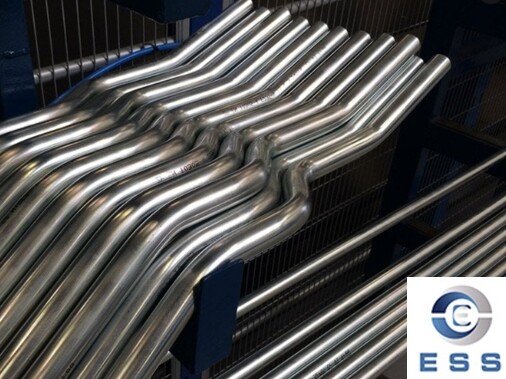

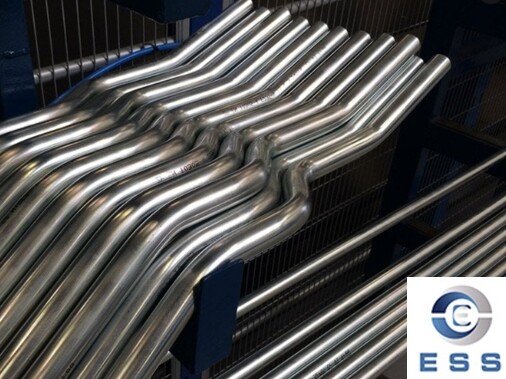

Hydraulic

tubes are used to transport fluids to hydraulic components, accessories, valves, flanges and

other tools, which sometimes cause oil leakage. There are many reasons for

hydraulic tube leakage, which may be due to skewed or damaged pipe connections,

or aging of seals. Therefore, before handling the oil leakage, you must first

find out the cause of the oil leakage and then handle it accordingly.

The reasons for hydraulic tube joints to

leak may include:

1. Compression joints: The pipe is

subjected to external force or impact, causing the compression joints to loosen

or the pipe end face to deform.

2. Flared pipe joints: Excessive flaring,

substandard quality or multiple disassembly, resulting in flaring deformation

or cracks.

3. Sealing ring problem: The sealing ring

is aged, deformed, not assembled in place or not compacted, resulting in poor

sealing.

4. External force impact: The pipe is

subjected to large external force or impact, causing the compression joints to

loosen or the pipe end face to deform.

So how to solve the problem of hydraulic tube joints leaking?

1. Replace the seal

If the cause of the oil leakage is aging or

damage to the seal, then the seal needs to be replaced. When replacing seals,

you need to pay attention to choosing the right seals and strictly follow the

prescribed methods to replace them. Or use epoxy resin for sealing, which can

quickly fill the holes and form a strong sealing layer. Use a pressure belt to

wrap the belt around the leak of the oil pipe to form pressure, thereby

reducing oil leakage.

2. Re-tighten the connection

If the cause of the oil leakage is that the

pipe connection is skewed or not tightened, then you need to re-tighten the

connection. Before re-tightening, you need to check whether the connection is

flush and use the correct tools to tighten it. Check whether the pipeline is

subjected to external force or impact force, and eliminate the influence of

external force.

3. Repair damaged pipelines

If the cause of the oil leakage is that the

pipeline is damaged, then it needs to be repaired. Pipeline repair can be

carried out by welding, glue bonding and other methods. Welding repair requires

draining the oil in the hydraulic oil tank, using an angle grinder to finely

grind the area around the oil leak until the metallic luster is exposed, and

finally using two-protection welding or welding rod manual arc welding for

welding repair.

4. Replace the leaking pipeline

If the leaking pipeline cannot be repaired,

then the leaking pipeline needs to be replaced. When replacing the pipeline,

you need to pay attention to choosing the appropriate pipeline and strictly

follow the prescribed method to replace it.

5. Use hydraulic joints

The hydraulic joint is a part specially

used to connect and seal hydraulic tubes, which can effectively prevent oil

leakage. The hydraulic joint is simple to install, can be quickly disassembled

and replaced, and the repair effect is stable and reliable.

Summary

During the process of hydraulic tube oil

leakage treatment, you need to pay attention to safety. First of all, operators

should be prohibited from contacting the leaking liquid to avoid accidents.

Secondly, prepare the corresponding tools and materials, and operate in strict

accordance with the operating procedures. Hydraulic tube oil leakage treatment

is a routine maintenance work, which is very important for maintaining the

stable operation of the hydraulic system. During the oil leakage treatment process,

pay attention to safety to ensure the personal safety of operators and the

integrity of equipment.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.