle spherical type: single-particle inclusions that are round or nearly round, with a diameter of ≥13 μm.

4.Sulfides: Single gray inclusions with high ductility and a wide range of aspect ratios. In square and rectangular tube materials, the ends are generally rounded.

5.Silicates: have high ductility, have a wide range of aspect ratios, and appear individually as black or dark gray inclusions, generally with sharp ends at sharp angles.

Traditional types of inclusions can also be evaluated by comparing their shape with the five inclusion categories mentioned above and noting their chemical characteristics. The evaluation of deposit phase types such as boride, carbide, carbonitride or nitride in square and rectangular tubes can also be based on their morphology and comparison with the above five types of inclusions, and their chemical characteristics can be expressed according to the above method.

How to extend the service life of SHS?

Square tubes are an indispensable part of construction work. Everyone is very familiar with these. Therefore, the quality of square tubes will directly affect the development trend of the construction industry. What if the service life of square tubes can be made longer? ?

The first method is to carry out anti-rust treatment on the square pipe. When anti-rusting the square pipe, the steel brush is mainly used to polish its surface. This method can effectively remove loose or raised rust on the surface of the square pipe. trace.

The second method is to clean the surface of the square pipe. When cleaning the square pipe, organic solvent or solvent should be used to clean the surface to achieve the effect of removing oil and dust. This method is only suitable for removal methods. The grease and dust on the surface of the pipe cannot remove rust and oxide scale, so this method can only be used as an auxiliary method in anti-corrosion production.

The third method is to pickle and passivate the square tube. When pickling and passivating the square tube, two methods, chemical and electrolytic, are usually used. These two methods will cause the oxidation of the square tube. Remove the skin. It is often divided into two methods. The reason is that chemical water treatment can only clean the surface very completely, and it is difficult to achieve the desired effect in some gaps.

After using chemical pickling and passivation, and then filling it with electrolysis, the square tube can be well protected. The above methods are all very simple ways to extend the service life of the square tube. We As long as it is processed according to these methods, the square pipe can bring great help to us in the whole process of use.

Read more: What does SHS mean in steel terms? or What is the difference between square tube and rectangular tube?

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.