Full body normalized heat treated large diameter steel pipe

Among the pipeline steel pipe standards, whether it is API Spec 5L-2018 "Pipeline Steel Pipe Specification", ISO 3183: 2012 "Petroleum and Natural Gas

Steel Pipes for Gas Industry Pipeline Transportation Systems" or GB/T 9711-2017 "Steel Pipes for Oil and Gas Industry Pipeline Transportation Systems". For

LSAW steel pipes with manufacturing grade level PSL2 and steel grade L290N, the delivery status is positive In the fire state (N state), two processes are allowed: ① Using normalized or normalized rolled steel plates, cold forming pipe making, and the steel pipes are no longer heat treated after pipe making; ② Using rolled state, thermo-mechanical rolling Steel plates are made (TMCP), normalized rolled or normalized, and cold formed into pipes. After pipe making, the steel pipes need to be normalized and heat treated. The steel pipe manufacturer mainly selects solutions based on the customer's agreement. If the customer does not have clear requirements, the steel pipe manufacturer will make its own choice. In engineering practice, in order to avoid serious deformation of the pipe shape caused by the overall normalizing heat treatment of the steel pipe, most of the large-diameter submerged arc welded pipes delivered in the normalized state choose the former option. Customers who choose the overall heat treatment solution for the whole pipe body are generally based on their usage habits and preferences, but this preference choice is extremely challenging for steel pipe manufacturers.

As we all know, the overall heat treatment of steel pipes can easily lead to deformation of steel pipes. The steel pipes selected for overall heat treatment are mainly small-diameter high-frequency welded pipes and seamless steel pipes. The overall heat treatment solution for large-diameter submerged arc welded pipes is mainly recommended by some customers in North America, the Middle East, and Central Europe. In view of the fact that the large-diameter-thickness ratio (diameter D/wall thickness T) at high temperatures seriously affects the out-of-round shape of the steel pipe. For high degree of accuracy and straightness, post-welding annealing at 590~680℃ is required to eliminate stress. There are few research literature reports on overall normalizing heat treatment of large-diameter submerged arc welded pipes.

A large petrochemical enterprise ordered a batch of L290N LSAW steel pipes with specifications of φ711 mmx15.88mm and φ914.mmx17.48 mm from the company, which are used for 2.2MPa 300~350 ℃ steam transportation. Steam pipes mainly bear the temperature and pressure of superheated steam in the pipes, work under creep conditions, and also bear low cycle fatigue loads. my country's SH/T 3059-2012 "Specifications for the Selection of Petrochemical Pipeline Design Equipment" lists the operating temperatures of commonly used steel materials for steam pipelines, among which high-quality carbon structural steel

20G can be used under the conditions of -20~450℃. If it exceeds 450℃, low alloy steel and high alloy steel need to be selected. Compared with 20G, the choice of L290N can not only meet the strength and toughness indicators required for steam transportation in this project, but also meet the excellent weldability required for pipeline circumferential welding. This petrochemical enterprise prefers the normalizing heat treatment solution for the entire pipe after welding the steel plate pipe. The technical standards comply with GB/T 9711-2017 and API Spee 5L-2018. The upper limit of chemical composition requirements is shown in Table 1, and the mechanical property requirements are shown in Table 2; steel pipe The out-of-roundness requirement is that the difference between the maximum outer diameter and the minimum outer diameter is ≤0.6%D (D is the outer diameter of the steel pipe) and ≤13mm; the straightness requirement of the steel pipe is ≤3.2 mm/3 m. There are two difficulties in the development of this LSAW steel pipe: ① Use TMCP steel plate to cold form the pipe and then normalize heat treatment to ensure the tensile properties, especially the yield strength; ② Large diameter to thickness ratio (D/T Reaching more than 45) The problem of ensuring out-of-roundness and straightness of LSAW steel pipes after normalizing.

|

Table 1 Required upper limit of chemical composition (mass fraction) of L290N longitudinal submerged arc welded pipe ① %

|

|

C

|

Si

|

Mn②

|

P

|

S

|

V

|

Nb

|

Ti

|

|

0.24

|

0.40

|

1.20

|

0.025

|

0.015

|

0.05

|

0.06

|

0.04

|

|

Note: ① The upper limit of carbon equivalent requirement is 0.43%; ② For every 0.01% decrease in C content, the upper limit of Mn content can be increased by 0.05%, with a maximum value of 1.65%.

|

|

Table 2 Main mechanical property requirements of L290N straight seam arc welded pipe

|

|

Pipe tensile properties①

|

Weld tensile strength

Rm③/MPa

|

Charpy impact energy at 0℃④/J

|

Hardness

HV10⑤

|

|

Yield Strength

Rt0.5/MPa

|

Tensile strength

Rm/MPa

|

Yield strength ratio

|

Elongation

A50mm②/%

|

Tube body

|

Weld seam and heat affected zone

|

|

290~495

|

415~655

|

≤0.85

|

≥23

|

415~655

|

Single value≥30

Average value≥40

|

Single value≥21

Average value≥27

|

≤250

|

|

Note: ① Take transverse and round bar tensile specimens; ② The original gauge length is 50 mm; ③ Take transverse and plate-shaped tensile specimens; ④ V-notch specimens; ⑤ Refers to the weld, heat-affected zone and base metal Vickers hardness.

|

In view of the above two difficulties, the design composition, structure and performance of the L290N LSAW steel pipe are experimentally studied, and the company's advantages of consistent production and rapid response in the whole process are fully utilized to achieve the normalizing heat treatment of the L290N straight seam L290N straight seam full pipe body with a large diameter to thickness ratio. Bulk supply of submerged arc welded pipes.

1. Experimental research plan

1.1 Laboratory composition design and normalizing heat treatment process research The American Society for Testing and Materials believes that for pressure vessels, the power consumption

For fusion-welded carbon-manganese steel pipes, the composition design of different temperature service environments and steel grades should be different. Regarding the chemical composition of carbon steel plates for pressure vessels, ASTM A 515/A 515M-2010 (R2015) "Standard Specification for Carbon Steel Plate for Medium and High Temperature Pressure Vessels" and ASTM A 516/A 516M-2017 "Medium and Low Temperature Pressure "Standard Specification for Carbon Steel Plate for Vessels" stipulates that for steel used for medium and low temperature pressure vessels, its chemical composition is designed to be mainly medium-low carbon and medium-low manganese. The content of C and Mn increases with the increase of steel grade and steel plate thickness. , P, S, and Si contents are controlled within a certain range; for steel used for medium and high temperature pressure vessels, the chemical composition must strictly control the amount of Mn added, the minimum allowable yield strength is 240 MPa and below, and the upper limit of Mn content is controlled to 0.98%, the minimum When the allowable yield strength is 260 MPa, the upper limit of Mn content is increased to 1.30%. The principle of reducing C and increasing Mn is applicable, and the maximum Mn content shall not exceed 1.65%. This is because excessive Mn content is not beneficial to the high-temperature properties of steel, especially the creep properties. Considering the weldability of the transportation welded pipeline pipe, a smaller carbon equivalent should be designed, so the contents of C and Mn should not be too high; however, considering the low yield-strength ratio requirements after heat treatment, the contents of C and Mn should not be too low either. . On the other hand, the structural genetic effect of steel during heat treatment, refining the original organizational grains has a positive effect on improving the properties of steel after heat treatment.

Meaning, the author plans to use controlled rolling technology to produce thick plates for welded pipes; therefore, based on the C and Mn components, a small amount of micro-alloying elements such as Nb are added to refine the grains and increase the thermal stability of the material's tensile strength.

The test steel adopts C-Mn-Nb system, that is, a trace amount of Nb element is added on the basis of the chemical composition of low carbon medium manganese steel, ω (Nb) <0.06%. The chemical composition of the test steel is: C content 0.08%~0.20%, Si content 0.12%~0.32%, Mn content 1.20%~1.60%, Nb content 0.010%~0.050%.

A 500 kg induction melting furnace is used to cast a billet with a size of 250mmx230 mmx220 mm. The TMCP process is used to roll the 250 mm thick steel billet into a steel plate with a thickness of 18 mm on the hot rolling mill of the pilot production line. The steel plate size is 2114 mmx342 mmx18mm. Remove about 200 mm from the head and tail of the rolled steel plate, and then cut out three tile samples with dimensions of 342 mmx100 mmx18 mm on the steel plate. One piece should be kept in the TMCP state (sample No. 1), and the other two pieces should be processed. Normalizing heat treatment tests at different temperatures (samples No. 2 to 3), and the remaining samples are used for temperature-thermal expansion coefficient curve measurement.

The tangent method is used to analyze the phase change point of the static phase transition of the material during the heating and cooling processes, and the phase change point temperatures Ac3, Ac1, Ar1 and Ar3; etc. are respectively calculated and compared with the measured values. See Table 3 for details. As can be seen from Table 3, the measured phase change point temperature Ac3 is 841°C, which is consistent with the theoretical calculated value of 840°C, indicating that empirical formulas can be used to calculate the static phase change point of this type of material.

|

Table 3 Comparison of thermal simulation measured values and theoretical values of phase transition point of steel with designed composition ℃

|

|

Phase change point

|

Ac1

|

Ac3

|

Ar1

|

Ar3

|

|

Actual value

|

726

|

841

|

622

|

790

|

|

Theoretical calculation value

|

-

|

840

|

-

|

756

|

The holding temperature of the heat treatment process system can be determined according to the phase change point temperature. Normalizing temperature is usually Ac3+30~50 ℃. Considering that it is difficult to control the pipe shape of large-diameter steel pipes after normalizing, a lower temperature should be selected within this range. In industrial practice, the temperature of the heating furnace usually fluctuates by +10°C, so the situation where the temperature is 10°C lower than the lower limit of the normalizing temperature range should also be examined. In view of this, 860°C and 880°C were selected as the temperature points for normalizing test research. The process system is as follows: heat samples No. 2 to 3 to 860°C and 880°C respectively, keep warm for 25 minutes, and then air-cool. After the test is completed, the microstructure and properties of the test steel are analyzed, and the 12.7mm tensile specimen and the transverse Charpy impact specimen from the transverse round bar are taken for analysis.

1.2 Research on normalized steel pipe shape control

In order to break through the "bottleneck" of production quality and avoid risks caused by hasty mass production, large-diameter TMCP pipeline steel pipes are prone to severe oxide scale after normalizing heat treatment at high temperatures, excessive out-of-roundness caused by collapse under their own weight, and uneven heating and cooling. Due to poor straightness, two specifications of 914mmx17.48 mm steel pipes (2 steel pipes) with the largest diameter-to-thickness ratio were selected for industrial testing. Conduct planning and research on heating furnace type, holding time control, furnace installation technology and steel pipe finishing.

2. Test results and analysis and discussion

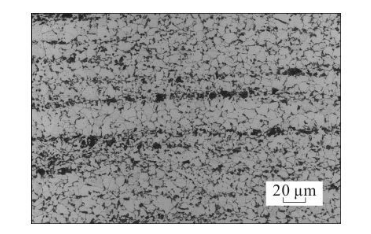

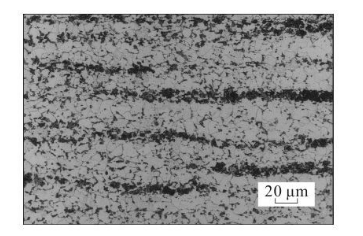

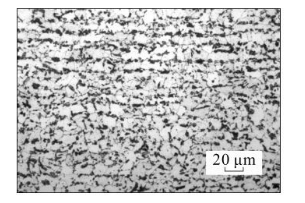

2.1 Organizational analysis

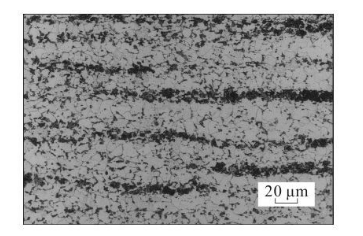

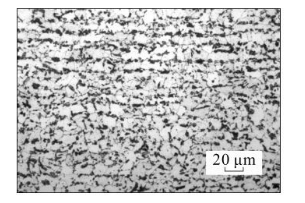

The metallographic structure of the test steel after normalizing is shown in Figure 1, which is a typical ferrite + pearlite structure. The ferrite grain size of samples No. 2 and No. 3 are both greater than grade 8, and the pearlite aggregates in a band shape; as the normalizing temperature increases, the structure of sample No. 3 after normalization is slightly coarser. After the steel plate is cold-formed into a steel pipe, the Bauschinger effect of this type of structure is obvious; therefore, rod-shaped specimens should be used for tensile tests as much as possible on the base material to reduce the loss of yield strength caused by the flattening process of plate-shaped specimens. .

(a) Sample No. 2, normalized at 860°C

(b) Sample No. 3, normalized at 880°C

Figure 1 Metallographic structure of test steel after normalizing

2.2 Mechanical property evaluation

2.2.1 Room temperature stretching

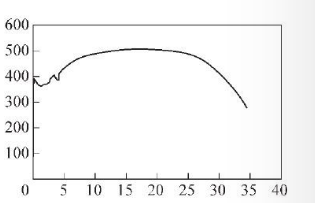

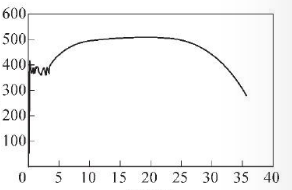

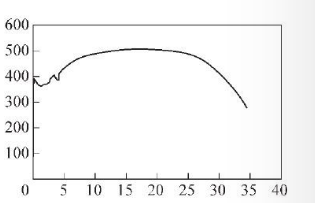

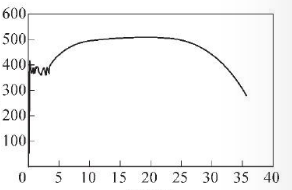

The room temperature tensile properties of the test steel before and after normalizing are shown in Table 4. It can be seen that the room temperature tensile properties of the test steel after normalization meet the target requirements; compared with the properties of the TMCP state specimen, the yield strength and tensile strength of the normalized specimen decreased significantly, by about 60 MPa. The tensile test curve of the test steel after normalizing is shown in Figure 2. It can be seen from Figure 2 that the test steel has a yield platform exceeding 1.5% strain after normalizing heat treatment. When the cold shaping ratio does not exceed 1.5% after heat treatment, its yield strength can still fall on the yield platform and can meet the L290N steel grade. The tensile strength requirements create conditions for the deformation finishing of the entire steel pipe body after normalizing.

|

Table 4 Room temperature tensile properties of test steel before and after normalizing

|

|

Sample No

|

Rt0.5/MPa

|

RcL/MPa

|

Rm/MPa

|

A50mm/%

|

Yield strength ratio

|

|

1

|

433

|

-

|

559

|

33

|

0.77

|

|

2

|

371

|

362

|

506

|

34

|

0.73

|

|

3

|

377

|

361

|

508

|

35

|

0.73

|

|

Product requirement

|

290~495

|

-

|

415~655

|

≥23

|

≤0.85

|

(c) Sample No. 2, normalized at 860°C

(d) Sample No. 3, normalized at 880°C

Y: Stress/MPa

X: strain/%

Figure 2 Tensile test curve of test steel after normalizing

2.2.2 Impact toughness

The Charpy impact properties of the test steel before and after normalizing are shown in Table 5. It can be seen that the -20 C impact performance of the test steel before and after normalizing does not change much. The minimum value of the average impact energy is 396 J, and the minimum value of the single value of impact energy is 390 J, which is far beyond the customer standard requirements. From this point of view, the normalizing temperature has a limited impact on the normalizing performance of the test steel.

|

Table 5 Charpy impact properties of test steel before and after normalizing J

|

|

Sample No

|

-20℃Impact energy

|

-40℃Impact energy

|

|

1

|

2

|

3

|

Average value

|

1

|

2

|

3

|

Average value

|

|

1

|

390

|

408

|

401

|

400

|

-

|

-

|

-

|

-

|

|

2

|

397

|

400

|

396

|

398

|

390

|

408

|

401

|

400

|

|

3

|

398

|

405

|

399

|

401

|

396

|

379

|

398

|

391

|

|

Note: According to customer requirements, under the condition of 0 ℃, the minimum value of the single value of impact energy is 30 J and the minimum value of the average value is 40.

|

2.3 Steel pipe shape table and geometric size evaluation

Samples were taken from two test tubes in the industrial test and physical and chemical properties were analyzed. The analysis results all met the requirements of relevant standards.

2.3.1 Selection of steel pipe normalizing heat treatment furnace

Taken together, in order to take into account both production efficiency and product quality, the selection of normalizing heat treatment furnace for large-diameter UOE welded pipes should follow the following principles.

(1) Because normalizing heat treatment is required, a heat treatment furnace with a temperature up to 1000°C should be selected first. The furnace temperature is required to be uniform to avoid excessive local temperature. The heat transfer mode of this type of heat treatment furnace is mainly radiation and supplemented by convection.

(2) Adhere to the concept of green environmental protection and choose a heat treatment furnace with natural gas as the heating medium.

(3) Adopt periodic heat treatment process, in which the trolley-type heating furnace has the characteristics of simple operation and strong size adaptability.

(4) In order to reduce oxidation of the pipe surface, choose a heating furnace with a reducing atmosphere as much as possible.

(5) The degree of automatic control is high. It can automatically record the temperature curve and has a temperature fluctuation alarm device. The temperature fluctuation is controlled at +10℃.

2.3.2 Steel pipe surface evaluation

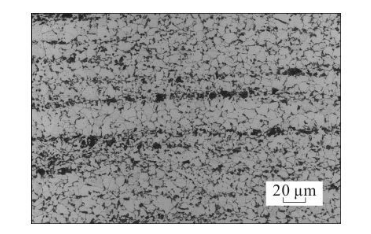

L290N adopts the C-Mn-micro-Nb composition system, controls the actual normalizing and insulation temperature at 860~880°C, and has a maximum surface oxide thickness of 0.15 mm (Figure 3). It is easy to clean in the subsequent high-pressure compressed air purge. Defects such as dents will occur during tube finishing. The near-outer surface structure morphology of the test tube after normalizing is shown in Figure 4. The structure is polygonal ferrite + pearlite, and the pearlite band structure in the controlled rolling state is weakened; the surface hardness distribution is 135~150 HV10, which is much lower to the required 250 HV10.

2.3.3 Effect of steel pipe geometric size control.

Use a C-shaped shelf to support the stacking so that the steel pipes do not come into contact with each other in the heating furnace. On the one hand, it can prevent the risk of collapse of the steel pipes after stacking, and on the other hand, it can make the steel pipes evenly heated. The out-of-roundness of the steel pipe end after normalizing is ≤2.5%D, and the out-of-roundness after finishing meets the requirements of ≤0.6%D; the straightness of the entire length of the 12m long steel pipe is ≤0.25%L (L is the length of the steel pipe), and the straightness after finishing ≤3.2 mm/3 m requirement.

3. Batch application

At present, the company has the conditions for mass production of L290N LSAW steel pipes with full pipe body normalized heat treatment. The process is as follows: making molten steel

Pretreatment → Converter LF-RH vacuum cycle degassing and refining → Continuous casting → Thick plate TMCP rolling → Steel plate flaw detection → UOE forming → Double-sided submerged arc welding → Normalizing heat treatment → Shaping → Hydrostatic test → X-ray inspection (pipe end Filming/Full-length RT-ray inspection) → Full-length UT ultrasonic inspection of weld → UT ultrasonic delamination inspection of pipe end → Magnetic particle inspection of pipe end bevel surface → Appearance and geometric size inspection → Weighing and length measurement → Marking and packaging (spray labeling And ribbons, protective covers, cloth) → shipped. According to the above process flow, the company supplies batches of L290N711 mmx15.88mm LSAW steel pipes 3.2km and 914 mmx17.48mm LSAW steel pipes 3.5 km, a total of about 2300t, used for the transportation of 2.2 MPa, 300~350 C steam . The product's physical and chemical properties, non-destructive testing quality, surface quality and geometric dimensions all meet the technical specifications.

Figure 3 Oxide scale of test tube after normalizing

Figure 4 Microstructure morphology of the near outer surface of the test tube after normalizing

4.Conclusion

(1) TMCP pipeline steel plates are prone to problems such as reduced yield strength and steel pipe deformation when the entire pipe body is normalized and heat treated after UO pipe making. Therefore, the problem of yield strength reduction needs to be solved through reasonable composition design and tensile specimen selection, and measures need to be taken to avoid collapse and deformation of the steel pipe in the heating furnace.

(2) Using L290N pipeline steel plate with C-Mn-micro Nb composition system, after TMCP rolling, both ferrite and pearlite are obtained.

The phase structure has an obvious tensile yield platform. After normalizing and heat treatment, the yield strength is reduced by about 50MPa, but the obvious yield platform is still maintained. Cold shaping is performed with a cold deformation rate within 1.0%, and the rod-shaped sample meets the minimum yield when stretched. The strength requirement of 290 MPa, the out-of-roundness and straightness of the steel pipe can meet the GB/T9711-2017 standard and customer requirements.

(3) Mass production of full pipe body normalized heat treatment 711mmx15.88 mm and φ914 mmx17.48 nmm specifications straight seam submerged arc welding

Pipe, its mechanical properties and geometric dimensions meet the GB/T 9711-2017 standard and customer requirements.

(4) Although the L290N long-diameter-thickness ratio L290N LSAW steel pipe with full pipe body heat treatment has successfully achieved commercial supply, the use of normalized steel plates for direct cold forming without heat treatment of the whole pipe after welding is also in compliance with GB/T9711- 2017 and API Spec 5L-2018 requirements on the delivery status of normalized steel pipes. From a manufacturing perspective, it is recommended that for steel pipes delivered in a normalized state, try to avoid using the whole pipe body without fully grasping the changing laws of steel plate-steel pipe strength and toughness and the pipe shape control technology of large diameter-thickness ratio steel pipes after integral normalization. Normalizing heat treatment program.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.

Eastern Steel Manufacturing Co.,Ltd not only improve product production and sales services, but also provide additional value-added services. As long as you need, we can complete your specific needs together.