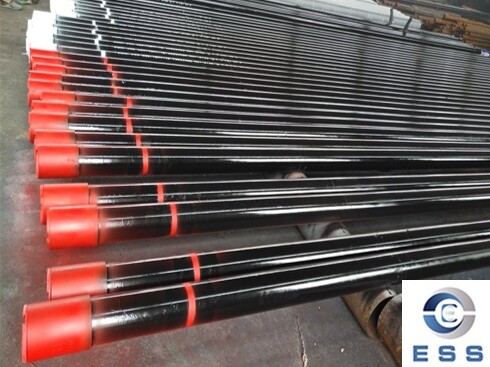

Casing pipe is

an OCTG pipe,

usually made of steel, with an outer layer covered with environmentally

friendly plastic or other materials. Lowering casing pipe means that during the

drilling process, a casing pipe is built into the wellhead to protect the well

wall and maintain the integrity of the wellbore. It is also a prerequisite for

the next step of cementing.

Purpose of lowering casing pipe

1. Protect the well wall: The drill bit

will wear the well wall during the drilling process, and lowering casing pipe

can protect the well wall from being worn.

2. Maintain the integrity of the wellbore:

After the casing pipe is lowered, it can maintain the integrity of the well

wall and prevent the well wall from collapsing.

3. Improve drilling efficiency: Lowering casing

pipe can shorten drilling time and improve drilling efficiency.

Reasons for encountering resistance when

lowering casing pipe

Obstruction when lowering casing pipe is a

common problem in drilling. The main reasons include:

1. Formation gravel, mud, oil layer

rupture, etc. cause pipe string obstruction.

2. Insufficient, excessive, or too small

drilling fluid flow leads to abnormal operation of the pipe string.

3. The drill bit drills into the formation,

generating debris or blockage.

Solutions

1. Increase drilling fluid flow: When

lowering casing pipe encounters resistance, it can be solved by increasing the

drilling fluid flow. This can increase the running speed of the pipe string,

thereby destroying the formation gravel or debris, etc., making it easy to pass

through the pipe string.

2. Change the type of drilling fluid:

Changing the type of drilling fluid can also solve the problem of encountering

resistance when lowering casing pipe. For example, the formation gravel or

debris can be destroyed by increasing the viscosity of the drilling fluid,

making it easy to pass through the pipe string.

3. Use professional tools: During the

drilling process, if the casing pipe is blocked, professional tools can be used

to solve the problem. For example, a drill string vibrator can be used to break

up formation gravel or debris, etc., so that it is easy to pass through the

pipe string; or a pipe string cleaner can be used to remove impurities and

debris in the pipe string.

4. Take other measures: In addition to the

above methods, other measures can be taken to solve the problem of resistance

when lowering the casing pipe. For example, the formation gravel or debris can

be broken by increasing the drill bit speed or changing the drill bit shape, so

that it is easy to pass through the pipe string.

Summary

In short, it is a common problem to start

the pump when the casing pipe is blocked during drilling, but this problem can

be solved through the above solutions. Of course, for specific situations,

corresponding measures need to be taken according to the actual situation.

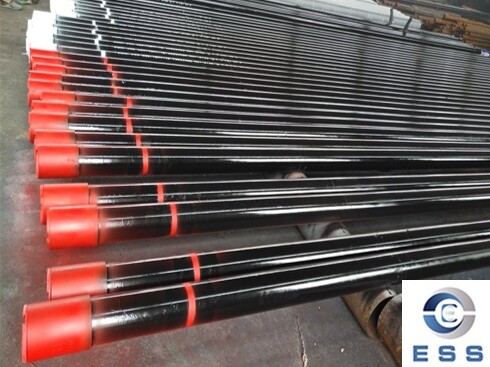

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.