In pipeline engineering, mild

steel pipe and ductile iron pipe are two common materials, which have

significant differences in material composition, strength, corrosion resistance

and service life. This article will compare the two in detail to help choose

the most suitable pipeline material.

Mild steel vs. Ductile iron

1. Mild steel

Mild steel refers to steel with a low carbon content (generally below 0.1%). Its characteristics include good toughness, high machinability, good corrosion resistance, and moderate strength.

Mild steel is typically used to manufacture mechanical parts that do not require high strength but need good toughness and plasticity.

Common standards: ASTM A53, ASTM A106, ASTM A333, API 5L, EN

10210 / EN 10220, etc.

2. Ductile iron

Ductile iron is a casting material made of iron-carbon alloy. Its carbon content is typically between 2% and 4%, much higher than that of low-carbon steel.

Ductile iron is characterized by high hardness, good wear resistance, poor forgeability, and poor machinability. It is generally used to manufacture parts that bear heavy loads and experience wear.

Common standards: ISO 2531, EN 545, EN 598, AWWA C151, GB/T 13295.

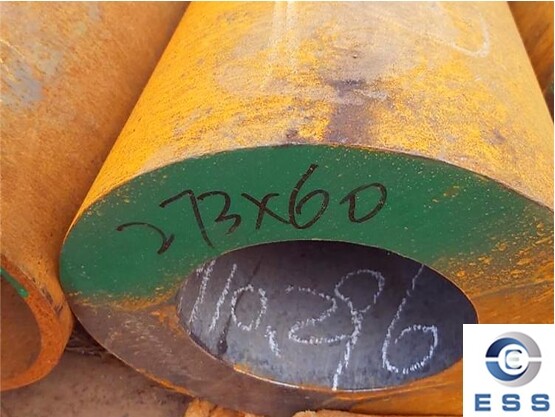

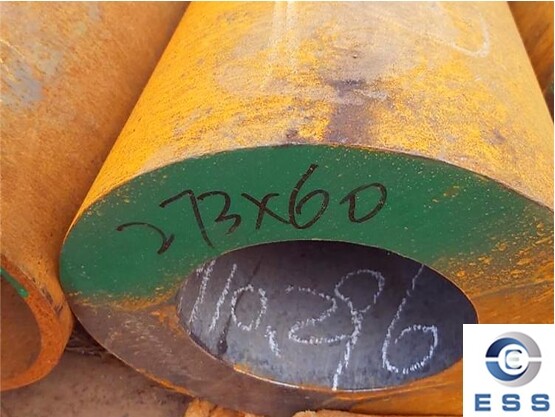

Ductile iron pipe vs Mild steel pipe: Material composition

Mild steel pipe is made of steel with a

carbon content between 0.05% and 0.25%. It is a carbon

steel pipe with high toughness and plasticity. Due to its low carbon

content and excellent welding performance, it is suitable for engineering

scenarios that require high-strength connections.

The material of ductile iron pipe is cast

iron, which is formed by adding elements such as nickel and vanadium to form

ductile iron, thereby improving the strength and toughness of the material. Its

unique structure makes it have both the corrosion resistance of cast iron and

the strength of steel.

|

Comparison items

|

Mild steel pipe

|

Ductile iron pipe

|

|

Carbon content

|

0.05%–0.25%

|

3.0%–4.0%

|

|

Graphite morphology

|

None

|

Spheroidal graphite

|

|

Alloying elements

|

Small amounts of Mn and Si

|

Mg, Si, and Mn

|

|

Microstructure

|

Ferrite / Pearlite

|

Ferrite + spheroidal graphite

|

Ductile iron pipe vs Mild steel pipe: Strength

The strength of mild steel pipe is higher

than that of ductile iron pipe, mainly reflected in tensile strength and

bending strength. Mild steel pipe is often used in engineering occasions with

high pressure, such as transporting oil and natural gas, for OCTG pipe and casing pipe,

etc.

Although the strength of ductile iron pipes

is not as good as that of mild steel pipes, they have excellent pressure

resistance and good impact resistance, making them suitable for municipal water

supply, drainage systems, and low-pressure gas transportation.

|

Performance

|

Mild steel pipe

|

Ductile iron pipe

|

|

Tensile Strength

|

350–550 MPa

|

420–500 MPa

|

|

Yield Strength

|

210–350 MPa

|

≥300 MPa

|

|

Elongation

|

20%–35%

|

7%–12%

|

Ductile iron pipe vs Mild steel pipe: Corrosion resistance

Mild steel pipes have poor corrosion

resistance and are easily corroded and oxidized in humid or chemically

corrosive environments. Therefore, when using mild steel pipes, additional

anti-corrosion measures such as coating or galvanizing are usually required.

Ductile iron pipes have good corrosion

resistance and can resist erosion by soil, moisture, and chemicals, making them

particularly suitable for use in engineering occasions such as high-speed

railway subgrades.

Ductile iron pipe vs Mild steel pipe: Service life

The service life of mild steel pipes is

about 20 years. If the environment is highly corrosive and no effective

anti-corrosion measures are taken, their service life may be greatly shortened.

The service life of ductile iron pipes can

reach more than 40 years, and their long life makes them an ideal choice for

municipal engineering and infrastructure construction.

How to distinguish between mild steel pipes

and ductile iron pipes

1. By Appearance

Mild steel has a smoother surface, uniform

color, and finer grains, while ductile iron has a rougher surface and may

contain graphite spots.

2. By Hardness Testing

Mild steel has a lower hardness, generally

below HRB80, while ductile iron has a higher hardness, usually above HB170, and

some can even reach above HB300.

3. By Application

Mild steel is mainly used to manufacture

some light mechanical parts, while ductile iron is usually used to manufacture

some heavy or stress-bearing parts.

Ductile iron pipes vs. Mild steel pipes:

Selection recommendations

1. Typical Scenarios for Choosing Mild Steel

Pipes

Oil, natural gas, and high-pressure steam

pipelines

Industrial fluid transportation

Piping systems requiring welding or

customization

High mechanical stress or earthquake-prone

areas

2. Typical Scenarios for Choosing Ductile

Iron Pipes

Municipal water supply and drainage

networks

Underground buried projects

Projects requiring long-term operation and

low maintenance

Medium and low-pressure transmission

systems

Summary

In summary, mild steel pipes and ductile

iron pipes have their own advantages and disadvantages, and should be selected

according to the needs of specific projects. In practical applications, it is

necessary to fully consider factors such as material strength, corrosion

resistance, and service life, and to carry out reasonable design and use.

Read more: Difference between mild steel pipe and carbon steel pipe or Mild steel pipe VS. Carbon steel pipe

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.